Cad iad na Sferaí Meicre <br> agus conas a úsáidtear iad ginearálta?

Sferaí Meicre <br> is iad siad páirceanna beaga nuálacha a thug athrú ar mhóran eagraíochtaí trí réitigh éagsúla, éasca agus costas-éifeachtacha a sholáthar. Tá na spéiríní maithe seo i gcomhcheangal le hairíonna uqucha—méid beag, leathnúchas agus staidiúlacht struchtúrtha—agus mar sin tá luach acu i bhfeidhmchláir atá i gclúdach plúchanna agus tóir pliastach go dtí tograíocht agus éadach. Tá tuiscint ar cad sferaí Meicre <br> is iad agus conas a oibríonn siad is eis a bheith ina bhfeidhm iad a bheith in ann a mbuntáistí a úsáid. Soláthraíonn an treoir seo leagan amach ar a struchtúr, meicníocht agus úsáidí ginearálta, ag tabhairt faoi deara cén fáth a bhfuil siad ina mholtaíocht do rogha i leithéidíochtaí tháirgiúla nua-aimseartha.

Cad É Microsphéireacha Leasaithe?

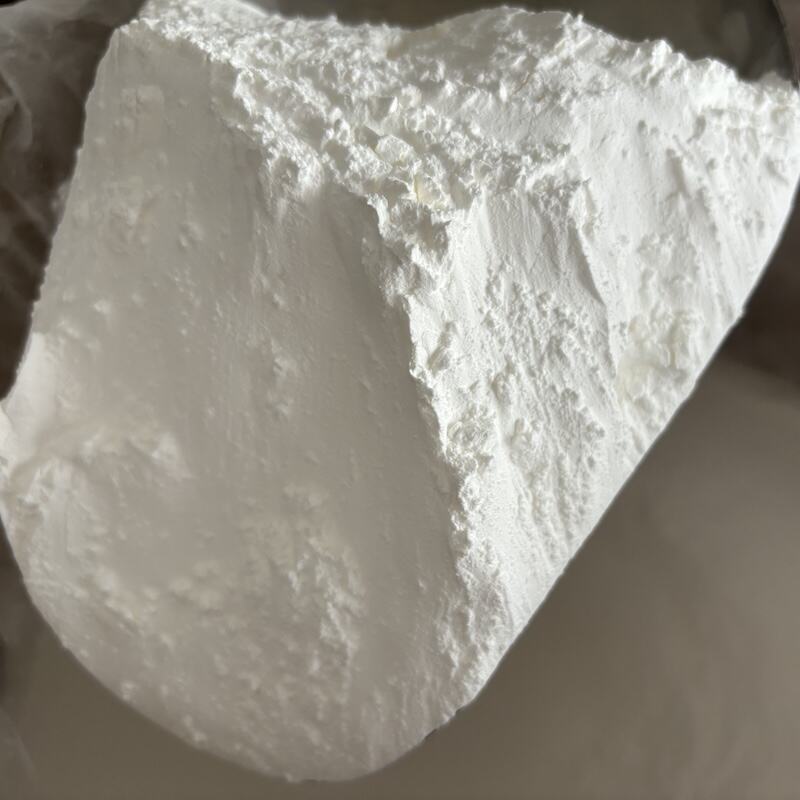

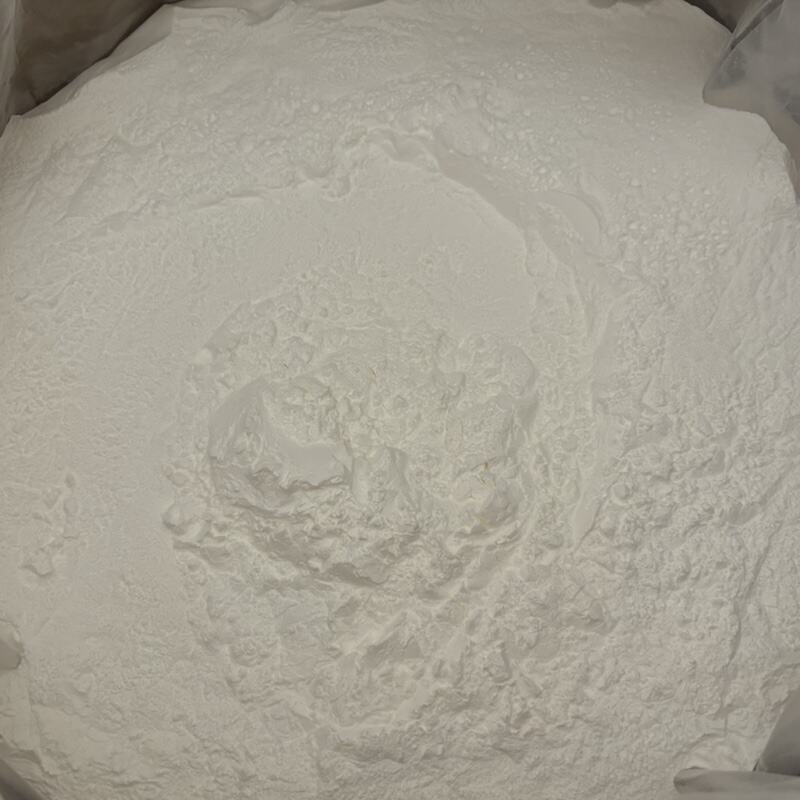

Is micreisféaranna leusaithe é micreisféaranna beaga, folúsachtaí a bhfuil dhá phríomhchuid acu: croíneán polaiméar éagóra nó snaofa agus core a líonadh le leacht voladach (go minic hiocairbhuin nó isopentáin). Is iad seo 5–50 micreamhaidir i ndeireadh roimh leusú, thart ar an méid sin a bheith i ngráin bhreac bhfine. Is dírnithe éadroim nó acrilonitríl, nó acetát vínil a dhéanfar an croíneán polaiméar go hiondúil as, roghnaithe as a bheith in ann síorú agus sreabhadh le linn an leusaithe. Is substainte le pointe boltais íseil é an leacht sa chroí a aillfidh nuair a bheith teocht air, ag cruthú brú istigh sa chroíneán.

