Introduction to Expandable Microspheres and Material Quality

What Are Expandable Microspheres

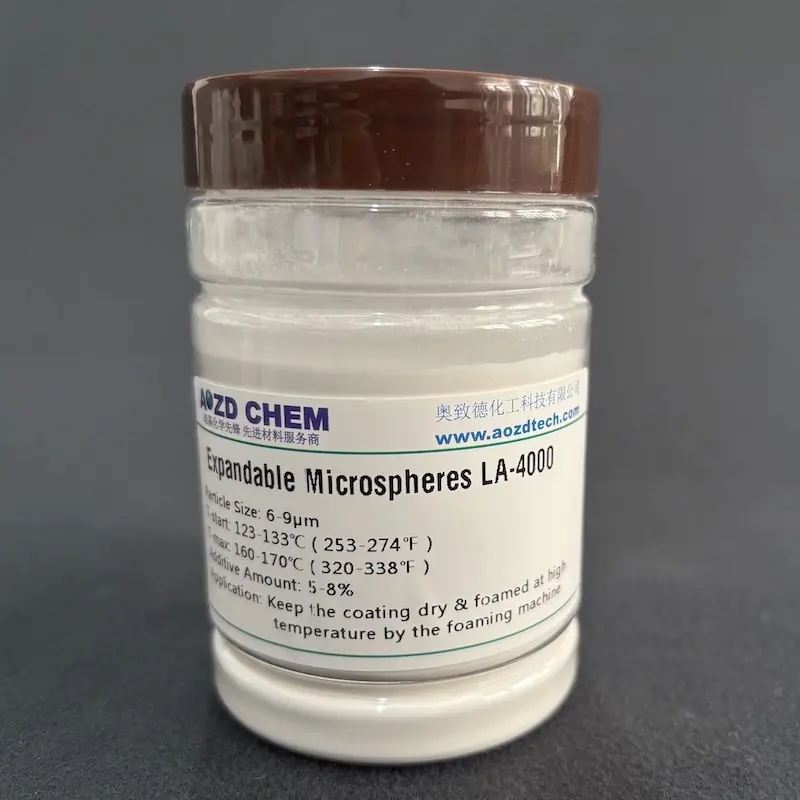

Expandable microspheres consist of tiny hollow polymer balls packed with gas inside. When heated, they actually expand in size. Most of these little spheres measure somewhere between about 10 and 100 micrometers across, though exact sizes can vary depending on application needs. The materials world has seen growing interest in these microspheres lately across different fields such as cars, buildings, and everyday products because they help cut down material weight while boosting insulation properties. What makes them so useful is their light weight and low density characteristics. This allows manufacturers to create composite materials that work well without being too heavy or expensive. Plus, the insulation benefits matter a lot for things like electronic gadgets where keeping components cool is important, and for packaging where protecting contents from temperature changes remains critical.

Role in Modern Material Science

Expandable microspheres have become pretty important in creating better materials for various industries including aerospace and cars. These tiny spheres actually improve how products perform by making them stronger mechanically and helping cut down on weight significantly. Take the automotive industry for example where manufacturers put these microspheres into different parts so vehicles weigh less without sacrificing strength, which naturally leads to better gas mileage. Various tests and experiments show that these little balls really do boost things like tensile strength and heat resistance when mixed into plastics and other polymers. The ability to create lighter yet tougher products matters a lot in today's market where companies need to meet strict rules about energy usage and carbon output while still delivering quality goods that last.

Lightweight and Durable Materials Enabled by Expandable Microspheres

Automotive Industry Innovations

Car makers are turning to something called expandable microspheres to make their vehicles lighter, and this helps cars burn less fuel. When they put these tiny spheres into parts such as bumpers, dashboards, even some plastic components throughout the car body, manufacturers find they can cut down on overall weight while still keeping everything strong enough. Some studies show that when companies start using these microspheres in their designs, they often manage around a 20% drop in total vehicle weight. That means better gas mileage for drivers and fewer harmful emissions going into the atmosphere. With all the government rules pushing for cleaner transportation options right now, this kind of innovation gives automakers a real fighting chance against those tough environmental standards.

Construction Material Advancements

Expandable microspheres are changing the game in construction these days, especially when it comes to improving stuff like concrete and insulation boards. When builders mix these tiny spheres into their materials, they get better insulation because heat doesn't pass through so easily. That means buildings stay warmer in winter and cooler in summer without needing extra heating or cooling. What's really cool is that these microspheres actually make materials stronger while keeping them light. Think about it - stronger walls that don't weigh a ton? That's pretty much every contractor's dream. The construction industry has been pushing for lighter materials for years now, as seen in all those ASTM standards we keep hearing about. No wonder more and more architects specify microsphere-infused products on their projects. It just makes sense for both the environment and the bottom line.

These innovations across automotive and construction sectors underscore the pivotal role expandable microspheres play in creating lightweight, durable, and energy-efficient materials that meet industry demands for performance and sustainability.

