The automotive industry continues to seek innovative materials that enhance performance while reducing weight and improving efficiency. Expandable microspheres have emerged as a revolutionary solution for manufacturers looking to create lighter, stronger, and more versatile components. These hollow plastic spheres expand when heated, creating unique properties that make them invaluable in modern vehicle production. Their ability to reduce density while maintaining structural integrity has positioned expandable microspheres as essential components in automotive material formulations.

Modern vehicle design demands materials that deliver exceptional performance across multiple parameters. Weight reduction remains a primary concern as manufacturers strive to improve fuel efficiency and meet stringent environmental regulations. Expandable microspheres offer a unique solution by creating cellular structures within materials, significantly reducing overall density without compromising mechanical properties. This technology has become increasingly important as automotive engineers balance performance requirements with sustainability goals.

Understanding the Science Behind Expandable Microspheres

Composition and Structure

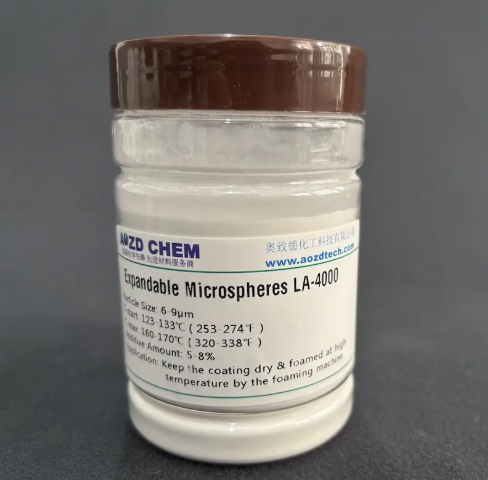

Expandable microspheres consist of a thermoplastic shell encapsulating a hydrocarbon blowing agent. When exposed to elevated temperatures during processing, the shell softens while the encapsulated gas expands, causing the spheres to increase in volume dramatically. This expansion process creates hollow structures that maintain their integrity while significantly reducing material density. The precise control over expansion temperature and volume makes these materials highly versatile for automotive applications.

The shell material typically consists of acrylonitrile or similar polymers that provide excellent thermal stability and chemical resistance. These properties ensure that expandable microspheres maintain their performance characteristics throughout the demanding automotive manufacturing process. The uniform spherical shape and controlled particle size distribution enable consistent processing and predictable material properties in final applications.

Expansion Mechanism and Control

Temperature control plays a crucial role in determining the final properties of materials containing expandable microspheres. The expansion begins at a specific activation temperature, allowing manufacturers to precisely time the expansion process during production. This controlled expansion enables the creation of materials with tailored density profiles and mechanical characteristics suited to specific automotive requirements.

Processing parameters such as heating rate, maximum temperature, and cooling conditions directly influence the final expanded structure. Engineers can manipulate these variables to achieve desired properties including density reduction, thermal insulation, and mechanical strength. This level of control makes expandable microspheres particularly valuable in complex automotive components requiring multiple performance characteristics.

Weight Reduction Benefits in Automotive Applications

Impact on Fuel Efficiency

Vehicle weight reduction directly correlates with improved fuel efficiency and reduced emissions. Every kilogram removed from a vehicle can result in measurable improvements in fuel consumption over the vehicle's lifetime. Expandable microspheres enable significant weight reduction in various automotive components without sacrificing performance or safety requirements. This weight reduction contributes to meeting increasingly stringent fuel economy standards while maintaining vehicle functionality.

The density reduction achieved through expandable microspheres can range from 10% to 50% depending on the application and expansion level. This substantial weight reduction translates to improved acceleration, handling, and braking performance. Additionally, reduced vehicle weight allows for smaller engines and more efficient powertrain systems, creating cascading benefits throughout the vehicle design.

Structural Integrity Maintenance

Despite significant density reduction, materials incorporating expandable microspheres maintain essential mechanical properties required for automotive applications. The cellular structure created during expansion provides excellent strength-to-weight ratios, ensuring components can withstand operational stresses while remaining lightweight. This balance between weight reduction and structural performance makes these materials ideal for critical automotive components.

Impact resistance and durability remain crucial considerations in automotive material selection. Expandable microspheres create closed-cell structures that absorb impact energy while maintaining component integrity. This energy absorption capability enhances passenger safety while reducing overall vehicle weight, demonstrating the multifaceted benefits of this technology.

