कॉम्पैक्ट का परिचय सिलिकॉन इमल्शन समाधान

कॉम्पैक्ट सिलिकॉन एमल्शन क्या हैं?

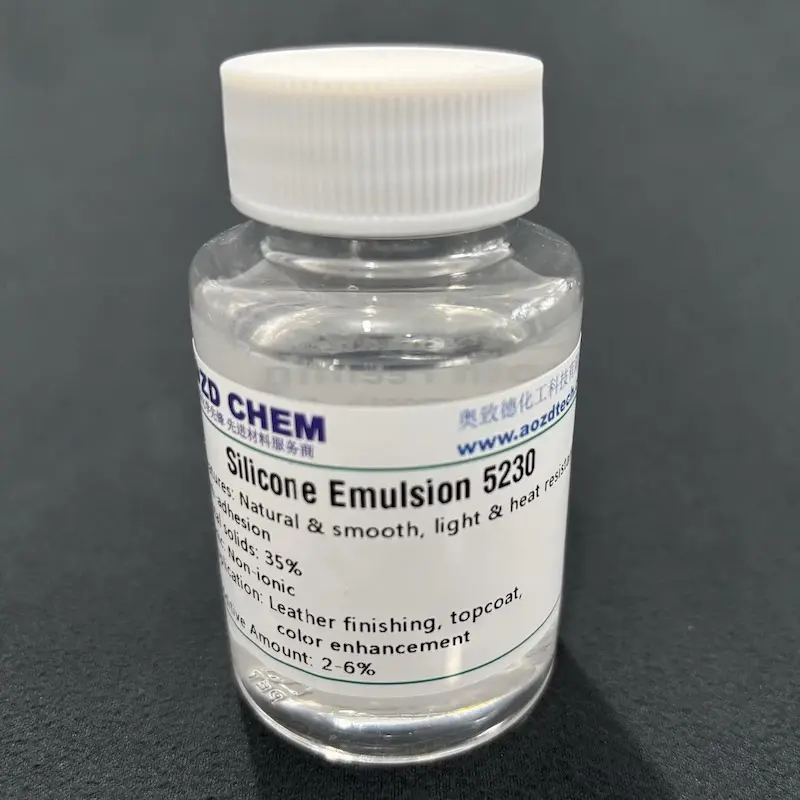

संपीड़ित सिलिकॉन इमल्शन मूल रूप से सिलिकॉन तेलों को पानी के साथ मिलाया जाता है, जो आमतौर पर सर्फैक्टेंट्स द्वारा एक साथ बनाए रखे जाते हैं ताकि वे आसानी से अलग न हों। इन मिश्रणों को खास बनाता है उनका बहुत कम सतही तनाव और सतहों पर फैलने की उत्कृष्ट क्षमता। इन गुणों के कारण निर्माता उन्हें कई उद्योगों में उपयोग करना पसंद करते हैं। विभिन्न सूत्रों में मिलाए जाने पर वे बिना किसी समस्या के बहुत अच्छा काम करते हैं। सही ढंग से चिपकने वाली कार की पेंट से लेकर त्वचा में तेजी से सोख लेने वाली लोशन तक, यहां तक कि उन निर्माण सामग्रियों में जहां स्थिरता बहुत महत्वपूर्ण होती है, इन इमल्शनों का उपयोग हर जगह देखा जाता है क्योंकि उनकी लचीलापन के बराबर कुछ नहीं है। कठिन परिस्थितियों में विश्वसनीय प्रदर्शन की तलाश करने वाली कंपनियां लगातार कॉम्पैक्ट सिलिकॉन इमल्शन की ओर रुख करती हैं।

