The Growing Demand for Lightweight, Durable Materials

Lightweight materials are becoming increasingly popular in many different sectors, especially automotive and aerospace industries. This trend mainly comes from wanting better fuel economy and cutting down on harmful emissions. When cars get lighter, they burn less gas and produce fewer bad emissions, which helps them pass tough environmental rules while also saving money at the pump. The same principle applies to airplanes too. Airlines love finding ways to make their planes lighter because every pound shaved off means real money saved on fuel costs over time. With both car makers and plane builders pushing forward, there's growing interest in finding materials that manage to be light without sacrificing strength or durability requirements.

The demand for materials that hold up under intense stress and tough environmental conditions has never been higher, which has driven some pretty impressive breakthroughs in material science. Companies across many sectors want stuff that doesn't just survive physical punishment but stands up to rust and temperature extremes too. We're seeing all sorts of new developments now, including things like syntactic foams and those expandable microspheres that combine light weight with serious durability. For manufacturers working on everything from aerospace components to underwater equipment, these materials mean they can keep structures intact while still getting reliable operation even when conditions get rough. The impact extends far beyond just making better products it's actually changing how engineers approach design problems in construction, transportation, and manufacturing industries.

Understanding Foamed Microspheres: Structure and Core Benefits

Composition and Manufacturing of Expandable Microspheres

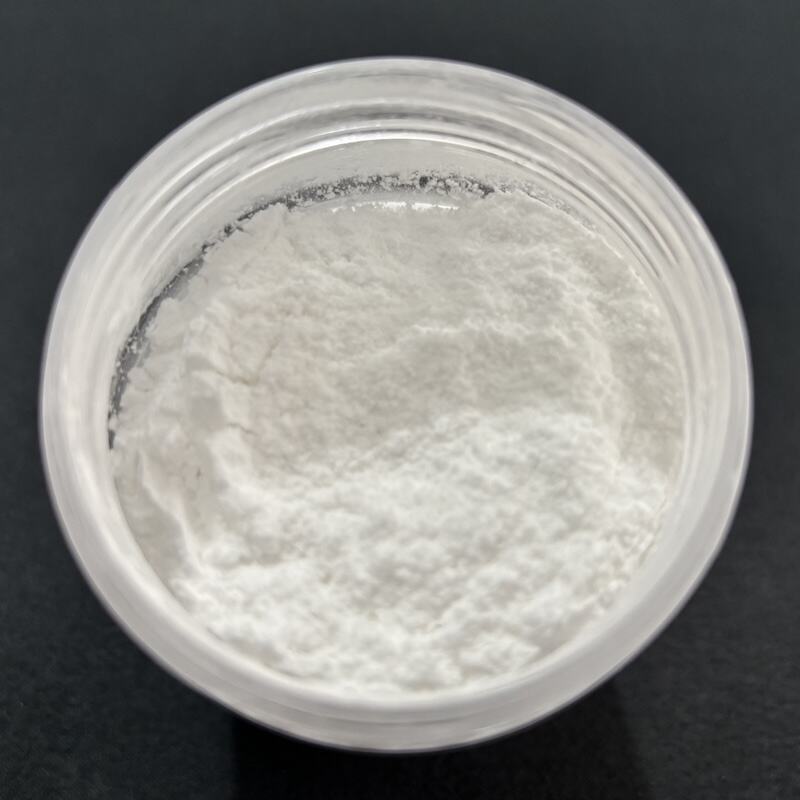

Foamed microspheres, sometimes called expandable ones too, basically consist of polymers that swell up during production to form those hollow little balls inside. What happens is these materials expand when heated, which makes them super light on their feet. That's why they work so well in all sorts of places where weight matters. To make them, manufacturers typically go with methods like suspension polymerization or just let solvents evaporate away. Pretty cool thing about these processes though - they can be tweaked and adjusted quite a bit. So companies end up with microspheres customized exactly for what they need, whether it's insulation material for buildings or components in automotive parts. The adaptability really opens up possibilities across different sectors from construction to aerospace.

