The coatings industry keeps evolving with new innovations aimed at improving performance while cutting costs and becoming greener. One additive making waves lately is expandable microspheres. These tiny particles pack quite a punch when it comes to functionality. They work wonders in all sorts of coating applications, from simple decorative paints used on walls to complex industrial coatings that need to stand up to harsh conditions. What makes them so special? Well, they offer properties that just aren't possible with traditional materials alone.

But what exactly are expandable microspheres, and why are formulators increasingly incorporating them into their coating systems? Understanding how these materials function and the advantages they bring can help manufacturers optimize product performance and unlock cost efficiencies.

What Are Expandable Microspheres?

Basic Composition and Working Principle

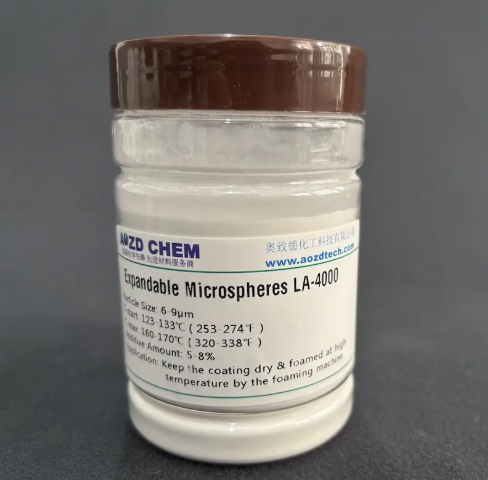

Expandable microspheres consist of tiny round particles with a thermoplastic outer layer surrounding some kind of blowing agent, often something like a low boiling point hydrocarbon. Heat gets applied and suddenly things change - the outer shell starts to soften while whatever's inside begins expanding rapidly. The result? These little spheres can grow their volume anywhere from 50 to even 80 times what they started as! After this dramatic growth spurt, everything cools down again and hardens into place, locking all that gas within creating these strong yet empty structures that look like miniature balloons frozen mid-inflation.

This expansion process is irreversible and provides coatings with a lightweight structure, enhanced texture, and numerous functional benefits. Typically, the unexpanded microspheres range from 10 to 20 microns in diameter, and upon expansion, they can grow to 40 to 80 microns.

Unique Physical Properties

The defining trait of expandable microspheres is their low density post-expansion. The hollow, closed-cell structure not only reduces material weight but also contributes to thermal insulation, sound dampening, and increased elasticity. These characteristics make them ideal for coatings that require high performance without compromising formulation stability.

Their small size and inert chemical makeup also allow for easy dispersion in aqueous and solvent-based systems, adding further flexibility to their use.

Benefits of Using Expandable Microspheres in Coatings

Weight Reduction and Material Efficiency

One of the most prominent advantages of using expandable microspheres is their ability to reduce the overall density of the coating film. By introducing microspheres into the formulation, manufacturers can achieve a higher film build with less material, leading to cost savings and lighter weight products.

In automotive and aerospace applications, for instance, reducing weight directly translates to improved fuel efficiency and lower emissions. Even in decorative paints, a lighter product can be easier to apply and transport.

Surface Texture and Matte Finishing

Many industries rely on expandable microspheres to tweak how coatings feel and look on surfaces. When these tiny spheres expand during application, they create just enough texture while controlling how light reflects off the surface. The end result? A nice smooth matte or eggshell finish that doesn't glare too much. Interior painters love this effect for walls because it gives rooms a warmer, more inviting atmosphere without all that shiny stuff bouncing around. Specialty paint manufacturers have found similar benefits in products meant for furniture finishes and automotive touch-ups where people want something that looks good but isn't blindingly bright either.

Moreover, microspheres can improve hiding power by increasing the scattering of light, enhancing the paint’s visual depth and coverage.

Functional Enhancements Across Industries

Thermal and Acoustic Insulation

Due to their hollow, closed-cell structure, expanded microspheres naturally insulate against heat and sound. When added to coatings for construction, appliances, or even textiles, they help reduce thermal conductivity and dampen noise.

This makes them highly valuable in building materials and appliance coatings, where energy efficiency and noise reduction are critical selling points. Additionally, their inclusion can improve fire retardancy in specialized formulations.

Impact Resistance and Elasticity

Coatings formulated with expandable microspheres often exhibit better resistance to cracking and chipping. As the microspheres compress and rebound under pressure, they help absorb energy and distribute stress across the surface.

This property is particularly beneficial in protective coatings, industrial flooring, or flexible membranes, where durability and resistance to physical wear are essential.

Formulation Considerations

Compatibility with Resin Systems

Expandable microspheres are generally compatible with a broad range of resin systems, including acrylics, polyurethanes, epoxies, and alkyds. However, it’s crucial to ensure proper dispersion to prevent clumping or uneven expansion.

Some microspheres are pre-expanded for ease of use, while others are designed to expand during curing or baking stages. Choosing the right type depends on the application process and curing temperature.

Dosage and Processing Guidelines

Typical usage levels for expandable microspheres in coatings range from 0.5% to 5% by weight, depending on the desired effect. Overuse can lead to issues such as foaming, poor adhesion, or reduced gloss, so it’s important to balance loading with other formulation components.

Processing conditions, particularly temperature, play a key role in activating expansion. For heat-cured coatings, accurate temperature control is essential to ensure consistent performance.

Sustainability and Environmental Impact

VOC Reduction and Lightweight Packaging

Expandable microspheres can help formulators reduce the need for solvent-based viscosity modifiers, contributing to lower VOC content. Additionally, the reduced density of the final product enables more efficient packaging and transport, minimizing environmental impact across the supply chain.

Lighter packaging also means lower emissions during shipping and improved handling safety for end-users.

Safer, Non-Toxic Composition

Most expandable microspheres used in coatings are free of harmful heavy metals or toxic additives. Their inert nature makes them suitable for use in consumer-facing products, including children’s furniture, toys, and household items.

With growing regulatory pressure to adopt safer, greener chemicals, microspheres provide an effective way to meet compliance while maintaining high performance.

Real-World Applications

Decorative and Architectural Paints

Expandable microspheres are widely used in decorative wall paints to enhance texture, improve coverage, and reduce gloss. They also contribute to scrub resistance, helping walls withstand repeated cleaning.

In architectural coatings, microspheres are valued for providing thermal and sound insulation, making them ideal for homes, schools, and hospitals.

Industrial and Protective Coatings

In industrial settings, coatings enhanced with microspheres are applied to machinery, pipes, tanks, and structural steel to add durability and reduce weight. These coatings often benefit from improved impact resistance and temperature stability.

Specialty coatings for marine, mining, or oilfield applications also leverage the insulating and elastic qualities of microspheres to prolong service life in harsh environments.

FAQ

Are expandable microspheres safe for consumer applications?

Yes, most commercially available microspheres are non-toxic and comply with safety regulations, making them suitable for household and decorative uses.

At what temperature do expandable microspheres activate?

Activation typically begins at 100–150°C, depending on the formulation. Specific grades can be tailored for different curing processes.

Can microspheres be used in water-based coatings?

Absolutely. Many microspheres are designed for easy dispersion in both water-based and solvent-based systems.

Do expandable microspheres affect coating color?

They can slightly influence opacity and brightness, but usually do not significantly alter color when used at recommended dosages.