मुख्य घटक और सूत्रण

सिलिकॉन पॉलिमर, स्थायीकारकों और पानी को मिलाते समय विस्तार से ध्यान देने की आवश्यकता होती है ताकि कॉम्पैक्ट सिलिकॉन इमल्शन बनाया जा सके। इन सामग्रियों के बीच सही अनुपात तय करना निर्धारित करता है कि अंतिम उत्पाद विभिन्न उद्योगों में कितना प्रभावी रहेगा। उदाहरण के लिए, वस्त्र निर्माताओं को एक प्रकार की स्थिरता की आवश्यकता होती है, जबकि कोटिंग अनुप्रयोगों के लिए कुछ अलग ही आवश्यकता होती है। योजक इसमें अन्य घटक भी महत्वपूर्ण भूमिका निभाते हैं। कुछ मानक घनत्व को समायोजित करने में सहायता करते हैं, कुछ शेल्फ जीवन में सुधार करते हैं, और कुछ निश्चित करते हैं कि निर्माण प्रक्रियाओं के दौरान अन्य सामग्रियों के साथ इमल्शन ठीक से काम करे। इस जटिल संतुलन के कारण, कई कंपनियां सूत्रों को सही ढंग से तैयार करने के लिए अनुसंधान में भारी निवेश करती हैं। ये अनुकूलित मिश्रण फिर कपड़ों को बेहतर स्पर्श गुण देने वाले फैब्रिक उपचारों से लेकर धातु की सतहों पर अधिक समय तक चलने वाली सुरक्षात्मक कोटिंग्स तक हर चीज में उपयोग होते हैं।

मुख्य उद्योगी और व्यापारिक उपयोग

कॉम्पैक्ट सिलिकॉन इमल्शन विभिन्न उद्योगों में व्यापक रूप से उपयोग में आते हैं। कारों के लिए, ये पदार्थ कोटिंग्स और स्नेहकों में बहुत अच्छा काम करते हैं, जो पेंट जॉब्स की रक्षा करने और धातु के हिस्सों को जल्दी पहनने से रोकने में मदद करते हैं। वस्त्र निर्माता कपड़ों में इन्हें त्वचा के संपर्क में नरम महसूस कराने और कुछ पानी प्रतिकारक गुण जोड़ने के लिए डालते हैं। लोशन और मेकअप जैसी व्यक्तिगत देखभाल वस्तुओं के मामले में, कंपनियां इन इमल्शनों पर भरोसा करती हैं क्योंकि ये उत्पादों को वह चिकनाहट प्रदान करते हैं जो लोगों को पसंद है और सूत्रों को अलग हुए बिना लंबे समय तक स्थिर रखने में मदद करते हैं। निर्माण श्रमिकों को भी नहीं छोड़ा गया है क्योंकि निर्माता इमारतों के सीलेंट और वॉटरप्रूफिंग उपचारों में इनका उपयोग करते हैं। मूल रूप से, जहां भी किसी चीज़ को स्थायी और लचीला बनाने की आवश्यकता होती है, ऐसा लगभग निश्चित है कि कोई न कोई कॉम्पैक्ट सिलिकॉन इमल्शन का उपयोग कर रहा है।

बढ़ी हुई सतह सुरक्षा क्षमता

अधिक दृढ़ कोटिंग्स के लिए उत्कृष्ट पानी की प्रतिरोधकता

कॉम्पैक्ट सिलिकॉन इमल्शन इसलिए खास हैं क्योंकि ये पानी के प्रतिरोध के लिए जाने जाते हैं, जिसके कारण विभिन्न सामग्रियों पर कोटिंग्स की स्थायित्व में ये बहुत बड़ी भूमिका निभाते हैं। पानी को रोकने की क्षमता के कारण कोटिंग का जीवनकाल काफी बढ़ जाता है, जिसका मतलब है कि इमारतों और संरचनाओं को लगातार मरम्मत या पुनः कोटिंग की आवश्यकता नहीं होती। शोध से पता चलता है कि जब सतहों पर इन इमल्शन्स के साथ उपचार किया जाता है, तो वे सामान्य कोटिंग्स की तुलना में काफी कम नमी को अंदर आने देते हैं। यह तटीय क्षेत्रों या भारी वर्षा वाले क्षेत्रों जैसे स्थानों में बहुत महत्वपूर्ण है, जहां मौसम का अधिक प्रभाव पड़ता है। निर्माताओं ने परीक्षण के माध्यम से पाया है कि इस कम नमी के प्रवेश से कोटिंग्स में समय के साथ बेहतर प्रतिरोधकता आती है, जिससे वे लंबे समय में अधिक स्थायी और लागत प्रभावी बन जाते हैं।

