highperformance leather additives

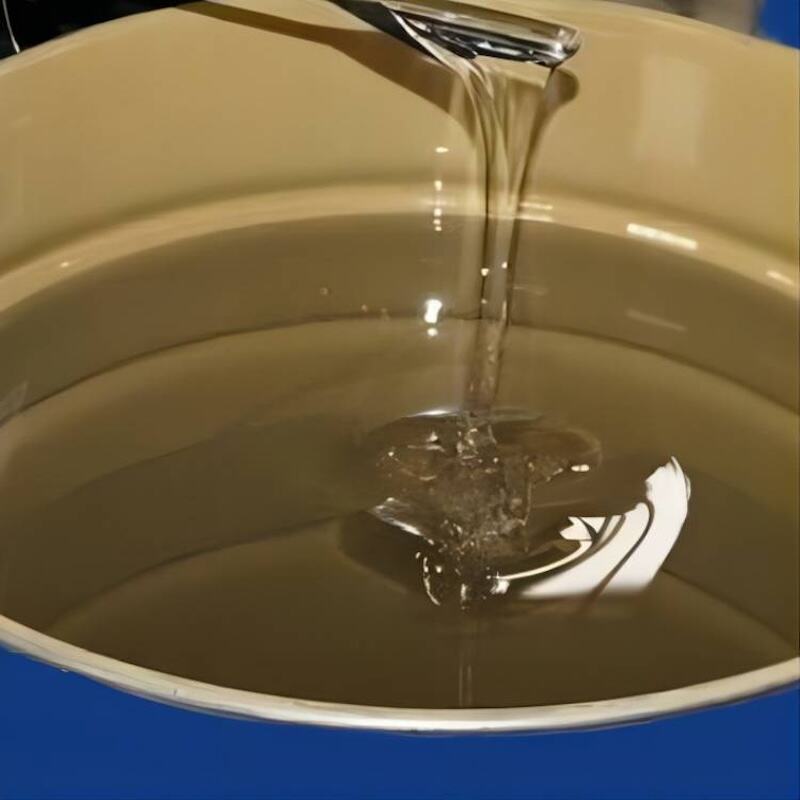

High performance leather additives represent cutting edge solutions in modern leather manufacturing, encompassing a diverse range of chemical compounds specifically engineered to enhance leather quality and processing efficiency. These advanced formulations serve multiple critical functions throughout the leather production cycle, from initial processing to final finishing. The additives include specialized fatliquors, retanning agents, and finishing chemicals that work synergistically to improve leather characteristics. They effectively enhance water resistance, increase tensile strength, and optimize the leather's physical properties while ensuring consistent quality across production batches. These innovative additives are particularly notable for their ability to reduce environmental impact through improved efficiency and reduced chemical consumption. The technology behind these additives incorporates advanced polymer science and green chemistry principles, resulting in products that meet both performance requirements and environmental standards. Applications span across various leather sectors, including automotive upholstery, luxury goods, footwear, and technical leather products. The additives are designed to work effectively under different processing conditions and can be customized to meet specific end-use requirements, making them invaluable in modern leather manufacturing.