Inleiding tot Uitbreidbare microsferen en Materiaalkwaliteit

Wat zijn expandeerbare microsferen

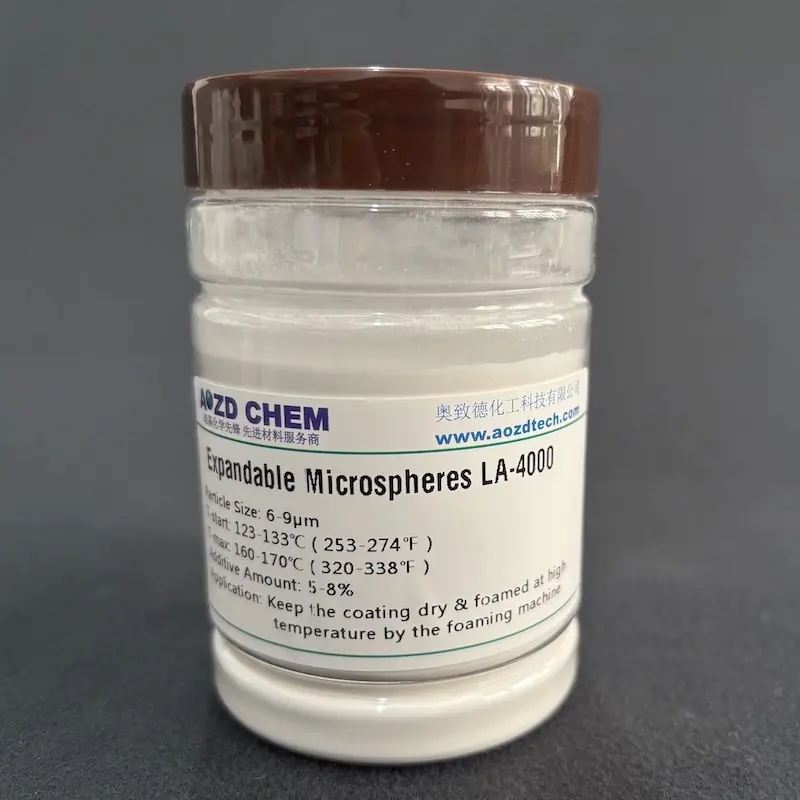

Uitbreidbare microsferen bestaan uit kleine holle polymeerballen die gevuld zijn met gas. Wanneer deze worden verwarmd, zetten ze daadwerkelijk uit. De meeste van deze kleine bolletjes hebben een diameter tussen de ongeveer 10 en 100 micrometer, hoewel de exacte afmetingen kunnen variëren afhankelijk van de toepassing. In de wereld van materialen is er de laatste tijd steeds meer belangstelling voor deze microbolletjes in verschillende sectoren zoals auto's, gebouwen en alledaagse producten, omdat ze helpen het gewicht van materialen te verlagen terwijl de isolerende eigenschappen verbeteren. Wat ze zo nuttig maakt, is hun geringe gewicht en lage dichtheid. Dit stelt fabrikanten in staat samengestelde materialen te maken die goed presteren zonder te zwaar of duur te zijn. Bovendien zijn de isolerende voordelen erg belangrijk voor dingen als elektronische apparaten, waar het koel houden van onderdelen essentieel is, en voor verpakkingen waarbij het beschermen van de inhoud tegen temperatuurschommelingen cruciaal blijft.

Rol in hedendaagse materiaalwetenschap

Uitbreidbare microsferen zijn tegenwoordig vrij belangrijk geworden bij het ontwikkelen van betere materialen voor diverse industrieën, waaronder de lucht- en ruimtevaart en de auto-industrie. Deze minuscule sferen verbeteren de prestaties van producten doordat ze de mechanische sterkte verhogen en aanzienlijk helpen bij het verminderen van het gewicht. Neem als voorbeeld de automobielindustrie, waar fabrikanten deze microsferen in verschillende onderdelen verwerken, zodat voertuigen lichter zijn zonder dat de sterkte wordt gecompromitteerd. Dit leidt logischerwijs tot een beter brandstofverbruik. Uit diverse tests en experimenten blijkt dat deze kleine bolletjes daadwerkelijk de treksterkte en hittebestendigheid verhogen wanneer ze gemengd worden in kunststoffen en andere polymeren. Het vermogen om lichtere, maar toch sterke producten te maken, is tegenwoordig van groot belang in de markt, waar bedrijven strikte regels moeten naleven met betrekking tot energieverbruik en koolstofuitstoot, terwijl ze tegelijkertijd kwalitatief goede, duurzame producten moeten blijven leveren.

