Understanding Compact Expandable Microsphere Technology

Core Composition and Mechanism

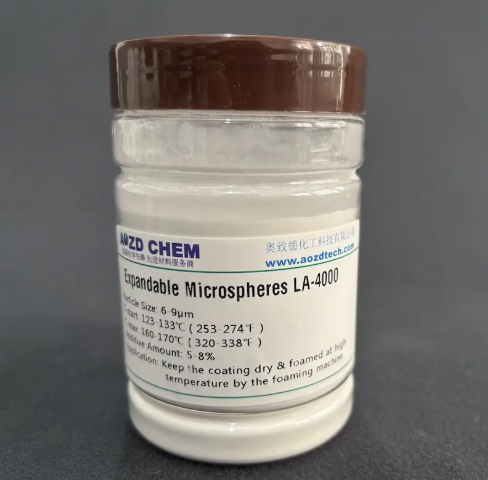

The basic formulation to be used for compact expanding microspheres is a combination of polymers and additives designed to give the best possible expansion properties. These spheres are generally hollow thermoplastic spheres filled with a gas that expands with heat, so when the spheres are subjected to heat, they expand quite a lot. Expansion is caused by heat and forms a cellular structure that provides the microspheres with mechanical properties whilst reducing the weight of the material. For instance, expandable microspheres may expand to volume expansion of as much as 60 times their original size. This excellent performance makes it a key player in the application such as light-weight construction materials and automotive industry. In addition, it is very environmentally friendly to use such expandable microspheres, they will reduce material consumption raw materials, and energy consumption during production to traditional materials, which is also very commendable.

Role in Modern Material Engineering

Compact expandable microspheres are shaping the future of material science with the exciting opportunities in a large range of sectors. In construction, they also provide for more efficient, longer-lived materials. In automotive, it also creates the possibility of light-weighting vehicle parts with microspheres to make them as much as 20% lighter and produce fuel savings while meeting tight emissions regulations. That trend of lightweighting comes with sustainability, as microspheres use less material. Its potential is still being discovered through continued research and advancements in microsphere technology. Works of universities demonstrate progress of mechanical performances (tensile and thermal) and polymer based materials. As the trend of lightweight and environmental protection in various industries, expandable microspheres is playing ecological and innovative significance in the material industry.

Weight Reduction Without Compromising Strength

Automotive Component Lightweighting

Compact expandable microspheres are now taking a center stage in automotive light-weighting principles by delivering an outstanding compromise between weight reduction and strength retention. They include automotive manufacturers such as Ford and BMW, who use these materials for parts like bumpers and and dashboard panels to reduce vehicle weight considerably while maintaining strength. Evidence suggests that microspheres can reduce weight by as much as 20 per cent, which equals in direct benefits in fuel economy and emissions, according to studies. Regulations in the automotive sector are becoming more and more severe regarding fuel consumption and the reduction of emission and the use of expandable microspheres places itself as an interesting solution. While these advanced new materials enable manufacturers to satisfy regulatory requirements and consumer desires for cleaner vehicles.

High-Strength Construction Materials

In the building industry, the density of materials is revolutionized by MECS that increase strength without adding weight. These microspheres are used in concrete and insulation boards to create building materials with great properties. Projects such as the EcoBlox Building have already made use of microsphere-enhanced materials in these new contexts, creating increased building efficiency and sustainability. Certifications from sources that follow ASTM standards ensure the material is safe and quality. The analyses also show that the conventional materials are significantly inferior to materials containing expandable microspheres in terms of durability and performance. By selecting these smart interior materials, builders can not only meet but can surpass sustainability requirements for today’s buildings that are durable and energy efficient while being kind to the environment.

Enhanced Performance in Coatings and Foams

Flexibility Improvements in Industrial Coatings

Expandable microsphe res are indispensable for improving both flexibility and impact resistance of industrial coatings. By incorporating these microspheres, manufacturers can give coatings the ability to endure extreme conditions, like chemical exposure and extreme heat. Automotive and construction are the best examples of such industries where longer the life and performance of the coatings better is the safety & efficiency of the vehicles and structures. For example, one industry report indicated that the addition of microspheres to coatings offers 15% greater wear performance than that of unmodified coatings. When applied, microspheres mixed into the coating material expand upon heating to produce a strong, flexible barrier that sticks better and lasts longer.

