Surface texture plays a crucial role in determining the performance, aesthetics, and functionality of countless industrial products. From automotive coatings to consumer electronics, the ability to achieve precise surface characteristics can make the difference between product success and failure. Expancel microspheres have emerged as a revolutionary solution for manufacturers seeking to enhance surface texture while maintaining material integrity and reducing overall weight.

These innovative expandable microspheres offer unique properties that enable precise control over surface roughness, porosity, and tactile characteristics. When incorporated into various formulations, they create distinctive surface profiles that enhance both functional and aesthetic properties. The technology behind these microspheres represents a significant advancement in materials science, providing manufacturers with unprecedented control over surface engineering.

Understanding Expandable Microsphere Technology

Core Composition and Structure

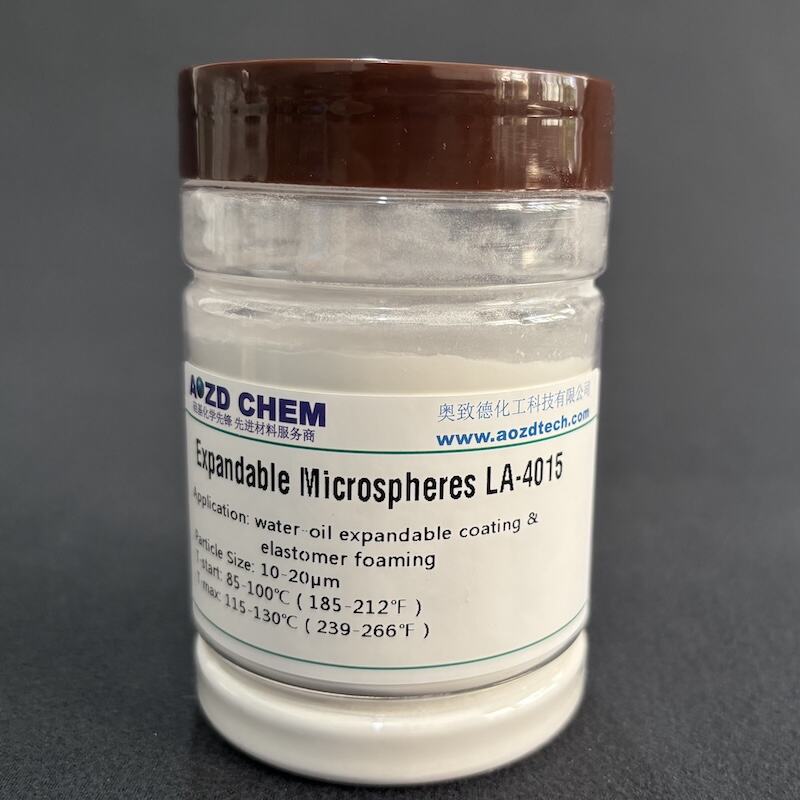

Expandable microspheres consist of a thermoplastic shell containing a hydrocarbon blowing agent. The shell material, typically made from acrylonitrile or vinyl chloride copolymers, provides structural integrity while remaining flexible enough to expand under controlled conditions. This unique composition allows for predictable expansion behavior when exposed to specific temperature ranges.

The internal blowing agent transforms from liquid to gas when heated, creating internal pressure that causes the microsphere to expand dramatically. This expansion can increase the original diameter by up to five times, resulting in hollow, lightweight spheres that significantly alter the material properties of the host substrate. The precise control over expansion parameters enables manufacturers to achieve consistent surface texture results.

Activation Mechanisms and Control

Temperature activation serves as the primary mechanism for microsphere expansion, with different grades designed for specific temperature ranges. This thermal responsiveness allows for integration into various manufacturing processes, from low-temperature applications around 80°C to high-temperature processes exceeding 200°C. The ability to select appropriate activation temperatures ensures compatibility with existing production workflows.

Process control parameters such as heating rate, dwell time, and cooling conditions directly influence the final surface characteristics. Rapid heating promotes uniform expansion, while controlled cooling prevents collapse and maintains the desired texture profile. Understanding these relationships enables manufacturers to fine-tune their processes for optimal results.

