Zrozumienie technologii mikrosfer rozszerzalnych typu Compact Expandable

Skład podstawowy i mechanizm działania

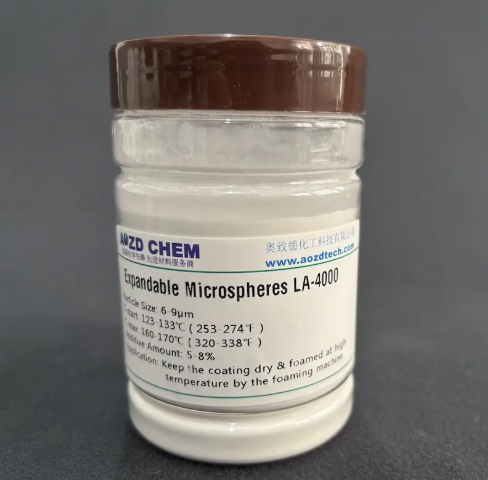

Podstawowa formuła do użycia dla kompaktowych rozwijających się mikrokul to kombinacja polimerów i addytyw zaprojektowanych tak, aby zapewnić najlepsze możliwe właściwości rozszerzania. Te kule są zazwyczaj puste termoplastyczne kule wypełnione gazem, który rozszerza się pod wpływem ciepła, więc gdy kule są narażone na ciepło, bardzo się rozszerzają. Rozszerzanie jest spowodowane przez ciepło i tworzy strukturę komórkową, która nadaje mikrokulom właściwości mechaniczne, jednocześnie zmniejszając wagę materiału. Na przykład, mikrokule rozwijające się mogą osiągnąć objętościowe rozszerzenie aż do 60 razy większej od ich pierwotnego rozmiaru. Ta wybitna wydajność czyni je kluczowym elementem w zastosowaniach takich jak lekkie materiały budowlane i przemysł samochodowy. Ponadto, stosowanie takich mikrokul rozwijających się jest bardzo przyjazne dla środowiska, ponieważ zmniejszają one zużycie surowców i energii produkcyjnej w porównaniu do tradycyjnych materiałów, co również jest bardzo godne pochwały.

Rola w nowoczesnym inżynierii materiałów

Kompaktowy rozwijalne mikrokule kształtują przyszłość nauki o materiałach, oferując ekscytujące możliwości w szerokim zakresie sektorów. W budownictwie pozwalają na tworzenie bardziej efektywnych i dłużej trwających materiałów. W motoryzacji umożliwiają redukcję masy elementów pojazdów dzięki zastosowaniu mikrosfer, co może zmniejszyć wagę aż o 20%, przyczyniając się do oszczędności paliwa i spełnienia rygorystycznych norm emisji. Tendencja lekkich konstrukcji idzie w parze z zrównoważonym rozwojem, ponieważ mikrosfery zużywają mniej materiału. Ich potencjał jest nadal odkrywany dzięki ciągłym badaniom i postępom w technologii mikrosfer. Prace prowadzone przez uczelnie pokazują postęp w zakresie właściwości mechanicznych (wytrzymałości na rozciąganie i właściwości termicznych) oraz materiałów polimerowych. Wobec trendu lekkich konstrukcji i ochrony środowiska w różnych branżach, mikrosfery rozszerzalne odgrywają istotną ekologiczną i innowacyjną rolę w przemyśle materiałowym.

Redukcja wagi bez utraty wytrzymałości

Lekkość elementów samochodowych

Kompaktowe, rozwijane mikrokule zajmują teraz centralne miejsce w zasadach lekkości samochodów, oferując wybitny kompromis między redukcją wagi a utrzymaniem wytrzymałości. Do producentów samochodowych, którzy stosują te materiały dla części takich jak bumpery i panele deski rozdzielczej, aby znacząco zmniejszyć wagę pojazdu, jednocześnie zachowując wytrzymałość, należą m.in. Ford i BMW. Badania wskazują, że mikrokule mogą zmniejszyć wagę o maksymalnie 20 procent, co przekłada się bezpośrednio na korzyści w postaci oszczędności paliwa i emisji, według badań. Regulacje w sektorze samochodowym stają się coraz surowsze w kwestii zużycia paliwa i redukcji emisji, a zastosowanie rozwijanych mikrokul przedstawia się jako interesujące rozwiązanie. Nowe zaawansowane materiały pozwalają producentom spełniać wymagania regulacyjne oraz oczekiwania konsumentów na czystsze pojazdy.