यूवी सुरक्षा लंबे समय तक सामग्री की पूर्णता के लिए

कॉम्पैक्ट सिलिकॉन इमल्शन के पास सामग्री को पराबैंगनी क्षति से सुरक्षित करने के मामले में बहुत महत्वपूर्ण क्षमता होती है, जिसके कारण बाहर उपयोग की जाने वाली किसी भी चीज़ के लिए यह आवश्यक बन जाता है। ये इमल्शन सूर्य के संपर्क में आने से उम्र बढ़ने पर सामग्री के टूटने और रंग उड़ जाने से रोकते हैं, इसलिए जिस चीज़ पर यह लेपित किया जाता है वह काफी लंबे समय तक अपनी स्थिति में बनी रहती है। अध्ययनों से पता चलता है कि सिलिकॉन आधारित लेप वास्तव में सामग्री के जीवनकाल को बढ़ा देते हैं जब वे धूप में उजागर होते हैं। इसी कारण निर्माण कंपनियां और कार निर्माता उन उत्पादों पर भारी मात्रा में निर्भर करते हैं जब भी उन्हें ऐसी सामग्री की आवश्यकता होती है जो लगातार मौसम के संपर्क में रहने के बावजूद जल्दी खराब न हो।

कठिन पर्यावरणों में एंटी-कॉरोशन गुण

कॉम्पैक्ट सिलिकॉन इमल्शन खराब मौसम या उद्योग रसायनों जैसी कठिन परिस्थितियों के सामने धातुओं को बेहतरीन सुरक्षा प्रदान करते हैं। उचित तरीके से लगाए जाने पर, ये कोटिंग धातु के जंग लगने की दर को धीमा कर देते हैं, जिसका मतलब है समय के साथ मरम्मत पर कम खर्च। वास्तविक दुनिया के परीक्षणों में भी कुछ शानदार परिणाम देखने को मिले हैं। एक कारखाने ने बताया कि सिलिकॉन आधारित सुरक्षा के उपयोग से जंग लगने में लगभग आधा कमी आई। इस तरह के प्रदर्शन से सामग्री सुरक्षित रहती है, भले ही उन्हें लगातार कठोर मौसम और रसायनों के संपर्क का सामना करना पड़ रहा हो, जो निर्माताओं के लिए उनके संचालन में बहुत महत्वपूर्ण है।

![]()

सुधारित स滑रण और सामग्री की मालवीयता

औद्योगिक यंत्रों में स्पर्श को कम करना

सिलिकॉन इमल्शन विभिन्न प्रकार की औद्योगिक मशीनों में स्नेहन में सुधार करने के लिए उपयोगी होते हैं। ये पदार्थ एक दूसरे के विरुद्ध घर्षण करने वाले भागों के बीच घर्षण और पहनने को कम करने में कमाल का काम करते हैं। उचित रूप से लगाए जाने पर, ये एक सुरक्षात्मक परत बनाते हैं जो धातु की सतहों को सीधे एक दूसरे के साथ रगड़ने से रोकती है, जिससे सब कुछ बहुत सुचारु रूप से काम करता है। लाभ केवल इतना नहीं है कि चीजें ठीक से चल रही हैं। उचित स्नेहन के साथ मशीनों में कम बिजली की खपत होती है और घटक अधिक समय तक चलते हैं। कारखानों के मालिकों के लिए, इसका मतलब है मरम्मत पर खर्च कम करना और समय के साथ अधिक काम पूरा करना। कई विनिर्माण संयंत्रों ने सिलिकॉन-आधारित समाधानों में स्विच करने के बाद रखरखाव खर्चों में काफी कमी देखी है, इसके अलावा उनका उत्पादन आउटपुट भी बढ़ जाता है। ये सभी कारक मिलकर दैनिक संचालन की दक्षता में वास्तविक अंतर लाते हैं।

पाने वाले कपड़ों की लचीलापन में सुधार

कॉम्पैक्ट सिलिकॉन इमल्शन में वस्त्र उद्योग ने कुछ काफी विशेष पाया है जब बात कपड़ों को अधिक लचीला बनाने की होती है। इसका मतलब यह है कि कपड़े त्वचा के साथ बेहतर महसूस करते हैं और नियमित उपयोग के दौरान अधिक समय तक चलते हैं। जो होता है, वह यह है कि ये इमल्शन कपड़े के तंतुओं पर एक बहुत पतली परत बनाते हैं जिससे सब कुछ मुलायम हो जाता है, जबकि इसकी स्थिरता बनी रहती है। कुछ अध्ययनों में वास्तव में यह दिखाया गया है कि इस तरह से उपचारित कपड़े पुरानी निपटान विधियों से प्राप्त परिणामों की तुलना में लंबे समय तक बने रहते हैं। फैशन डिज़ाइनर इसे खासकर पसंद करते हैं क्योंकि यह सीधे तौर पर इस बात को प्रभावित करता है कि प्रीमियम गारमेंट्स को छूने और पहनने में कैसा महसूस होता है। प्रीमियम ब्रांड्स को आराम के साथ-साथ यह भी महत्वपूर्ण होता है कि उत्पाद कितने समय तक चलेंगे जब तक उनका प्रतिस्थापन नहीं करना पड़ेगा।

