highquality additives manufacturers

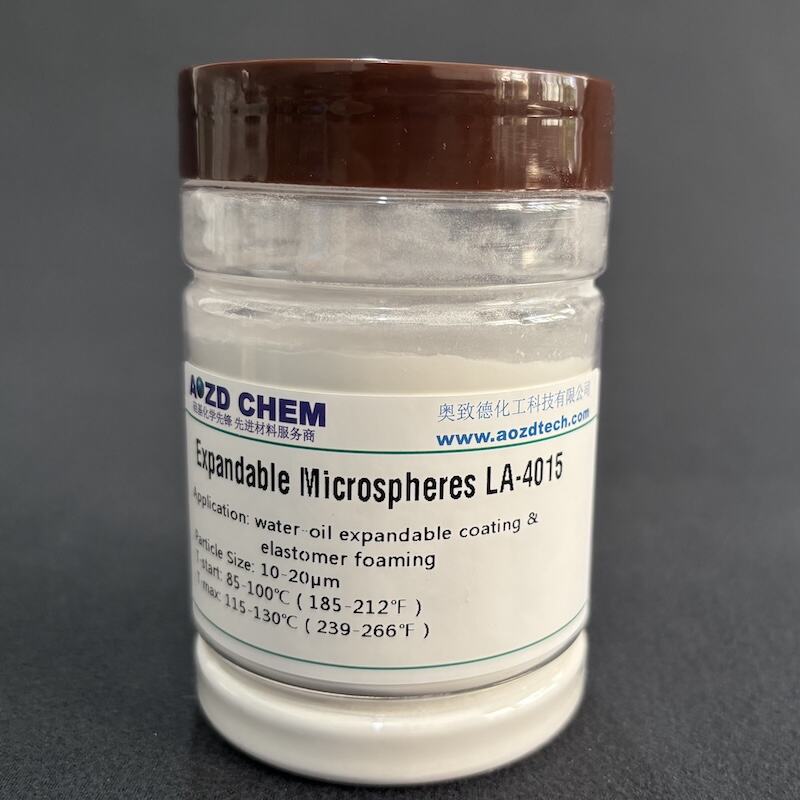

High quality additives manufacturers represent a crucial segment of the chemical industry, specializing in the development, production, and distribution of premium chemical compounds that enhance various products and processes. These manufacturers employ state of the art facilities and advanced research laboratories to create additives that meet stringent quality standards and regulatory requirements. Their product portfolio typically includes performance enhancing substances for industries ranging from food and beverages to construction materials and industrial processes. These manufacturers utilize cutting edge technology and precise quality control systems to ensure consistency and reliability in their products. They maintain sophisticated testing facilities for continuous product development and improvement, while also offering customized solutions to meet specific client requirements. The manufacturing processes incorporate automation and digital monitoring systems to maintain precise control over production parameters, ensuring uniform quality across batches. These facilities often operate under international quality management systems such as ISO 9001, with dedicated quality assurance teams overseeing every aspect of production. Additionally, these manufacturers typically maintain extensive research and development departments focused on innovation and developing new additive solutions to address emerging market needs.