expandable microspheres made in china

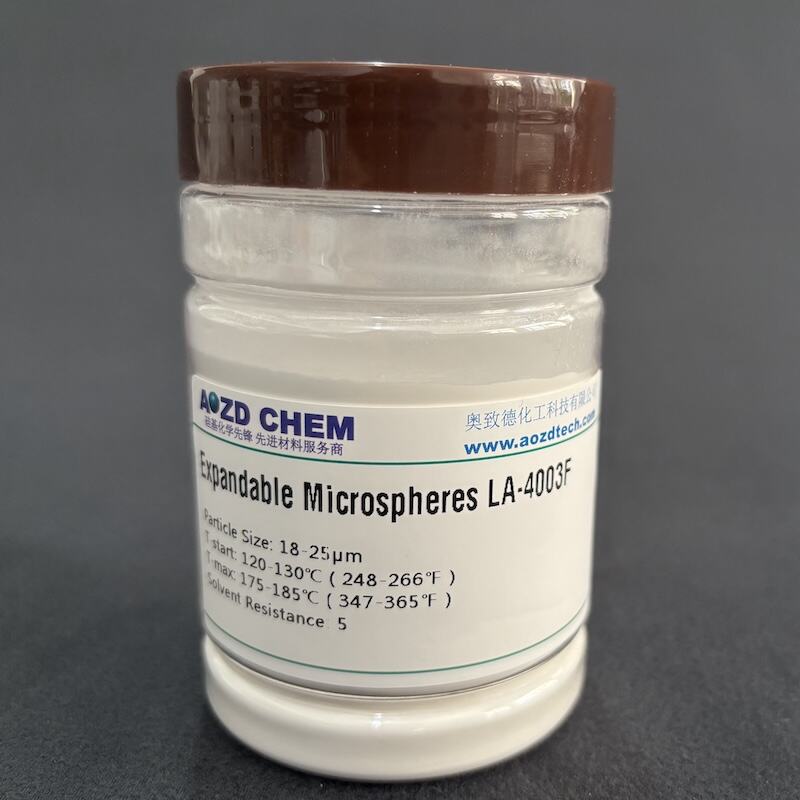

Expandable microspheres made in China represent a groundbreaking advancement in polymer technology, offering versatile solutions across multiple industries. These microscopic spheres consist of a thermoplastic shell encapsulating a hydrocarbon blowing agent, engineered to expand significantly when exposed to heat. Through advanced manufacturing processes, Chinese manufacturers have developed these microspheres to achieve expansion ratios of up to 40 times their original size while maintaining structural integrity. The microspheres exhibit excellent temperature resistance, ranging from -30°C to 120°C, making them suitable for diverse applications. They provide exceptional lightweight properties, reducing material density by up to 65% while enhancing thermal insulation capabilities. The manufacturing process employs cutting-edge suspension polymerization techniques, ensuring consistent particle size distribution and expansion characteristics. These microspheres are available in various grades, with customizable expansion temperatures ranging from 80°C to 200°C, catering to specific application requirements. They find extensive use in automotive parts, construction materials, printing inks, and various polymer compounds, where weight reduction and thermal properties are crucial.