प्लास्टिक और रबर में अटैच ऐप्लिकेशन

कॉम्पैक्ट सिलिकॉन इमल्शन में चिपकने वाली समस्या को रोकने के बहुत अच्छे लाभ होते हैं, जो प्लास्टिक और रबर के उत्पादों के निर्माण में बहुत महत्वपूर्ण होते हैं। ये सुनिश्चित करते हैं कि सामग्री साँचों से चिपके बिना बाहर आ जाए, जिससे उत्पादन प्रक्रिया के दौरान समय और परेशानी बचती है। उन कारखानों के लिए जो पूरे दिन अपनी क्षमता पर काम कर रहे होते हैं, यह विशेषता बहुत महत्वपूर्ण हो जाती है, क्योंकि व्यस्त समय में कोई भी समय या गुणवत्ता पर समझौता नहीं करना चाहता। जब सामग्री मशीनों से नहीं चिपकती, तो पूरी उत्पादन लाइन बेहतर चलती है, कम खराब वस्तुएँ बनती हैं, और कुल उत्पादन में वृद्धि होती है। मोटर वाहन उद्योग इन इमल्शन पर भारी रूप से निर्भर करता है जिनका उपयोग बिल्कुल सटीक आयामों वाले भागों के लिए किया जाता है, जबकि दैनिक उपभोक्ता वस्तुएँ बनाने वाली कंपनियाँ भी बड़े बैचों में उत्पादों के मानकों को बनाए रखने के लिए इन्हें बहुत उपयोगी पाती हैं।

पर्यावरण-अनुकूल सूत्रण और धैर्य

पर्यावरणीय प्रभाव को कम करने के लिए जीवनशील घटक

कॉम्पैक्ट सिलिकॉन इमल्शन में नवीनतम विकास में निर्माताओं द्वारा पर्यावरण पर पड़ने वाले प्रभाव को कम करने के प्रयास के तहत बायोडिग्रेडेबल घटकों की ओर महत्वपूर्ण स्थानांतरण हुआ है। इन ग्रीन विकल्पों के लिए बाजार तेजी से बढ़ रहा है, विशेष रूप से उन क्षेत्रों में जैसे कॉस्मेटिक्स और खाद्य पैकेजिंग, जहां स्थायित्व का सबसे अधिक महत्व है। जब कंपनियां ऐसे अवयवों को शामिल करना शुरू करती हैं जो समय के साथ विघटित हो जाते हैं, तो वे केवल अपशिष्ट को कम करने के अलावा पारिस्थितिकी तंत्र को स्वस्थ रखने में भी सहायता करती हैं। यह निश्चित रूप से उपभोक्ताओं की इको-उत्पादों में रुचि को समेटे हुए है, लेकिन इसका एक अन्य पहलू भी है: वैश्विक स्तर पर नियमों के अनुपालन के लिहाज से भी ये सूत्र व्यवसायों के लिए अनुकूल हैं। ऐसी कंपनियों के लिए, जो गुणवत्ता के त्याग के बिना ग्रीन होने के लिए प्रतिबद्ध हैं, बायोडिग्रेडेबल विकल्पों में स्विच करना दीर्घकालिक रूप से पर्यावरण और व्यवसाय दोनों के लिए उचित है।