Foam Density Optimization Techniques

It is also sound practice to utilize blown microspheres to control the density of the foam product, especially when it is desired to efficiently pack e.g., an insulation or cushioning. Depending on the amount of microspheres added to the foam, the density can be tuned to a desired level for optimization of the thermal and cushioning performance of the product. Some industries, like food packaging, bedding and automotive, benefit greatly from these improvements. For instance, up to 20% of raw material costs in the production of foams can be saved by utilizing expandable microspheres, providing attractive cost benefits. This trade-off between decreasing density and maintaining performance ensures that foam materials are both cost efficient and high performing.

Superior Thermal Insulation Properties

Energy-Efficient Building Solutions

Compact-expandable microspheres are revolutionary in energy-efficient construction and packaging. Those materials offer a cell structure that lowers thermal conductor, as demonstrated in many iconic buildings in the name of energy efficiency. For example, construction buildings that incorporate insulation that has been augmented with microspheres have saved up to 30% in energy costs by reducing heat loss. The long term gains are huge — lower energy bills and a smaller carbon footprint due to reduced dependence on the heating and cooling. Such is in perfect harmony with the increasing demand for environmentally friendly construction materials focusing on a balance between economic and ecological performance through the use of advanced thermal insulation technologies.

Insulation Performance in Extreme Conditions

ISO marks are best used in cold temperature and weather conditions. The excellent insulation properties of the material makes it weather-independent, hot or cold. Case studies have showed that microsphere insulation have been working successfully in extreme weather conditions confirming their durability. Also, it has been demonstrated that these materials are superior insulation material as compared to any traditional insulation materials in terms of thermal resistance. This is important in establishing a stable indoor climate and improving energy efficiency particularly in adverse environments where traditional materials may not function. Thermal resistance ratings are an indication of how well microsphere insulation holds up over time, regardless of climate.

Surface Finish Enhancement Applications

Smooth Texture Development in Consumer Products

The system of the unitized expandable microsphere is changing the surface property of the consumer goods into various forms of the finish by improving the degree of smoothiness. These microspheres are largely responsible for producing the silky texture in products such as cosmetics and household items. Top of the range cosmetic brands are using this technology to create exciting creams and lotions with silky textures, perfect for the growing demand for luxury textures by the consumer. Because soft texture is in line with consumer demands, products with soft texture receive high satisfaction in market research data. Consumers are focusing on products that not only work, but work beautifully and provide a wonderful tactile experience, which is increasing the demand for novel texture of products.

Matte Finish Advancements in Industrial Design

Using expandable microspheres is the key to obtaining matte, scratch-resistant finishes in industrial design. In industries like automotive and electronics, where non-polluted products are frequently a requirement, these microspheres aid in producing items with a uniform matte finish. For example, matte finish automotive coatings became industry standards because of perceived value (aesthetics) and for functional reasons. Both consumers and designers prefer the matte finish trend according to research. Microspheres are key to fabrication recipes that rely on a great surface finish, good control of appearance and durability yet can't/don't require a high performance resin.

FAQ Section

What are compact expandable microspheres?

Compact expandable microspheres are tiny spherical particles made of a polymer shell containing a gas. They expand when heated, creating a cellular structure that enhances material properties.

How are expandable microspheres beneficial in construction?

In construction, expandable microspheres enhance material strength and efficiency, leading to more durable and sustainable building materials. They reduce weight while maintaining structural integrity.

Why are microspheres used in the automotive industry?

Microspheres reduce the weight of automotive components, leading to improved fuel efficiency and lower emissions, which aligns with industry regulations and consumer demand for greener vehicles.

How do microspheres improve industrial coatings?

Microspheres enhance the flexibility and durability of industrial coatings, ensuring that they remain intact under harsh conditions, thus prolonging the lifespan of the coated products.

Can microspheres contribute to energy efficiency?

Yes, microspheres significantly enhance thermal insulation, reducing heat transfer and saving energy costs, making them suitable for energy-efficient building solutions.