Ia staid neamhleathnaithe, is éard is féidir leis na micreisféaranna leathnaitheach ná púdar éasca a rith, éasca a luascadh leh rudaí eile cosúil le haghaidh réasúin, pliastach, nó lúithigh. Nuair a bheidh teocht air (de ghnáth idir 80–200°C, ag brath ar an bhfoirmleáil), déanann an t-uisce phríomhthurna a athrú go gás, agus é ag leathnú an chosáin go 5–30 huaire a méid bunaidh. Nuair a bheidh sé leathnaithe, an cosán téighidh síos agus é a chríochdú, agus é a choinneáil na micreisféaranna i bpéireacht nua, cruth móra—spéiríní folmha, éadomhla, a chaillfidh siad an t-integraíocht struchtúrtha. Is é an meicníocht leathnaithe seo aiceanta é seo a chumhachtú expandable microspheres a chur iolraigh, laghdú ar an gciúlacht, agus feabhas ar airíonna ábhair gan aon gá le haghaidh neart a chompromáid.

Conas a oibríonn microsphéaraí leasaithe?

Bonnann an fheidhmíocht aige ar mhicreisféaranna leathnaitheach ar phróiseas leathnaithe teasa simplí ach éifeachtach:

- Taisce agus Luascadh ia staid neamhleathnaithe, tá na micreisféaranna leathnaitheach seasta ag teocht an tseomra. Is féidir iad a luascadh isteach i leachtanna, i pastai, nó i solaidí (cosúil le ráta pliastach nó foirmleáil lúithigh) gan aon imhoibriú, ag cinntiú caomhnaíocht chothrom.