Materiały Budowlane Wysokiej Wytrzymałości

W przemyśle budowlanym gęstość materiałów jest rewolucjonizowana przez MECS, które zwiększają wytrzymałość bez dodawania wagi. Te mikrokule są wykorzystywane w betonie i tablicach izolacyjnych, aby stworzyć materiały budowlane o świetnych właściwościach. Projekty, takie jak budynek EcoBlox, już wykorzystały materiały wzmacniane mikrokulami w tych nowych kontekstach, co pozwoliło na zwiększenie efektywności i zrównoważonego rozwoju budownictwa. Certyfikaty od źródeł opierających się na standardach ASTM gwarantują, że materiał jest bezpieczny i wysokiej jakości. Analizy pokazują również, że konwencjonalne materiały są znacząco gorsze niż materiały zawierające rozwijalne mikrokule pod względem trwałości i wydajności. Wybierając te inteligentne materiały wewnętrzne, budowniczowie nie tylko mogą spełnić, ale przekroczyć wymagania dotyczące zrównoważonego rozwoju dla dzisiejszych budynków, które są trwałe i oszczędne energetycznie, jednocześnie będąc przyjazne środowisku.

Zwiększone Właściwości W Spęku i Piankach

Poprawa Elastyczności W Spęku Przemysłowym

Rozwijalne mikrokule są niezastąpione w poprawie zarówno elastyczności, jak i odporności na uderzenia pokryć przemysłowych. Dzięki ich zastosowaniu producenci mogą nadać pokryciom zdolność wytrzymywania ekstremalnych warunków, takich jak narażenie na chemikalia i ekstremalne temperatury. Automatyka i budownictwo to najlepsze przykłady branż, w których dłuższy żywot i lepsza wydajność pokryć oznaczają lepszą bezpieczeństwo i efektywność pojazdów oraz konstrukcji. Na przykład jeden raport branżowy wskazał, że dodanie mikrokul do pokryć oferuje o 15% lepszą odporność na zużycie w porównaniu z niezmodyfikowanymi pokryciami. Po zastosowaniu mikrokule mieszane w materiałach pokrywowych rozszerzają się pod wpływem нагrzewania, tworząc silną, elastyczną barierę, która lepiej przylega i trwa dłużej.

Techniki optymalizacji gęstości pianki

Jest to również dobra praktyka wykorzystanie wypuszczanych mikrokul do kontrolowania gęstości produktu piankowego, zwłaszcza gdy chcemy skutecznie spakować np. izolację lub amortyzację. W zależności od ilości dodanych mikrokul gęstość może być dostosowana do pożądanego poziomu w celu optymalizacji właściwości termicznych i amortyzacyjnych produktu. Niektóre branże, takie jak opakowania żywnościowe, meble tapicerowane i motoryzacyjne, bardzo korzystają z tych ulepszeń. Na przykład, koszty surowcowe w produkcji pianek mogą zostać obniżone o do 20%, dzięki wykorzystaniu rozwijających się mikrokul, co zapewnia atrakcyjne korzyści kosztowe. Ten kompromis między zmniejszaniem gęstości a utrzymaniem wydajności gwarantuje, że materiały piankowe są zarówno kosztowo efektywne, jak i wysokiej jakości.

Wyjątkowe właściwości izolacji termicznej

Rozwiązania budowlane oszczędzające energię

Kompaktowo-rozwijalne mikrokule są rewolucyjne w budownictwie i pakowaniu oszczędzającym energię. Te materiały oferują strukturę komórkową, która obniża przewodnictwo cieplne, jak to zostało udowodnione w wielu ikonicznych budynkach w imię efektywności energetycznej. Na przykład, budynki konstrukcyjne, które wykorzystują izolację zwiększoną o mikrokule, zaoszczędziły do 30% kosztów energii poprzez zmniejszenie utraty ciepła. Długoterminowe korzyści są ogromne - niższe rachunki energetyczne i mniejszy odciśnienie węglowe ze względu na zmniejszoną zależność od ogrzewania i chłodzenia. Jest to w idealnej harmonii z rosnącym popytem na przyjazne środowisku materiały budowlane, skupiając się na równowadze między wydajnością ekonomiczną a ekologiczną dzięki użyciu zaawansowanych technologii izolacji termicznej.

Wydajność izolacji w ekstremalnych warunkach

Oznaczenia ISO są najlepiej wykorzystywane w warunkach niskich temperatur i zimnego klimatu. Wyjątkowe właściwości izolacyjne materiału czynią go niezależnym od warunków atmosferycznych, czy to ciepło czy zimno. Studia przypadków pokazały, że izolacja mikrokulowa działała pomyślnie w ekstremalnych warunkach atmosferycznych, potwierdzając ich trwałość. Ponadto, udowodniono, że te materiały są lepszym materiałem izolacyjnym w porównaniu do jakichkolwiek tradycyjnych materiałów izolacyjnych pod względem oporu termicznego. To ważne w utrzymaniu stabilnego klimatu wewnętrznego i poprawie efektywności energetycznej, zwłaszcza w niekorzystnych środowiskach, gdzie tradycyjne materiały mogą nie działać. Oceny oporu termicznego są wskaźnikiem tego, jak dobrze izolacja mikrokulowa radzi sobie z czasem, niezależnie od klimatu.