Thermal Insulation Properties

Heat Management Systems

Thermal management represents a critical challenge in modern vehicles, particularly with the increasing integration of electronic systems and high-performance engines. Expandable microspheres provide excellent thermal insulation properties due to their cellular structure, which traps air and reduces heat transfer. This insulation capability helps maintain optimal operating temperatures for sensitive components while protecting passengers from excessive heat.

Under-hood applications benefit significantly from the thermal insulation properties of expandable microspheres. Components such as engine covers, exhaust shields, and electronic housings require materials that can withstand high temperatures while providing thermal protection. The expanded cellular structure effectively interrupts heat transfer pathways, creating efficient thermal barriers in compact packaging.

Acoustic Properties

Noise reduction has become increasingly important in automotive design as consumers demand quieter, more comfortable driving experiences. The cellular structure created by expandable microspheres provides excellent sound absorption and vibration damping properties. This acoustic performance enhancement contributes to improved cabin comfort and reduced noise pollution.

Engine compartment noise control benefits substantially from materials incorporating expandable microspheres. The hollow structures effectively absorb sound waves across multiple frequencies, reducing both airborne and structure-borne noise transmission. This acoustic control allows for more refined vehicle operation and enhanced passenger comfort throughout the driving experience.

Processing and Manufacturing Advantages

Injection Molding Applications

Injection molding processes benefit significantly from the incorporation of expandable microspheres in automotive component production. The spheres remain unexpanded during the initial mixing and injection phases, allowing for normal processing conditions. Expansion occurs during the heating phase of the molding cycle, creating lightweight parts with excellent surface finish and dimensional stability.

Cycle time reduction represents another significant advantage when using expandable microspheres in injection molding. The reduced material density allows for faster cooling and shorter overall cycle times, improving manufacturing efficiency. This efficiency gain translates to reduced production costs and increased throughput for automotive manufacturers while maintaining high-quality standards.

Compression Molding Benefits

Compression molding applications for automotive seals, gaskets, and structural components benefit from the unique properties of expandable microspheres. The controlled expansion during the molding process ensures complete mold filling while reducing material usage. This combination of material efficiency and performance enhancement makes compression molding with expandable microspheres highly attractive for automotive applications.

Part complexity and design flexibility increase when incorporating expandable microspheres into compression molding processes. The expansion capability allows for the creation of complex geometries and variable density profiles within single components. This design freedom enables automotive engineers to optimize part performance while simplifying assembly processes and reducing component count.

Specific Automotive Component Applications

Interior Components

Automotive interior components increasingly incorporate expandable microspheres to achieve lightweight construction while maintaining durability and aesthetic appeal. Dashboard components, door panels, and trim pieces benefit from the weight reduction and thermal insulation properties these materials provide. The cellular structure also contributes to improved tactile properties and reduced thermal conductivity for enhanced passenger comfort.

Seating systems represent another significant application area for expandable microspheres in automotive interiors. Foam formulations incorporating these materials achieve reduced weight while maintaining comfort and support characteristics. The improved thermal insulation properties also contribute to climate control efficiency and passenger comfort across varying environmental conditions.

Exterior Body Components

Exterior automotive components face demanding requirements for weather resistance, impact protection, and dimensional stability. Expandable microspheres enable the creation of lightweight body panels and structural components that meet these requirements while contributing to overall vehicle weight reduction. The closed-cell structure provides excellent moisture resistance and long-term durability.

Bumper systems and impact-absorbing components benefit significantly from the energy absorption properties of materials containing expandable microspheres. The cellular structure deforms predictably under impact, absorbing energy while protecting vehicle occupants and minimizing damage to other vehicle systems. This combination of lightweight construction and impact protection makes these materials ideal for safety-critical applications.

Quality Control and Testing Standards

Performance Validation Methods

Automotive applications require rigorous testing to ensure materials meet industry standards and performance requirements. Expandable microspheres undergo comprehensive evaluation including density measurements, thermal analysis, and mechanical testing to validate their performance characteristics. These testing protocols ensure consistent quality and reliability in demanding automotive environments.

Accelerated aging tests simulate long-term automotive exposure conditions including temperature cycling, humidity exposure, and chemical resistance. Materials incorporating expandable microspheres demonstrate excellent stability under these accelerated conditions, confirming their suitability for long-term automotive applications. This durability validation provides confidence for manufacturers and end-users alike.

Manufacturing Process Control

Process control during manufacturing ensures consistent expansion characteristics and final part quality when using expandable microspheres. Temperature monitoring, pressure control, and timing precision all contribute to achieving optimal expansion and material properties. Statistical process control methods help maintain quality consistency across production runs and different manufacturing facilities.