- Teas agus Leathadh : Nuair a theitear iad go dtí a dtémpéartúir ghníomhachta, déanann an t-uachtar leictreacha túbach páirteanna, ag giniúint brú istigh sa gcoire liathróid. Síleann an t-athrú nuair a leathnaíonn an gháis, ag méadú go mórardhach ar thomhas na liathróide beaga.

- Fionúint agus Stabilíocht : Tar éis díreachadh an méid is mian leis an méid, fuarófar an t-ábhar, agus daoródh an t-athrú liathróid. Cuireann sé seo i bhfeidhm an t-athrú leathaithe i bpéireacht a dtírdhreach nua, ag cruthú struchtúir hólmha, folamh a fhanann seasmhach faoi choinníollacha gnáthúla.

- Comhtháthú sa Táirge Deiridh : Téann na liathróidí leathaithe a bheith ina cuid den mhatraic shamhail, ag cur leis na hairíonna cosúil le laghdú ar an gceannaireacht, feabhas ar an insileáil, nó méadú ar an mbeartas, ag brath ar an úsáid.

Ní féidir an phróiseas seo a aisiomh—nuair a bheith leathaithe, ní féidir leis na liathróidí filleadh ar a dtomhas bunaidh, ag cinntiú go fanann na hairíonna matraice seasmhach thar an t-am.

Airíonna Crucial na Liathróidí Leathaithe

Tá cáil na micreisféar éagsúla ar siúl ón gcuid éagsúil airí a bhfuil acu, rud a dhéanann iad iolrúchánach do úsáid éagsúla:

- Gaolmhara : Tá 70–90% aer againn i micreisféar éagsúla de réir tomhais, ag laghdú go mór ar an gceannra an t-ábhar a cuireadh isteach ann. Tá sé seo rannpháirtí do iarratais ina bhfuil laghdú ar an mbáisteachacht ina phríomhchuspóir, cosúil le páirtíthe gluaisteáin nó bainistíocht.

- Insliú teirmeach : Tráth an struchtúir bhfolctha, tá an aer cosc leis an ngéim a chosc a chur chun cinn. Déantar an t-ábhar a bhfuil micreisféar éagsúla iontu níos fearr a bheith ina insiléadóirí, úsáidtear i dtógáil nó súraclóidí teochracha.

- Neart Meicnicigh : Mar gheall ar an mbéim éadrom, cuireann micreisféar éagsúla tacaíocht struchtúrtha leis. Déantar iad a sháthadh go cothromach san ábhar, ag feabhsú ar an gcosc éadomhachta agus an méadúchán.

- Laghdú Íseal : Ar an drochuair roinnt agéantí éag, méadaíonn micreisféar éagsúla go cothromach agus laghdaíonn siad go minic i ndiaidh an fhuaite a bheith ag teacht, ag cinntiú a bheith seasmhach de réir tomhais san táirge deiridh.

- Cobhsaíocht Cheimiceach : Tírionn an t-iadail plóiméara i bhfianaise, i bputóigí, agus i gcaoi UV, rud a dhéanann iad i gceart do choinníollacha tromchúiseacha.

- Cuideachta Sosa : Is maith leo comhshó le raon leathan tairiscintí, lena n-áirítear plóiméir, rúbair, binnil, agus lúithigh, gan riachtanas le haghaidh tionscail chun iad a chur isteach.

Úsáidí Coitianta na mBileogán Leathnaitheacha

Tá úsáid fhorleathan ag bileogáin leathnaitheacha i roinnt tionscal, buíochas do a gcumas chun airíonna tairiscintí a fheabhsú ag an am céanna agus costais a laghdú. Seo iad a n-úsáidí is coitianta:

1. Cuirp agus bróga

I lúithigh agus in ainmhíochtaí, feabhsaíonn bileogáin leathnaitheacha an téacs, laghdaíonn siad an tseiseamh, agus feabhsaíonn siad an t-inneall:

- Lúithigh Téacsaithe : Nuair a chuirtear i bhformholtú na n-ainmhíochtaí, leathnaíonn na bileogáin leathnaitheacha le during (teoite ag próiseas tethúcháin), ag cruthú téacs ardaithe, matúil nó samhailteach. Tá sé seo coitianta i lúithigh dearcraitheacha do chosa, do chosúlacht, nó do thagairtí heachtracha, áit a bhfuil críochnaitheach teagtha de dhíth.