Zastosowania w Poprawie Pokrycia Powierzchniowego

Rozwój Gładkiej Struktury w Produktach Konsumenta PRODUKTY

System jednostkowych rozwijających się mikrokul jest zmieniał właściwości powierzchniowe produktów konsumpcyjnych w różne formy wykończenia, poprawiając stopień gładkości. Te mikrokule są w dużej mierze odpowiedzialne za wytworzenie tekstury aksamitnej w produktach takich jak kosmetyki i artykuły domowe. Najwyższej klasy marki kosmetyczne korzystają z tej technologii, aby tworzyć ekscytujące kremy i lokacje o teksturze aksamitnej, idealne dla rosnącego popytu na luksusowe tekstury ze strony konsumentów. Ponieważ miękka tekstura zgadza się z preferencjami konsumentów, produkty o miękkiej teksturze osiągają wysokie satysfakcje w danych badawczych rynku. Konsументy skupiają się na produktach, które nie tylko działają, ale działają pięknie i zapewniają cudowne doświadczenie dotykowe, co zwiększa popyt na nowatorskie tekstury produktów.

Postępy w dziedzinie matowego wykończenia w projektowaniu przemysłowym

Użycie ekspandowalnych mikrokul jest kluczowe do uzyskania matowych, opornych na zadrapania powierzchni w projektowaniu przemysłowym. W branżach, takich jak motoryzacja i elektronika, gdzie produkty niezanieczyszczone są często wymaganiem, te mikrokule pomagają w produkcji przedmiotów o jednolitym matowym wykończeniu. Na przykład, matowe wykończenia pokryw samochodowych stały się standardami branży z powodu postrzeganego wartości (estetyka) i z powodu funkcjonalnych. Badania wskazują, że zarówno konsumentów, jak i projektantów przyciąga trend matowych wykończeń. Mikrokule są kluczowe w przepisach technologicznych, które opierają się na doskonałym wykończeniu powierzchni, dobrym sterowaniu wyglądem i trwałością, ale nie wymagają/nie potrzebują wysokowydajnej żywicy.

Sekcja FAQ

Co to są kompaktowe rozwijające się mikrokule?

Kompaktowe rozwijające się mikrokule to maleńkie kuliste cząstki złożone z polimerowej skorupy wypełnionej gazem. Rozszerzają się one pod wpływem ciepła, tworząc strukturę komórkową, która ulepsza właściwości materiału.

Jak mogą być korzystne rozszerzalne mikrokule w budownictwie?

W budownictwie rozszerzalne mikrokule zwiększają wytrzymałość i efektywność materiałów, prowadząc do bardziej trwały i zrównoważonych materiałów budowlanych. Zmniejszają wagę, zachowując integralność strukturalną.

Dlaczego stosuje się mikrokule w przemyśle samochodowym?

Mikrokule zmniejszają wagę elementów samochodowych, co prowadzi do lepszej efektywności spalania i niższych emisji, co zgadza się z regulacjami branżowymi i popytem konsumentów na bardziej ekologiczne pojazdy.

Jak mikrokule poprawiają wydajność przemysłowych pokryć powierzchniowych?

Mikrokule zwiększają giętkość i wytrzymałość przemysłowych pokryć, zapewniając, że pozostają nietknięte w warunkach surowych, co przedłuża czas życia pokrytych produktów.

Czy mikrokule mogą przyczynić się do efektywności energetycznej?

Tak, mikrokule znacząco zwiększają izolację termiczną, redukując przenikanie ciepła i oszczędzając koszty energii, czyniąc je odpowiednie dla rozwiązań budowlanych oszczędzających energię.

Spis treści

- Zrozumienie technologii mikrosfer rozszerzalnych typu Compact Expandable

- Redukcja wagi bez utraty wytrzymałości

- Zwiększone Właściwości W Spęku i Piankach

- Wyjątkowe właściwości izolacji termicznej

- Zastosowania w Poprawie Pokrycia Powierzchniowego

-

Sekcja FAQ

- Co to są kompaktowe rozwijające się mikrokule?

- Jak mogą być korzystne rozszerzalne mikrokule w budownictwie?

- Dlaczego stosuje się mikrokule w przemyśle samochodowym?

- Jak mikrokule poprawiają wydajność przemysłowych pokryć powierzchniowych?

- Czy mikrokule mogą przyczynić się do efektywności energetycznej?