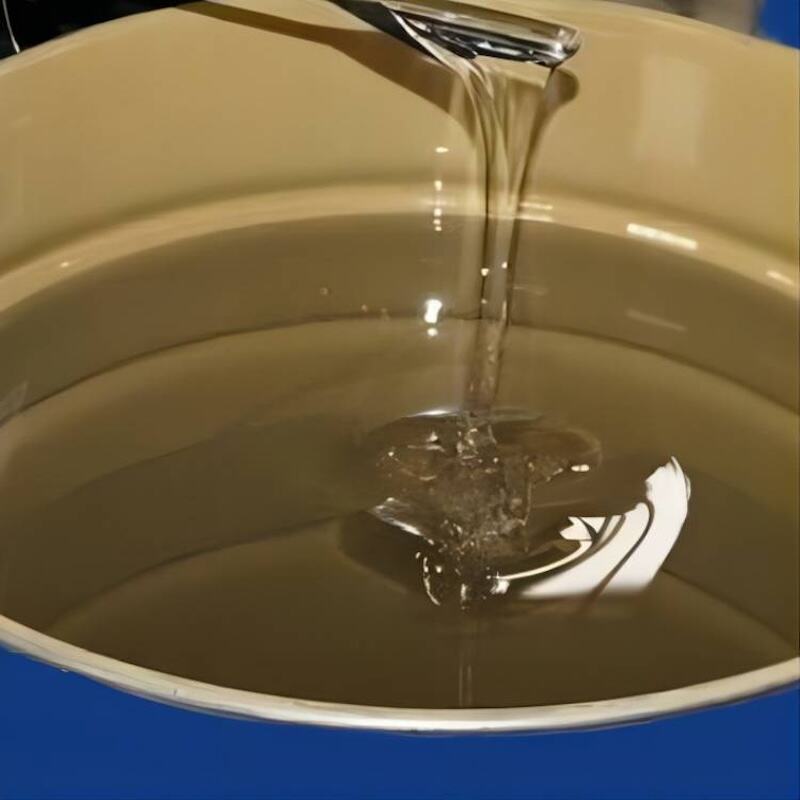

spinning oil made in china

Spinning oil made in China represents a significant advancement in textile manufacturing technology, offering optimal performance for yarn production processes. This specialized lubricant is specifically engineered to reduce friction between fibers and mechanical components during the spinning process, ensuring smooth operation and enhanced productivity. The formulation comprises carefully selected base oils and advanced additives that provide excellent fiber cohesion, antistatic properties, and heat resistance. These oils maintain consistent viscosity across varying temperatures and speeds, crucial for maintaining yarn quality. Chinese manufacturers have developed sophisticated refining processes that ensure high purity levels and minimal volatile organic compounds, making the spinning oil environmentally friendly and worker-safe. The product demonstrates remarkable stability during high speed spinning operations, preventing fiber breakage and reducing machine wear. Additionally, these oils feature superior emulsification properties, allowing easy washing from finished yarns without leaving residues. Modern Chinese spinning oils incorporate advanced anti misting technology, reducing oil mist formation in the workplace and improving operational safety. The product's versatility makes it suitable for various fiber types, including natural and synthetic materials, while its cost effectiveness has made it increasingly popular in global textile manufacturing.