Lichte en duurzame materialen gemaakt mogelijk door expansieve microsferen

Innovaties in de automobielsector

Automobilisten gebruiken steeds vaker zogenaamde uitdijende microsferen om hun voertuigen lichter te maken, waardoor auto's minder brandstof verbruiken. Wanneer deze kleine sferen in onderdelen zoals bumpers, instrumentenpanelen en zelfs bepaalde kunststofcomponenten in de carrosserie worden verwerkt, kunnen fabrikanten het totale gewicht verminderen terwijl de benodigde sterkte behouden blijft. Sommige studies laten zien dat bedrijven bij gebruik van deze microsferen in hun ontwerpen vaak een gewichtsvermindering van ongeveer 20% bereiken. Dat betekent beter brandstofverbruik voor de bestuurder en minder schadelijke uitstoot in de atmosfeer. Aangezien regelgevers momenteel streven naar schonere transportopties, biedt dit soort innovatie autofabrikanten een reële kans om te voldoen aan de strenge milieunormen.

Vergissingen in Bouwmateriaal

Uitdijbare microsferen veranderen momenteel het bouwbedrijf, vooral wat betreft het verbeteren van materialen zoals beton en isolatieplaten. Wanneer bouwers deze kleine sferen mengen in hun materialen, verkrijgen zij betere isolatie, omdat warmte minder gemakkelijk wordt doorgelaten. Dat betekent dat gebouwen in de winter warmer en in de zomer koeler blijven, zonder extra verwarming of koeling. Wat echt geweldig is, is dat deze microsferen materialen juist sterker maken terwijl ze licht van gewicht blijven. Stel je voor - sterkere muren die niet een ton wegen? Dat is vrijwel ieder aannemers droom. De bouwsector streeft al jaren naar lichtere materialen, iets wat duidelijk blijkt uit al die ASTM-standaarden die we steeds weer horen. Geen wonder dat steeds meer architecten producten specificeren die met microsferen zijn verrijkt. Het is gewoon verstandig voor zowel het milieu als de kosten.

Deze innovaties in de automobiel- en bouwsector onderstrepen de belangrijke rol die uitbreidbare microsferen spelen bij het creëren van lichte, duurzame en energie-efficiënte materialen die voldoen aan de industrie-eisen voor prestaties en duurzaamheid.

Verbeterde thermische en akoestische isolatieeigenschappen

Thermische weerstand in bouwmateriaalen

Uitbreidbare microsferen maken een groot verschil in hoeverre bouwmaterialen goed isoleren tegen warmte, waardoor de energiekosten in de bouwsector kunnen worden verlaagd. Deze kleine sferen hebben namelijk thermoplastische wanden die gevuld zijn met gas. Tijdens het productieproces zetten ze uit wanneer ze blootgesteld worden aan warmte. Wat daarna gebeurt, is vrij bijzonder: bij het uitzetten vormen ze vele kleine luchtpockets binnen de materialenmatrix. Deze pockets fungeren als barrière tegen warmtestroom, waardoor producten zoals betonblokken en isolatieplaten veel beter worden in het behouden van een stabiele temperatuur. Wij hebben ook daadwerkelijke resultaten gezien van het gebruik van deze microsferen in isolatieproducten. In één specifieke toepassing werd warmteverlies via muren met ongeveer 30% teruggebracht, volgens testgegevens. Dit betekent op de lange termijn aanzienlijke besparingen op HVAC-systemen. Aangezien duurzaamheid binnen de architectuur steeds belangrijker wordt, is het toepassen van deze microsferen niet alleen een milieuvriendelijke keuze, maar ook een slimme kostenbespaarstrategie voor toekomstgerichte bouwers.

Geluidsisolatieleoplossingen voor voertuigen

Uitzetbare microbolletjes zijn in auto's erg nuttig geworden voor het absorberen van geluid en het stiller maken van de rit voor passagiers. Wanneer fabrikanten deze kleine bolletjes in onderdelen zoals het dashboard en onder de panelen aanbrengen, verminderen ze het wegverkeerslawaai vrij effectief. Wat deze technologie interessant maakt, is dat er materialen worden gecreëerd die minder wegen, maar nog steeds goed functioneren bij het tegenhouden van ongewenste geluiden die door de cabine trillen. Sommige studies tonen aan dat voertuigen uitgerust met deze technologie tot wel de helft minder lawaai kunnen maken dan voertuigen zonder, waardoor chauffeurs en passagiers tijdens hun reizen een veel rustiger sfeer ervaren. Naast het verminderen van geluid helpt deze technologie ook om auto's in totaal lichter te maken, wat betekent dat er minder brandstof wordt verbruikt en er minder uitstoot is.

Verbeterde esthetische kwaliteiten door integratie van microsferen

Gladde texturen in consumentengoederen

Producten die uitdijbare microsferen bevatten, zien er over het algemeen beter uit en voelen ook prettiger aan, vooral wanneer we ze met onze huid of handen aanraken. Wanneer fabrikanten deze kleine sferen aan hun formules toevoegen, resulteren de producten in een fijner oppervlak en een aangenamere textuur in brede zin. Daarom zien we ze steeds vaker terug in make-up- en verzorgingsproducten. Denk aan die luxe gezichtscrèmes die soepel en zonder resten aan te brengen zijn. Ook voor huishoudelijke artikelen voegen bedrijven microsferen toe om oppervlakken te creëren die gewoon lekker aanvoelen in de hand, waardoor consumenten ze vaker willen kopen. Recente marktonderzoeken laten zien dat mensen zich steeds meer laten trekken tot producten die simpelweg fijner aanvoelen bij het aanraken, en textuur is uitgegroeid tot één van de belangrijkste manieren waarop merken zich kunnen onderscheiden van concurrenten in de schappen.