Quality assurance protocols include particle size analysis, expansion temperature verification, and chemical composition confirmation for incoming expandable microspheres. These controls ensure that materials meet specifications and will perform predictably during manufacturing processes. Traceability systems track material lots through production to enable rapid response to any quality issues that may arise.

Environmental and Sustainability Considerations

Lifecycle Impact Assessment

Environmental sustainability has become a driving force in automotive material selection, with manufacturers seeking solutions that reduce environmental impact throughout the vehicle lifecycle. Expandable microspheres contribute to sustainability goals through weight reduction, which improves fuel efficiency and reduces emissions over the vehicle's operational life. This operational benefit often outweighs the environmental cost of material production.

Recycling considerations play an important role in automotive material selection as manufacturers work to create more circular economy approaches. Materials containing expandable microspheres can be processed through conventional recycling streams, though the cellular structure may affect recycling efficiency. Research continues into optimizing recycling processes for these lightweight material systems.

Regulatory Compliance

Automotive materials must comply with numerous regulatory requirements related to safety, emissions, and environmental protection. Expandable microspheres meet these requirements while providing performance benefits that support regulatory compliance goals. Their contribution to weight reduction helps manufacturers meet fuel efficiency standards while maintaining safety requirements.

Chemical regulations governing automotive materials continue to evolve, requiring ongoing assessment of material compositions and emissions. Expandable microspheres have demonstrated compliance with current automotive chemical regulations while providing the performance benefits needed for modern vehicle design. This regulatory compliance ensures their continued availability for automotive applications.

Future Developments and Innovations

Advanced Material Formulations

Research and development efforts continue to improve the performance characteristics of expandable microspheres for automotive applications. New shell materials and blowing agents are being developed to extend operating temperature ranges and improve chemical resistance. These advances will enable new applications and enhanced performance in existing automotive uses.

Smart material concepts incorporating expandable microspheres are being explored for automotive applications requiring adaptive properties. These materials could respond to changing conditions by altering their cellular structure, providing variable insulation or mechanical properties as needed. Such innovations could revolutionize automotive material design and functionality.

Manufacturing Process Improvements

Manufacturing process innovations continue to improve the efficiency and effectiveness of incorporating expandable microspheres into automotive components. Advanced mixing techniques, precise temperature control, and automated quality monitoring systems enhance process reliability and product consistency. These improvements reduce manufacturing costs while maintaining high quality standards.

Digital manufacturing technologies including simulation and predictive modeling help optimize the use of expandable microspheres in automotive applications. These tools enable engineers to predict material behavior and optimize processing parameters before physical testing, reducing development time and costs. Such technological integration accelerates innovation and improves material utilization efficiency.

FAQ

What temperature range activates expandable microspheres in automotive processing

Expandable microspheres typically activate between 80°C and 200°C depending on the specific formulation and application requirements. This temperature range aligns well with standard automotive manufacturing processes including injection molding and compression molding. The precise activation temperature can be selected based on processing requirements and desired expansion characteristics for specific automotive components.

How much weight reduction can be achieved using expandable microspheres in automotive parts

Weight reduction typically ranges from 10% to 50% depending on the application, expansion level, and base material system. Interior components often achieve 20-30% weight reduction while maintaining required performance characteristics. Structural applications may have lower reduction levels to ensure safety requirements are met, while non-critical components can achieve higher weight reduction levels.

Are expandable microspheres compatible with recycled automotive materials

Expandable microspheres are generally compatible with recycled automotive materials, though some considerations apply to processing and performance. The cellular structure created during initial processing may affect subsequent recycling efficiency. However, materials containing expandable microspheres can typically be processed through conventional automotive recycling streams with appropriate process modifications.

What quality standards apply to expandable microspheres in automotive applications

Automotive applications require compliance with industry standards including ISO/TS 16949 quality management systems and specific material standards such as ASTM and ISO testing protocols. Additional requirements may include automotive OEM specifications, chemical compliance regulations, and safety standards. Suppliers must demonstrate consistent quality through statistical process control and comprehensive testing protocols throughout the supply chain.

Table of Contents

- Understanding the Science Behind Expandable Microspheres

- Weight Reduction Benefits in Automotive Applications

- Thermal Insulation Properties

- Processing and Manufacturing Advantages

- Specific Automotive Component Applications

- Quality Control and Testing Standards

- Environmental and Sustainability Considerations

- Future Developments and Innovations

-

FAQ

- What temperature range activates expandable microspheres in automotive processing

- How much weight reduction can be achieved using expandable microspheres in automotive parts

- Are expandable microspheres compatible with recycled automotive materials

- What quality standards apply to expandable microspheres in automotive applications