Surface Texture Enhancement Mechanisms

Roughness and Topography Modification

The expansion of microspheres within a coating or substrate creates localized surface irregularities that contribute to increased roughness and unique topographical features. These surface modifications occur at the microscopic level, creating patterns that are difficult to achieve through traditional texturing methods. The random distribution of expanded spheres produces naturally occurring surface variations that enhance visual appeal.

Surface roughness parameters such as Ra, Rz, and Rq can be precisely controlled by adjusting microsphere concentration, size distribution, and expansion conditions. Higher concentrations typically result in more pronounced texture effects, while varying particle sizes create multi-scale roughness patterns. This level of control allows manufacturers to meet specific surface requirements for different applications.

Tactile Property Enhancement

Beyond visual improvements, Expancel microspheres significantly enhance tactile properties by creating surfaces with improved grip, reduced slipperiness, and enhanced sensory feedback. The microscopic texture created by expanded spheres provides increased surface area for contact, improving friction characteristics without compromising durability.

These tactile improvements prove particularly valuable in applications requiring enhanced user interaction, such as control surfaces, handles, and touch-sensitive interfaces. The ability to create soft-touch surfaces while maintaining underlying structural properties opens new possibilities for product design and user experience enhancement.

Industrial Applications and Benefits

Automotive Surface Solutions

The automotive industry has embraced Expancel microspheres for creating sophisticated interior surfaces that combine aesthetic appeal with functional benefits. Dashboard components, door panels, and trim pieces benefit from the improved tactile properties and reduced glare characteristics that result from microsphere-enhanced surfaces. These applications also contribute to weight reduction goals while maintaining durability requirements.

Exterior automotive applications include textured coatings for bumpers, wheel wells, and protective films where enhanced surface properties provide both functional and aesthetic advantages. The ability to create consistent texture patterns across large surface areas while maintaining color stability makes these microspheres ideal for automotive surface engineering applications.

Consumer Electronics and Appliances

Consumer electronics manufacturers utilize Expancel microspheres to create premium surface finishes that enhance user experience and product differentiation. Mobile device cases, appliance housings, and control interfaces benefit from the improved grip and tactile feedback provided by microsphere-enhanced surfaces. These applications often require precise control over surface properties to meet both functional and aesthetic requirements.

The anti-fingerprint properties resulting from microsphere texturing prove particularly valuable in consumer electronics applications. The microscopic surface structure disrupts the formation of visible fingerprints while maintaining smooth operation of touch-sensitive surfaces. This combination of functionality and cleanliness represents a significant advantage in consumer-facing applications.

Processing and Integration Methods

Coating and Paint Systems

Integration of Expancel microspheres into coating systems requires careful consideration of compatibility, dispersion methods, and processing conditions. Proper dispersion ensures uniform distribution throughout the coating matrix, preventing agglomeration that could lead to inconsistent surface properties. Mixing protocols typically involve gradual addition of microspheres to pre-mixed base formulations under controlled agitation conditions.

The timing of microsphere addition relative to other coating components affects final performance characteristics. Early addition allows for better dispersion but may require modified storage conditions, while late addition preserves microsphere integrity but may compromise dispersion quality. Understanding these trade-offs enables formulators to optimize their processes for specific applications.

Polymer and Composite Integration

Direct incorporation of Expancel microspheres into polymer matrices offers opportunities for creating textured surfaces during the molding or extrusion process. This approach eliminates secondary coating operations while providing integrated surface texture that cannot be removed through normal wear. Proper selection of expansion temperature relative to processing conditions ensures optimal timing of microsphere activation.

Composite applications benefit from the dual functionality of microspheres, which provide both surface texture enhancement and density reduction. This combination proves particularly valuable in applications where weight reduction and surface properties are equally important. The integration process requires careful attention to temperature profiles to prevent premature expansion or incomplete activation.

Quality Control and Performance Optimization

Measurement and Characterization

Effective quality control for microsphere-enhanced surfaces requires specialized measurement techniques that capture both macro and micro-scale surface characteristics. Profilometry, scanning electron microscopy, and optical measurement methods provide complementary data on surface topography, texture uniformity, and microsphere distribution patterns. These measurements enable process optimization and quality assurance.