- Léine Léite : Trí chur na leathanach trom in ionad na micreisféar éagsaithe, táirgeann na monlaíotóirí pinn luichte a bhfuil sé éascaí a chur ar fáil agus a laghdaíonn costais seoltaíochta.

- Cochrúidí Lethroí : Cuirfidh an struchtúr bhfolctha na micreisféar leatha teocht a chothú i bpinn a úsáidtear i dtithe nó i réimsí tionsclaíochta, ag cabhrú le teocht nó fuaracht a chothú.

- Cuirtheacha I bhfoghmhairiú : I gcochrúidí peann, cruthaíonn micreisféar éagsaithe scamaill shéimh, inaithnítear a bhuailfidh, ag laghdú ar bhriste agus ag feabhsú cosaint ó chlathú.

2. Plastach agus Comhábhair

Tugann plastach agus comhábhair mhórbhuíochas mór ó mhicreisféar éagsaithe, go háirithe i laghdú meáchain agus i bhfeabhsú struchtúrtha:

- Plastach Éadrom : Tugann cur micreisféar éagsaithe san adhmhas plastach (mar shampla, polipropaléin, polaitheilín) laghdú ar dhlúsacht suas go 40% agus neartacht a choimeád. Úsáidtear é seo go forleathan i gcríocha gluaisteáin (stiúirbhoird, pannaí dorcha), ag laghdú meáchain an ghluaisteáin agus ag feabhsú éifeachtúlachta na gcuairte.

- Plastach Bhóthailte : Ar leithéidíoch le haghawairí foamaithe traidisiúnta, cruthaíonn micreisféiríní leathnaithe struchtúir foamhacha cealla cothrom. Is é seo an t-ábhar iomchuí do mheic an bholgáil, áit a mbreosnaíonn seasmhacht sheachadach nithe briste.

- Máteríláí Acmhainneacha : I gcomhpháipéir (mar shampla, dearcrua nó crua carbon), laghdaíonn micreisféiríní leathnaithe meáchan gan iomlánacht a chailleadh, rud a dhéanann iad tábhachtach i gcomhpháirtí aeráid, curadóireacht spóirt (roithlí, cliathanna ceann) agus lámhaí turbiní aerach.

- filimeanna Priontála 3T : Agamh i ngearrthóirí priontála 3T, cruthaíonn micreisféiríní leathnaithe priontóil éadrom, porcálacha le haghaidh seachadtaíocht fearasctha, úsáidtear do phróitéapa agus páirteanna saincheaptha.

3. Gluail agus Sreabhláithreoirí

Ocáidíonn micreisféiríní leathnaithe feidhmíocht gluail agus sreabhláithreoirí trí fheidhmchlú a fheabhsú, meáchan a laghdú agus clúdach a mhéadú:

- Gluail Shleamhnaí : I ngluail do ghearradh leatháin le rátaí leathnaithe éagsúla (mar shampla, iarann agus plastaic), oibríonn micreisféiríní leathnaithe mar bhuffear, ag iarraidh stress agus ag préabadh craicbhí.

- Sreabhláithreoirí Líonta Líonacha : Nuair a théitear iad, méadaíonn na micreisféar gus breisí a líonadh, ag cruthú sreanga teagtha, insilíochta i dtógáil (frámaí fuinneoige, sciatháin) nó i dtionscail oithreachais (nóidí, sioncróidí).

- Sealantí Éadroma : Trí lúú a dhéanamh ar dhlúsacht, déanann micreisféar leathnaithe sealantí éasier a chur i bhfeidhm agus lúann siad an t-iomaíocht ar struchtúir, soiléir i sealtántaí aeirspáis nó muirí.

