customized chemical additives

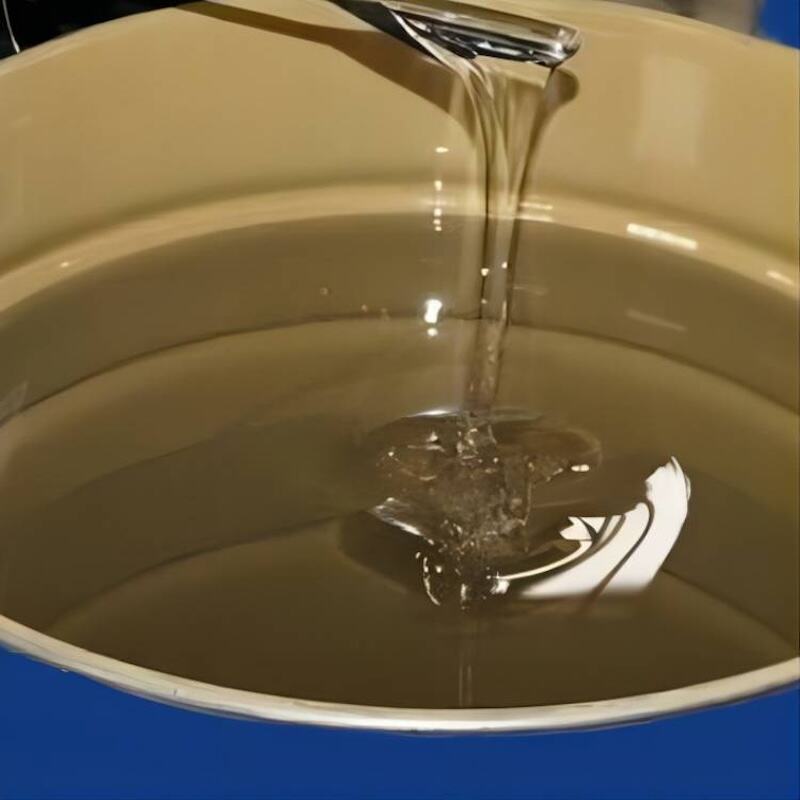

Customized chemical additives represent a sophisticated solution in modern industrial processes, offering tailored formulations designed to meet specific manufacturing requirements. These specialized compounds are engineered to enhance product performance, improve process efficiency, and solve unique industrial challenges. The additives undergo rigorous development processes, incorporating advanced chemical engineering principles to ensure optimal functionality in diverse applications. From improving material properties to enhancing production efficiency, these additives serve multiple purposes across various industries. They can modify viscosity, enhance stability, improve dispersion, and provide specific functional properties to end products. The technology behind these customized solutions involves precise molecular design, careful selection of raw materials, and sophisticated blending techniques to achieve desired characteristics. Applications span across multiple sectors, including plastics manufacturing, coating industries, construction materials, and specialized industrial processes. These additives can be fine-tuned to operate under specific conditions, whether it's extreme temperatures, high pressure, or challenging chemical environments. The customization process involves detailed analysis of client requirements, laboratory testing, and optimization to ensure the additive perfectly matches the intended application.