Low Density and High Elasticity Properties

Foamed microspheres have this really low density which is why they're becoming popular across various industries looking to cut down product weight while still keeping things sturdy enough. Take cars and household items for instance - lighter components mean better fuel economy and generally improved performance. What's interesting though is how these tiny spheres actually bounce back after getting squished. They absorb shocks pretty well too when subjected to constant pressure over time. That's what makes them so useful in places like car dashboards or protective packaging where stuff needs to withstand impacts but stay flexible at the same time. Manufacturers are starting to realize just how versatile these materials can be in creating products that need both strength and some give.

Thermal and Acoustic Insulation Capabilities

Foamed microspheres work really well for thermal insulation because they contain lots of trapped air inside their tiny spheres. Building contractors love using them in walls and roofs since they help keep homes warmer during winter while cutting down on heating bills. Car manufacturers have started incorporating these materials into dashboards and door panels too, which saves weight without sacrificing comfort. Another neat thing about these microspheres is how they soak up sound waves. When added to composite materials, they significantly cut down on road noise inside vehicles. People who've driven cars with this technology notice a big difference in cabin quietness compared to older models. With both heat control and noise reduction benefits packed into one material, it's no wonder why so many industries are turning to foamed microspheres for everything from construction projects to industrial equipment manufacturing.

Revolutionizing Automotive Design: From Interiors to Performance

Lightweight Interior Panels and Trim Solutions

Adding foamed microspheres to car interiors helps cut down vehicle weight quite a bit, which makes cars run better overall. The stuff is light but still tough enough for making interior panels without sacrificing quality or structural integrity. What's interesting is how these microspheres also create some pretty cool trim options for carmakers looking to spruce up cabin designs while keeping installation simple. Most importantly, the trims hold up well against everyday wear and tear, staying put even when exposed to different temperatures and humidity levels inside vehicles. They manage to combine good looks with practicality something manufacturers really need these days.

Noise-Reducing Coatings Using Foamed Microspheres

Car manufacturers have started using coatings mixed with foamed microspheres to cut down on road noise, making car interiors much quieter than before. The soundproofing effect really matters to drivers who want peace during their commute since it blocks out highway rumble and other outside disturbances. What's interesting is that these same coatings also work wonders for temperature control inside vehicles, keeping them cooler in summer heat without overworking air conditioning systems. While some might question if all this adds unnecessary cost, many automakers see value in combining noise reduction with climate management features, which ultimately improves overall ride quality while potentially saving fuel over time.

Structural Components for Enhanced Fuel Efficiency

Adding foamed microspheres to car parts makes them lighter while still keeping them strong enough for everyday driving conditions. The lighter weight means cars burn less gas at the pump because they don't have to work as hard to move around, yet drivers still get all the protection they need from crashes. Fuel economy has become super important lately with rising gas prices and stricter emissions regulations across the board. Car makers are really getting creative with materials these days. Foamed microspheres offer something special though their air pockets inside the material make them both light and tough. This lets automakers build greener vehicles without sacrificing quality or driver satisfaction, which is exactly what consumers want right now as environmental concerns grow alongside our love for powerful machines.

Transforming Footwear Technology: The Rise of Advanced Midsoles

Midsole Cushioning Systems with Energy Return

Adding foamed microspheres to shoe midsoles is changing the game for sports shoes, giving them better cushioning and bounce back when runners hit the ground. The tiny air pockets inside these spheres absorb shocks much better than traditional materials, so feet don't get as tired after long runs or intense workouts. Comfort levels have jumped quite a bit too, meaning people can keep going longer without feeling sore. We're seeing manufacturers tweak these microsphere formulas all the time now. Some companies are even experimenting with different shapes and sizes to target specific foot areas. This innovation isn't just for pro athletes anymore either regular folks who spend hours on their feet are starting to notice the difference in daily wear.