4. Maitéirial Tógála

: I dtógáil, cuireann micreisféar leathnaithe le héifeachtúlacht fuinnimh, dearadh éadrom agus foréigeanacht:

- Concraid Insilíoch : Nuair a chuirtear i luchtanna concraid, déanann micreisféar leathnaithe pocaí aer a chruthú a fheabhsaíonn insilíocht teochta, ag laghdú caillteachta teochta i mbailte. Laghdaíonn siad meáchan an choncraid chomh maith, ag éascaíocht ar aistriú agus suiteáil.

- Ballta Tógála agus Plástar : I gcomhdhúnta ballta agus plástar, cuireann na micreisféar le h-oibríocht, laghdaíonn siad shrinkage, agus cuireann siad insilíocht leis. Déanann sé seo deichreanna ghlana a bhíos níos lú éadrom go corrach.

- Maitéirialí Ais : I gclúdach vinil nó lamináid, cuimsíonn na micreisféirí leathnaithe cothabháil, ag déanamh na gconaí níos suíochána faoin mbóthar agus feabhsú insilte huaigh fuaim.

5. Téacsíl agus Clúid

Úsáidtear micreisféirí leathnaithe chun airíonna téacsíl a athrú, ag cur téacsúir, insilte agus éadomhanacht leis:

- Clúid Théarmach : Sna clúid (mar éadroma geimhreadh, bainneáin), cuimsítear nó cuimsítear na micreisféirí leathnaithe aer, ag feabhsú insilte théarmach gan méadú ar an méid a thagann isteach.

- Téacsíl Téacsúrtha : I éadaí nó téacsíl tighe, leathnaíonn na micreisféirí le linn an phróisiséil chun patrúin ardaithe nó cosúlacht bog, plúiseach a chruthú, tá cáil orthu i léineacha seomra nó croonadh suíocháin.

- Éadaí éadrom : Trí lathú a laghdú ar densacht an chlúide, cuideann na micreisféirí leathnaithe le haghaidh cruthú éadaí éadomh, ina bhfuil an-droim agus a choinneálann siad teocht, i bhfad is fearr do chuidiú seoltaíochta.

6. Pácaireacht

Tá pácaireacht ina hiarraidh mhór le haghaidh micreisféirí leathnaithe, áit a mbíonn a gcuid éadomhanacht agus cothabháil ina mbuailfidh siad amach:

- Pacáistiú cosanta : Cruthaíonn micilíonta leathanna i bpacáiste foamhaireachtshúile amhú ag cosc do leictreonach, glassa, agus nitheanna briste a chosú le linn an tarchuir.

- Comhaidheanna Éadroma : Cuireadh isteach i gcaipéisí pacáiste plastaigh, laghdaíonn siad an tseine, ag laghdú ar an gcostas tarchuir agus ag feabhsú an athraitheachta trí níos lú talmhaíochta a úsáid.

- Pacáiste Teo-insliotúil : Do sheoltaíocht bia nó pacáisteanna feirmaceutach, cuireann micilíonta teo-insliotúcháin, ag coimeádadh ar an ngnáth teocht nó fliuch ar feadh tréimhsí níos faide.

Fachtóirí Chun a Chinntiú Nuair a Bhíonn ag Úsáid Micilíonta Leathnaitheacha

Chun na breithníní a bhaint as micilíonta leathnaitheacha a uasmhéadú, déan cinnte de na fachtóirí seo a leanas:

- Teocht Ghníomhaíochta : Gníomhaíonn foráilíochtanna éagsúla ag teochtaí éagsúla (80–200°C). Roghnaigh micilíonta le teocht ghníomhaíochta comhoiriúnach le do thiontaitheoirí agus do chábhair (mar shampla, seomraíonn uait theochtaí ard do phlastaí íogair teochtaí).