उपभोक्ता में गैर-विषैली संरचना उत्पाद

कॉम्पैक्ट सिलिकॉन इमल्शन को सामान्यतः गैर-विषैला माना जाता है, जिसके कारण वे कई उपभोक्ता वस्तुओं के बाजारों में बहुत अच्छा काम करते हैं, खासकर त्वचा की देखभाल के उत्पादों और खाद्य निर्माण में उपयोग की जाने वाली वस्तुओं जैसी चीजों में। जब कंपनियां स्थापित सुरक्षा विनियमों का पालन करती हैं, तो ग्राहकों को उनके उत्पादों पर अधिक भरोसा होता है क्योंकि वे जानते हैं कि उनमें डाला गया पदार्थ वास्तव में स्पर्श या नियमित रूप से अंतःग्रहण करने के लिए सुरक्षित है। इस बात का मतलब है कि ये सामग्री स्वास्थ्य को नुकसान नहीं पहुँचाती हैं, जिसके कारण निर्माता उन्हें बच्चों के उत्पादों से लेकर रसोई के बर्तनों तक हर जगह बेच सकते हैं और ज्यादा जिम्मेदारी के मुद्दों के बारे में चिंता नहीं करते। क्योंकि लोग दैनिक वस्तुओं में छिपे रसायनों के बारे में अधिक जागरूक हो रहे हैं, त्वचा या पारिस्थितिक तंत्र को नुकसान न पहुंचाने वाले पदार्थों की मांग बढ़ती जा रही है। इस कारण, हम देख रहे हैं कि अधिक से अधिक कंपनियां अपने सूत्रों में कॉम्पैक्ट सिलिकॉन इमल्शन को शामिल कर रही हैं, केवल इसलिए कि वे उत्पाद सुरक्षा के आधुनिक अपेक्षाओं को पूरा करते हैं और साथ ही अच्छे प्रदर्शन विशेषताएं भी प्रदान करते हैं।

वैश्विक सुरक्षा मानकों का पालन

कॉम्पैक्ट सिलिकॉन इमल्शन के कई उत्पाद वास्तव में कठोर वैश्विक सुरक्षा आवश्यकताओं के अनुपालन में होते हैं, जिससे वे दुनिया भर में विभिन्न देशों में बिक्री के लिए उपयुक्त होते हैं। जब कंपनियां इन नियमों का पालन करती हैं, तो वे केवल अपने उत्पादों की सुरक्षा सुनिश्चित करने के अलावा कुछ और भी कर रही होती हैं। वे नए बाजारों में प्रवेश के द्वार भी खोल रहे होते हैं, जहां ग्राहक उत्पाद सुरक्षा के बारे में लेबल पर दिखाई देने वाली जानकारी पर भरोसा करते हैं। स्थानीय सीमाओं से आगे बढ़कर अपने व्यवसाय को बढ़ाने की इच्छा रखने वाले व्यवसायों के लिए इस प्रकार के अनुपालन का बहुत महत्व होता है। इन उत्पादों ने कठिन परीक्षण प्रक्रियाओं से गुजरकर अपनी गुणवत्ता और विश्वसनीयता साबित कर दी है। औद्योगिक खरीददारों और आम उपभोक्ताओं दोनों को यह जानकर सुकून मिलता है कि उत्पाद उच्च मानकों पर खरा उतरता है। परिणामस्वरूप, स्वास्थ्य सेवा, स्वचालित वाहन निर्माण, और यहां तक कि भोजन प्रसंस्करण जैसे क्षेत्रों से अधिक रुचि देखी जा रही है, जहां विश्वसनीय सामग्री हर चीज को बदल सकती है।

लागत-प्रभावी और बहु-उद्योगी लचीलापन

सॉल्वेंट-आधारित प्रणालियों का सस्ता वैकल्पिक

कॉम्पैक्ट सिलिकॉन इमल्शन व्यवसायों के लिए पुराने स्कूल के सॉल्वेंट आधारित सिस्टम की तुलना में बजट-अनुकूल विकल्प प्रदान करते हैं, जबकि नौकरी को उतना ही अच्छा करना अभी भी संभव है लेकिन काफी कम पैसों में। वे महंगे सॉल्वेंट विकल्पों की तरह लगभग एक ही तरीके से काम करते हैं लेकिन अतिरिक्त खर्च के बिना। उत्पाद की गुणवत्ता के बिना बलिदान किए कोने काटने की तलाश में छोटी दुकानों और मध्यम आकार के संचालन के लिए यह वास्तविक अंतर बनाता है। जब कंपनियां इन कॉम्पैक्ट सिलिकॉन इमल्शन में स्विच करती हैं, तो वे पूंजी को मुक्त करती हैं जो अन्यथा महंगे सॉल्वेंट खरीदने में चली जाती। इस मुक्त पूंजी को फिर नए उत्पाद विकास के लिए या नए बाजारों में विस्तार करने के लिए मार्गान्तरित किया जाता है बजाय लगातार बढ़ती सामग्री लागत से लड़ने के।

