Understanding the Revolutionary Impact of Expandable Microspheres in Materials Science

Expandable microspheres represent one of the most significant innovations in materials science, fundamentally transforming how we approach material development and modification. These remarkable particles, consisting of a thermoplastic shell encapsulating a hydrocarbon blowing agent, possess the unique ability to dramatically expand when exposed to heat. This expansion capability makes expandable microspheres invaluable in various industries, from automotive manufacturing to construction materials.

The interaction between expandable microspheres and host materials creates fascinating changes in texture and density, opening new possibilities for product development and material enhancement. As these microscopic spheres expand, they introduce controlled void spaces within the material matrix, leading to significant modifications in physical properties while maintaining structural integrity.

The Science Behind Expandable Microspheres

Chemical Composition and Structure

At their core, expandable microspheres feature a sophisticated design. The outer shell typically consists of acrylonitrile or other specialized polymers, carefully engineered to maintain stability under normal conditions while responding predictably to heat activation. Inside, the hydrocarbon-based blowing agent remains stable until the activation temperature triggers expansion.

The precise engineering of these microspheres ensures controlled expansion ratios, typically ranging from 40 to 60 times their original volume. This predictable behavior makes them ideal for various industrial applications where precise density control is crucial.

Activation and Expansion Process

When exposed to their specific activation temperature, expandable microspheres undergo a remarkable transformation. The thermoplastic shell softens precisely as the internal hydrocarbon converts to gas, causing the microsphere to expand dramatically. This process occurs without breaking the shell, maintaining the integrity of each particle while creating the desired void space.

The expansion process is particularly noteworthy for its uniformity and controllability. By carefully selecting activation temperatures and microsphere grades, manufacturers can achieve highly specific density reductions and textural modifications in their materials.

Effects on Material Texture

Surface Modifications

The incorporation of expandable microspheres significantly influences material surface characteristics. As these spheres expand, they create microscopic patterns across the material surface, potentially enhancing grip properties and tactile appeal. This effect is particularly valuable in applications requiring specific friction coefficients or aesthetic finishes.

The texture modification can range from subtle to pronounced, depending on microsphere concentration and expansion parameters. Industries often leverage this characteristic to create customized surface finishes without additional processing steps.

Internal Structure Changes

Beyond surface effects, expandable microspheres fundamentally alter the internal structure of materials. The expanded spheres create a network of evenly distributed void spaces, resulting in a unique cellular structure. This internal modification contributes to improved insulation properties and enhanced material performance in various conditions.

The uniform distribution of expanded microspheres ensures consistent material properties throughout the product, avoiding weak points or density variations that could compromise performance.

Impact on Material Density

Controlled Density Reduction

One of the most significant advantages of expandable microspheres lies in their ability to achieve precise density reductions. Manufacturers can target specific density ranges by controlling microsphere concentration and expansion parameters. This precision allows for optimized material properties while minimizing weight.

The density reduction capabilities typically range from 15% to 70%, depending on application requirements and microsphere specifications. This substantial reduction in material density often translates to significant cost savings in raw materials and transportation.

Density Distribution Patterns

The distribution of expandable microspheres within materials creates unique density patterns that can be engineered for specific applications. Strategic placement and concentration gradients allow for targeted density modifications, enabling designers to optimize material performance in critical areas while maintaining overall structural integrity.

These engineered density patterns prove particularly valuable in applications requiring specific weight distribution or localized property modifications, such as automotive components or specialized packaging materials.

Industrial Applications and Benefits

Manufacturing Advantages

The integration of expandable microspheres into manufacturing processes offers numerous advantages. Beyond weight reduction, these materials enable improved processing efficiency, reduced energy consumption, and enhanced product consistency. Manufacturers particularly appreciate the ability to achieve complex material properties through a single additive.

The cost-effectiveness of using expandable microspheres often exceeds traditional density reduction methods, making them an increasingly popular choice across various industries.

Performance Enhancements

Materials modified with expandable microspheres frequently demonstrate superior performance characteristics. Enhanced thermal insulation, improved acoustic properties, and better impact resistance are common benefits. These improvements often come without sacrificing other critical material properties, making expandable microspheres a versatile solution for complex engineering challenges.

The ability to maintain or enhance performance while reducing weight makes these materials particularly valuable in transportation and construction applications where efficiency is paramount.

Frequently Asked Questions

What temperature range triggers expandable microsphere activation?

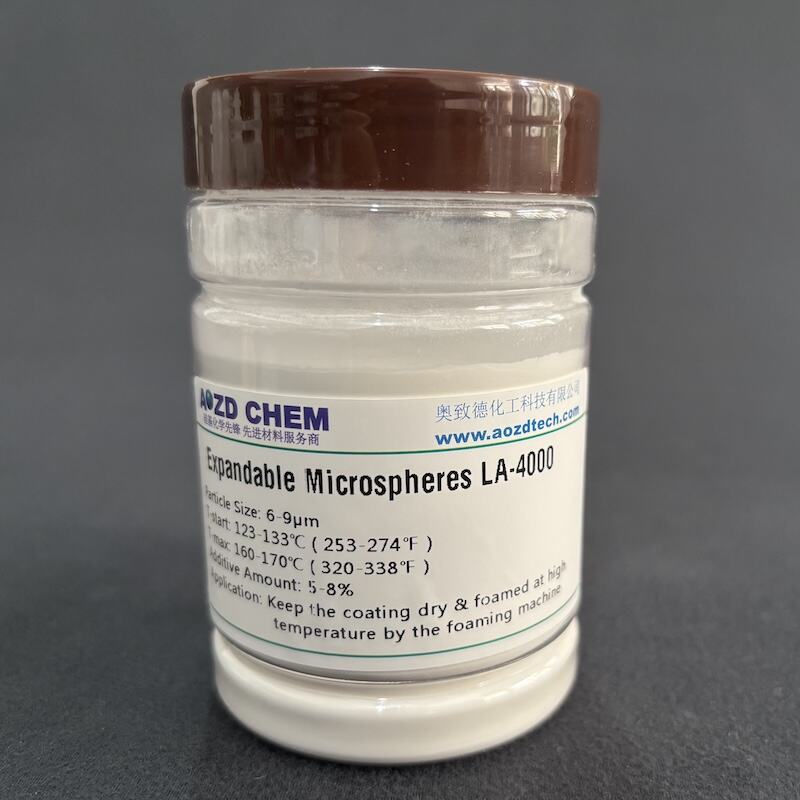

Expandable microspheres typically activate within specific temperature ranges, usually between 80°C and 200°C, depending on the grade. Different variants are available for various application requirements, with some specialized grades designed for lower or higher activation temperatures.

How long do the effects of expandable microspheres last?

Once properly activated and integrated into a material, the effects of expandable microspheres are permanent. The expanded structure remains stable under normal conditions, maintaining the modified density and texture properties throughout the material's lifetime.

Can expandable microspheres be used in food packaging materials?

Certain grades of expandable microspheres are specifically designed and approved for food contact applications, meeting relevant regulatory requirements. However, it's essential to select appropriate grades and verify compliance with applicable food safety standards.