Statistical analysis of surface measurements helps identify trends and variations that may indicate process drift or formulation issues. Establishing control limits for key surface parameters ensures consistent product quality while enabling early detection of potential problems. Regular calibration and validation of measurement equipment maintains measurement accuracy and reliability.

Performance Testing and Validation

Comprehensive performance testing validates the effectiveness of Expancel microspheres in meeting specific surface texture requirements. Testing protocols typically include tactile assessment, gloss measurement, color stability evaluation, and durability testing under relevant environmental conditions. These tests provide confidence in long-term performance and help establish appropriate application limits.

Accelerated aging tests simulate long-term exposure conditions to evaluate surface stability and texture retention. Results from these tests inform warranty decisions and help establish maintenance recommendations for end users. Understanding performance limitations enables appropriate application selection and prevents field failures.

Future Developments and Innovations

Advanced Microsphere Technologies

Ongoing research and development efforts focus on creating next-generation Expancel microspheres with enhanced functionality and improved performance characteristics. Multi-shell technologies enable controlled release of multiple blowing agents, creating complex expansion profiles that produce sophisticated surface textures. These advanced systems offer unprecedented control over surface property development.

Smart microsphere systems incorporating responsive materials enable dynamic surface properties that adapt to environmental conditions or user inputs. Temperature-sensitive formulations can alter surface texture in response to thermal changes, while pH-responsive systems modify surface characteristics based on chemical exposure. These innovations open new possibilities for adaptive surface technologies.

Sustainable and Bio-Based Solutions

Environmental considerations drive development of sustainable microsphere technologies using renewable raw materials and environmentally friendly blowing agents. Bio-based shell materials derived from plant sources offer comparable performance while reducing environmental impact. These developments align with industry sustainability goals and regulatory requirements.

Recyclability improvements enable recovery and reuse of microsphere-enhanced materials, supporting circular economy principles. Chemical recycling processes can separate and recover intact microspheres for reuse in new applications, while mechanical recycling maintains sufficient surface properties for secondary applications. These capabilities expand the sustainable use of microsphere technologies.

FAQ

What temperature range activates Expancel microspheres for optimal surface texture enhancement

Expancel microspheres are available in various grades with activation temperatures ranging from 80°C to 220°C. The specific temperature range depends on the grade selected and the intended application. Lower temperature grades are suitable for thermosensitive substrates, while higher temperature grades work well in demanding processing environments. Proper temperature selection ensures optimal expansion and surface texture development while maintaining compatibility with existing manufacturing processes.

How does microsphere concentration affect the final surface texture characteristics

Microsphere concentration directly influences surface roughness, tactile properties, and visual appearance. Lower concentrations typically produce subtle texture effects suitable for premium surface finishes, while higher concentrations create more pronounced textures for functional applications. The optimal concentration depends on the desired surface properties, substrate characteristics, and processing conditions. Systematic testing helps determine the ideal concentration for specific applications and performance requirements.

Can Expancel microspheres be used in outdoor applications exposed to UV radiation

Yes, Expancel microspheres can be formulated for outdoor applications through proper selection of UV-stable shell materials and appropriate coating systems. UV resistance depends on the specific grade, protective coating formulation, and exposure conditions. Additional UV stabilizers and protective topcoats enhance long-term durability in demanding outdoor environments. Proper formulation and testing ensure adequate performance for the intended service life and environmental conditions.

What quality control measures ensure consistent surface texture results with microsphere applications

Effective quality control involves monitoring microsphere storage conditions, dispersion quality, processing temperatures, and final surface characteristics. Key control points include microsphere moisture content, mixing protocols, temperature profiles during expansion, and surface measurement validation. Statistical process control helps identify trends and variations that could affect surface quality. Regular calibration of measurement equipment and validation of test methods maintain measurement accuracy and support continuous improvement efforts.

Table of Contents

- Understanding Expandable Microsphere Technology

- Surface Texture Enhancement Mechanisms

- Industrial Applications and Benefits

- Processing and Integration Methods

- Quality Control and Performance Optimization

- Future Developments and Innovations

-

FAQ

- What temperature range activates Expancel microspheres for optimal surface texture enhancement

- How does microsphere concentration affect the final surface texture characteristics

- Can Expancel microspheres be used in outdoor applications exposed to UV radiation

- What quality control measures ensure consistent surface texture results with microsphere applications