निर्माण और ऑटोमोबाइल क्षेत्रों में अनुप्रयोग

कॉम्पैक्ट सिलिकॉन इमल्शन अपने आपको कई अलग-अलग क्षेत्रों में उपयोगी साबित किया है, विशेष रूप से निर्माण कार्य और कार निर्माण में। निर्माता अक्सर उन्हें सीलेंट के रूप में उपयोग करते हैं क्योंकि वे सतहों पर अच्छी तरह से चिपकते हैं और लंबे समय तक चलते हैं, जो इमारतों को वर्षों तक जोखिम के बाद मौसम के नुकसान के खिलाफ बेहतर ढंग से खड़ा करने में मदद करता है। कार निर्माता भी इन्हीं सामग्रियों को उपयोगी पाते हैं। वे उन्हें लेप के रूप में लागू करते हैं जो वाहनों पर अच्छी तरह से दिखते हैं लेकिन साथ ही साथ खरोंच और यूवी क्षति के खिलाफ सुरक्षा भी प्रदान करते हैं। एक सामग्री का यह तथ्य कि इतनी ज्यादा चीजें कर सकती हैं इस बात का मतलब है कि कंपनियां सिलिकॉन तकनीक से वास्तविक मूल्य प्राप्त करती हैं। निर्माण फर्म मरम्मत पर पैसे बचाती हैं जबकि ऑटो निर्माता लंबे समय तक चलने वाले फिनिश के साथ ग्राहक संतुष्टि में वृद्धि करते हैं। क्योंकि अधिक उद्योग यह पता लगा रहे हैं कि ये इमल्शन क्या कर सकते हैं, हम रोजमर्रा के उत्पादों में उपयोग करने के लिए और भी रचनात्मक तरीकों को देखने वाले हैं।

प्रक्रियाओं के बीच उत्पादन की कुशलता का अधिकतमीकरण

कॉम्पैक्ट सिलिकॉन इमल्शन उत्पादन इकाइयों में काफी प्रभाव डाल रहे हैं, जहां ये दक्षता और उत्पादन लाइन से निकलने वाले उत्पादों दोनों में सुधार कर रहे हैं। जब इन सूत्रों का उपयोग उद्योगिक कोटिंग्स या मशीन लुब्रिकेंट्स जैसी चीजों में किया जाता है, तो ये प्रसंस्करण समय को कम करते हैं, जबकि सामग्री के अपशिष्ट को न्यूनतम रखते हैं। वास्तविक सफलता क्या है? उत्पाद अधिक सुचारु रूप से प्रक्रिया में सिलिकॉन के अनुप्रयोग के कारण असेंबली लाइन से कम दोषों के साथ निकलते हैं। आदेशों के साथ रखरखाव में संघर्ष कर रहे निर्माताओं के लिए, इसका अर्थ है खुश ग्राहक जो विश्वसनीय उत्पाद प्राप्त करते हैं जो वादे के अनुसार प्रदर्शन करते हैं। स्वचालित भाग बनाने वालों से लेकर खाद्य पैकेजिंग संयंत्रों तक, छोटे और बड़े दोनों व्यवसाय यह पाते हैं कि कॉम्पैक्ट सिलिकॉन इमल्शन में स्विच करने से समय के साथ-साथ लागत बचत और उत्पाद गुणवत्ता में सुधार दोनों के मामले में लाभ होता है।

सामान्य प्रश्न

कॉम्पैक्ट सिलिकॉन एमल्शन क्या हैं?

वे सिलिकॉन तेल और पानी के विशेष मिश्रण हैं, जिन्हें औद्योगिक अनुप्रयोगों के लिए सरफ़ैक्टेंट्स द्वारा स्थिर किया गया है।

सिलिकॉन एमल्शन के मुख्य उपयोग क्या हैं?

उनका उपयोग कार, पाठक संगठन, व्यक्तिगत देखभाल उत्पादों और निर्माण सामग्री में किया जाता है।

सिलिकॉन एमल्शन उत्पादों की डुरेबिलिटी को कैसे सुधारते हैं?

वे पानी और UV से प्रतिरोध देते हैं, सामग्रियों को विघटन से बचाते हैं।

क्या सिलिकॉन एमुल्शन पर्यावरण के अनुकूल हैं?

नए सूत्र घटिया पर्यावरण प्रभाव के लिए जैविक रूप से पारदर्शी घटकों पर केंद्रित हैं।

क्या वे सुरक्षा मानकों का पालन करते हैं?

हाँ, कई उत्पाद वैश्विक सुरक्षा मानकों को पूरा करते हैं, ग्राहकों की सुरक्षा और पैमाने पर वृद्धि सुनिश्चित करते हैं।