Matte finish in industriële coatings

Uitzetbare microbolletjes helpen fabrikanten bij het behalen van die gewenste matte afwerkingen in industriële coatings, waardoor producten zowel beter eruitzien als praktische voordelen bieden. Waardoor zijn deze kleine bolletjes zo effectief? Ze creëren een consistente oppervlaktetekstuur die niet reflecteert onder belichting. Dat betekent dat coatings er aantrekkelijker uitzien voor het oog en langer meegaan dan glanzende alternatieven. De automobielindustrie heeft deze technologie goed opgenomen, net als elektronicafabrikanten die willen dat hun apparaten die professionele, niet-reflecterende afwerking krijgen die consumenten aantrekkelijk vinden. Praktijktests tonen aan dat onderdelen met coating niet alleen beter eruitzien, maar ook aanzienlijk langer meegaan. Veel bedrijven melden tevredenere klanten wanneer ze overschakelen op coating op basis van microbolletjes, wat logisch is als je bedenkt hoe belangrijk eerste indrukken zijn in een concurrerende markt.

Kosten-efficiëntie en Duurzaamheidsvoordelen

Verlaging van de consumptie van grondstoffen

Het toevoegen van uitdijende microsferen aan productformules zorgt ervoor dat bedrijven minder grondstoffen hoeven aan te schaffen. Wanneer verhit, zwellen deze kleine bolletjes op tot ongeveer 60 keer groter dan hun oorspronkelijke formaat. Dat betekent dat fabrieken met veel minder materiaal toe kunnen maar nog steeds hetzelfde oppervlak kunnen bedekken en even goed blijven presteren. De kostenbesparing is ook behoorlijk indrukwekkend. Bedrijven melden dat zij ongeveer 15% besparen op materialen wanneer zij overstappen op microsferen, wat zeker helpt om de productiekosten te verlagenen. Wat deze technologie zo aantrekkelijk maakt, is dat deze werkt op verschillende schalen en toepassingen. Van coatings tot kunststoffen, producenten grijpen steeds vaker naar microsferen terwijl zij proberen afval te verminderen zonder in te boeten aan kwaliteit.

Milieuvriendelijke productieprocessen

Wat betreft duurzaamheid brengen uitdijbare microsferen verschillende voordelen met zich mee, vooral als je kijkt naar de manier waarop ze de benodigde energie tijdens het productieproces verminderen. Aangezien deze kleine sferen minder grondstoffen in beslag nemen, leidt dit logischerwijs tot een lagere energieconsumptie gedurende het productieproces en tegelijkertijd ook tot een verminderde impact op het milieu. Uit diverse levenscyclusanalyses blijkt dat producten die met microsferen worden vervaardigd ongeveer 25% kleinere koolstofvoetafdrukken achterlaten in vergelijking met conventionele productiemethoden. Een recente branche rapportage merkte zelfs op dat het gebruik van deze kleine hulpjes fabrikanten in staat stelt om op een schonere manier producten te maken, simpelweg omdat er minder afval wordt gegenereerd en de energiebehoefte aanzienlijk daalt. Voor bedrijven die echt geïnteresseerd zijn in duurzaamheid zonder afbreuk te doen aan kwaliteit of prestaties, is het opnemen van uitdijbare microsferen in hun productieprocessen zowel milieutechnisch als economisch gezien verstandig.

FAQ Sectie

Welke industrieën gebruiken uitbreidbare microsferen vaak?

Uitbreidbare microsferen worden breed gebruikt in industrieën zoals automotief, bouw, consumentengoederen, luchtvaart en elektronica.

Hoe bijdragen uitbreidbare microsferen tot energieëfficiëntie?

Uitbreidbare microsferen verbeteren de thermische isolatieeigenschappen, verlagen het gewicht en verminderen het materiaalgebruik, wat leidt tot een hogere energieëfficiëntie in bouwmateriaalen en voertuigonderdelen.

Zijn uitbreidbare microsferen milieuvriendelijk?

Ja, ze verminderen het gebruik van grondstoffen, verlagen het energieverbruik bij de productie en reduceren de koolstofvoetafdruk, waardoor ze milieuvriendelijker zijn dan traditionele materialen.

Verbeteren uitbreidbare microsferen het uiterlijk van producten?

Ja, ze verbeteren de textuur en het uiterlijk van consumentengoeien en bieden matige afwerkingen in industriële coatings.

Inhoudsopgave

- Inleiding tot Uitbreidbare microsferen en Materiaalkwaliteit

- Lichte en duurzame materialen gemaakt mogelijk door expansieve microsferen

- Verbeterde thermische en akoestische isolatieeigenschappen

- Verbeterde esthetische kwaliteiten door integratie van microsferen

- Kosten-efficiëntie en Duurzaamheidsvoordelen

- FAQ Sectie