- Cúlra Leathnú : Dépendann an méid leathnú (5–30x) ar chineál na micreisféar. Laghdaíonn comhráidí níos airge an domhanacht ach b’fhéidir go laghdaíonn siad an t-ádhais – cothromaigh leathnú le híocfhórsaíocht.

- Comhoiriúnacht : Déan cinnte go mísleann na micreisféar go maith le do mholta bunaidh (mar shampla, plastach, lúithigh). Déan tástáil chun cluimhpeáil nó imscríobhaidh ceimiceacha a aithint sula n-úsáidfidh tú iad ar mhéid mór.

- Méid Páirticil : Cruthaíonn micreisféar níos lú (5–20μm) críocha níos gléibhre, agus is iad na micreisféar níos mó (20–50μm) a chuireann níos mó téacsúir leo. Roghnaigh bunaithe ar chomhdhéant an achrainn is mian leat.

FAQ

An bhfuil microsphéaraí leasaithe bródúla don fhorleathan?

Tá micreisféar leathnaitheaimh nua-aimseartha déanta as pailmirí neamh-ontacha agus leachtaí voltáilte nach seascaidh siad ábhair harmful ag leathnú. Laghdaíonn siad freisin úsáid na hairgid, ag tacú le haghaidh comhshaoil trí laghdú ar charachtar agus fuinnimh a úsáidtear i réimsí eolais agus saothrúcháin.

An féidir micreisféar leathnaitheach a athúsáid tar éis leathnú?

Níl, ní féidir é a thuilleadh. Nuair a thétear iad agus iad leathnaithe, cruaíonn an cúrca polymer, agus ní féidir na micre-sféaracha a laghdú ar ais go dtí an méid is ea iad. Tá siad deartha do úsáid amháin i bpócairí monaróla.

Cad a tharlaíonn má théitear na micre-sféaracha a fhéadfaidh tuilleadh?

Is féidir leis an téiteacht aill a bheith agus an cúrca polymer a bhuailt, ag cosc ort go leathnú go soiléir nó agus a bheith ag titim. Cuir i gcrích i gcónaí réimse na téiteachta a gholraíonn an fabhróir chun cinneadh a bheith againn ar an gceartas is fearr.

An bhfuil aon éifeacht ag micre-sféaracha a fhéadfaidh tuilleadh ar dath na gcearcaill?

Níl, is geal nó bán iad micre-sféaracha a fhéadfaidh tuilleadh mar gheall ar a n-dath, agus ní athraíonn siad dath an tseoltaigh bunaidh. Is féidir iad a úsáid le comhaidh dathaithe, plástach, nó éadaí gan aon ghealú nó caill ar dath.

Conas a stóráiltear micre-sféaracha a fhéadfaidh tuilleadh?

Stóraigh iad i gcomhartha fionnuil, tirim ag teocht seomra (faoin 30°C) chun éalú a bheith againn ó thiontú go luath. Coinnigh iad dúnta chun coinneáil uisce a bheith ag imeacht, is féidir leis sin a stabhtacht a bheith ag athrú.

Clár na nÁbhar

-

Cad iad na Sferaí Meicre

agus conas a úsáidtear iad ginearálta? - Cad É Microsphéireacha Leasaithe?

- Conas a oibríonn microsphéaraí leasaithe?

- Airíonna Crucial na Liathróidí Leathaithe

- Úsáidí Coitianta na mBileogán Leathnaitheacha

- Fachtóirí Chun a Chinntiú Nuair a Bhíonn ag Úsáid Micilíonta Leathnaitheacha

-

FAQ

- An bhfuil microsphéaraí leasaithe bródúla don fhorleathan?

- An féidir micreisféar leathnaitheach a athúsáid tar éis leathnú?

- Cad a tharlaíonn má théitear na micre-sféaracha a fhéadfaidh tuilleadh?

- An bhfuil aon éifeacht ag micre-sféaracha a fhéadfaidh tuilleadh ar dath na gcearcaill?

- Conas a stóráiltear micre-sféaracha a fhéadfaidh tuilleadh?