Improved Thermal and Acoustic Insulation Properties

Thermal Resistance in Building Materials

Expandable microspheres make a big difference in how well building materials insulate against heat, helping cut down on energy costs across the construction sector. Basically, these tiny spheres have thermoplastic walls filled with gas inside, and they puff up when exposed to heat during manufacturing processes. What happens next is pretty cool – as they expand, they form lots of tiny air pockets within the material matrix. These pockets act as barriers to heat flow, making things like concrete blocks and insulation panels much better at keeping temperatures stable. We've seen real results from using them in insulation products too. One particular application reduced heat loss through walls by around 30% according to testing data, which translates to major savings on HVAC systems over time. With sustainability becoming increasingly important in architecture circles, incorporating these microspheres represents both an environmentally friendly choice and smart cost management strategy for builders looking ahead.

Soundproofing Solutions for Vehicles

Expandable microspheres have become quite useful in cars for absorbing sounds and making the ride quieter for passengers. When manufacturers put these tiny spheres into parts such as dashboard areas and underneath panels, they cut down on road noise pretty effectively. What makes this technology interesting is that it creates materials which weigh less while still doing a good job at stopping unwanted noises from vibrating through the cabin. Some studies show that vehicles equipped with this tech can be up to half as noisy as those without, giving drivers and passengers a much calmer atmosphere during their journeys. Beyond just reducing noise, these microspheres help make cars lighter overall, which means better fuel efficiency and lower emissions too.

Enhanced Aesthetic Qualities Through Microsphere Integration

Smooth Textures in Consumer Goods

Products containing expandable microspheres tend to look and feel better overall, especially when it comes to how they touch our skin or hands. When manufacturers add these tiny spheres into their formulas, the resulting items have smoother finishes and nicer textures across the board. That's why we see them so much in makeup and skincare products these days. Think about those fancy face creams that glide on effortlessly without leaving residue behind. For household items too, companies incorporate microspheres to create surfaces that just feel good to handle, which makes people want to buy them more often. Recent market research shows consumers are increasingly drawn to products that simply feel nicer to touch, and texture has become one of the main ways brands stand out from competitors on store shelves.

Matte Finishes in Industrial Coatings

Expandable microspheres help manufacturers achieve those coveted matte finishes in industrial coatings, giving products both better looks and practical advantages. What makes these tiny spheres so effective? They create a consistent surface texture that doesn't glare under lighting conditions, which means coatings look nicer on the eye while standing up to wear and tear longer than glossy alternatives. The automotive sector has really taken notice of this technology, as well as electronics manufacturers who want their devices to have that professional, no-glare finish consumers find attractive. Real-world testing shows coated parts not only look better but last significantly longer too. Many companies report happier customers when they switch to microsphere-based coatings, which makes sense given how much first impressions matter in competitive markets.

Cost Efficiency and Sustainability Benefits

Reducing Raw Material Consumption

Adding expandable microspheres to product formulas cuts down on how much raw stuff companies need to buy. When heated, these tiny balls swell up to about 60 times bigger than they were originally. That means factories can get away with using way less material but still cover the same area and work just as well. The money savings are pretty impressive too. Companies report saving around 15% on materials when switching to microspheres, which definitely helps trim those production bills. What makes this technology so appealing is that it works across different scales and applications. From coatings to plastics, manufacturers find themselves reaching for microspheres more often as they try to cut waste without compromising quality.

Eco-Friendly Manufacturing Processes

When it comes to sustainability, expandable microspheres bring quite a few benefits to the table, especially when looking at how they cut down on energy needed during manufacturing. Since these tiny spheres require fewer raw materials overall, this naturally leads to less energy being consumed throughout production while also shrinking the negative effects on our environment. According to various life cycle assessments, products made with microspheres tend to leave behind about 25% smaller carbon footprints than what we see from conventional manufacturing techniques. One recent industry report actually pointed out that using these little guys helps manufacturers produce goods in a greener way simply because there's just not as much waste generated and energy demands drop significantly too. For businesses genuinely interested in going green without sacrificing quality or performance, incorporating expandable microspheres into their processes makes sense both environmentally and economically speaking.

FAQ Section

What industries commonly use expandable microspheres?

Expandable microspheres are widely used in industries such as automotive, construction, consumer goods, aerospace, and electronics.

How do expandable microspheres contribute to energy efficiency?

Expandable microspheres enhance thermal insulation properties, reduce weight, and lower material usage, leading to increased energy efficiency in building materials and vehicle components.

Are expandable microspheres environmentally friendly?

Yes, they reduce raw material consumption, decrease energy usage in production, and lower the carbon footprint, making them more environmentally friendly than traditional materials.

Do expandable microspheres improve product aesthetics?

Yes, they enhance the texture and appearance of consumer goods and provide matte finishes in industrial coatings.