Customizable Support Through Microsphere Engineering

Foamed microspheres have opened up new possibilities for creating midsoles that match individual athletic requirements. Customization has become essential for manufacturers who want to cater to different activities and foot types across their product lines, which naturally expands their customer base. Brands utilizing these engineered materials can offer shoes with support systems that adjust according to various impact forces during exercise, resulting in better stability and overall performance. What makes this technology stand out is how it balances comfort with proper support structures, something athletes from all backgrounds need when they're pushing themselves physically day after day.

Key Advantages Driving Cross-Industry Adoption

Weight Reduction Without Structural Compromise

Adding foamed microspheres to manufacturing gives companies a real boost when it comes to cutting down on weight without sacrificing how strong the final product is. Think about cars and planes where manufacturers are always looking for ways to make things lighter without making them weaker or less durable. Lighter vehicles burn less fuel, which helps cut down on emissions and saves money over time. Plus, using fewer materials means less waste overall. For businesses, this translates into lower costs since they need less raw material to produce the same amount of goods. Companies that adopt this technology often find themselves ahead of competitors because consumers today expect greener options and better performance from their purchases.

Flexibility Across Material Science Applications

Foamed microspheres have really taken off in material science because they work so well in all sorts of situations beyond what people originally thought possible. We see them popping up everywhere now—from building insulation materials right through to cutting edge electronics manufacturing. What makes these tiny spheres so special is how adaptable they are. Manufacturers can tweak their properties to fit exactly what different industries need. For instance, adding them to wall insulation boosts heat retention while incorporating them into car parts improves crash protection. These little bubbles find their way into everything from DIY home improvement projects to sophisticated medical equipment. That's why many engineers consider them essential building blocks when developing new technologies across various sectors today.

Cost-Efficient Manufacturing Processes

Foamed microspheres really cut down on manufacturing costs, giving businesses a serious edge when looking to save money. When manufacturers tweak how they produce these tiny spheres, they end up using way less raw materials and energy, which means lower bills at the end of the month without sacrificing quality. What's more, with green manufacturing becoming all the rage across different sectors, these little bubbles actually help reduce waste and carbon footprints too. Companies love them because they get both wallet-friendly production and something that looks good on their sustainability reports. The fact that businesses can now go green without breaking the bank explains why so many factories are switching over to this technology lately.

Conclusion: The Expansive Future of Microspheres Technology

Looking ahead, microsphere technology seems to have a bright future, especially since foamed microspheres are becoming increasingly important in new material developments. Industries keep asking for lighter yet stronger materials, and this demand is growing fast in construction, aerospace, and even consumer products markets. Companies want stuff that works well without wasting resources, so foamed microspheres naturally fit into this equation. These tiny spheres can be adapted for so many different purposes, which makes them really valuable for creating sustainable solutions. From insulation materials to composite structures, their ability to meet diverse industry requirements while reducing environmental impact means businesses across sectors will continue relying on them as we move forward.

FAQ Section

What are foamed microspheres?

Foamed microspheres are lightweight, expandable polymer spheres used in various industries for applications requiring reduced weight and enhanced durability.

How do foamed microspheres enhance automotive design?

They contribute to weight reduction in interior panels and offer soundproofing and temperature regulation capabilities, improving vehicle efficiency.

Can foamed microspheres be beneficial in footwear technology?

Yes, they enhance midsoles for better cushioning, energy return, and customizable support, improving athletic footwear performance.

Table of Contents

- The Growing Demand for Lightweight, Durable Materials

- Understanding Foamed Microspheres: Structure and Core Benefits

- Revolutionizing Automotive Design: From Interiors to Performance

- Transforming Footwear Technology: The Rise of Advanced Midsoles

- Key Advantages Driving Cross-Industry Adoption

- Conclusion: The Expansive Future of Microspheres Technology

- FAQ Section