Crescens Petition pro Materialibus Levis et Durabilibus

Materiae leves in multis diversis sectoribus, praesertim in industria automobilistica et aerospaciali, populores fiunt. Hoc magis ex desiderio melioris aedilis conservationis et reductionis noxiarum emissionum oritur. Cum vehicula levia fiunt, minus gasolei adurunt et pauciores noxias emissiones creant, quae regulas severas ambientales transire iuvat simulque monet super gasoleo salvam. Idem principium etiam ad aeronaves attinet. Cibari aerei quaerunt modos leviare aedificia sua quia singulis libris ablativis verum pecuniae in gasoleo super tempus salvatur. Tamquam autem manufactores automobilorum quam aedifices aeroplanorum procedunt, crescit interesse in inveniendis materiae quae leves sint, tamen firmitatem et durabilitatem praebere debeant.

Cupido pro materialibus, qui gravem vim et asperas conditiones ambientales sustineant, numquam fuit maior, quod progressus mirabiles in scientia materialis movit. Omnes societates in multis sectoribus volunt res quae non solum vim physicam patiantur, sed etiam rictum et extremas temperaturas ferant. Nunc omnis generis nova incrementa videmus, inter quae syntactica spuma et illae expandable Microspheres quae levitatem cum gravi durabilitate iungunt. Ad fabricantes, quae in omnibus ab aerospacialibus componentibus ad subaquatica instrumenta operantur, haec materiae significat eos posse structuras integras servare dum operationem reliquam obtinent etiam cum conditiones asperae fiunt. Impetus longe extendit praeter solum meliores res faciendas: re vera mutat modum, quo ingeniores problemata schemationis in constructione, transporto et industria manufacturaria tractant.

Intellegentia de Foamed Microsphaeras: Structura et Principales Beneficia

Compositio et Fabricatio de Expandable Microspheres

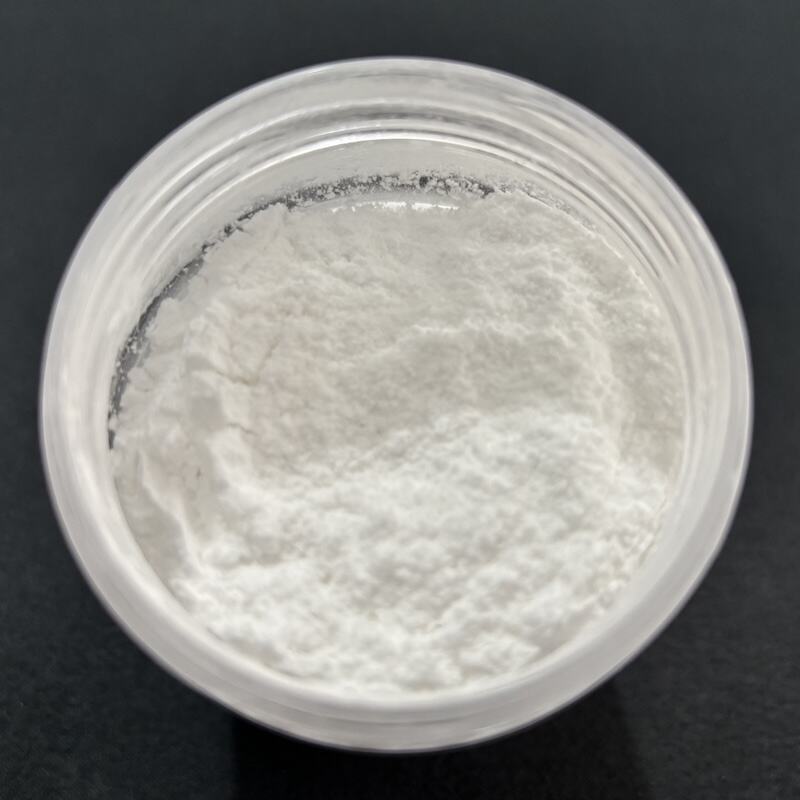

Microsphaerae spongiosae, quae expandibiles saepe vocantur, praecipue ex polymers constant quae in productione intumescunt ut formae illarum globulorum cavorum fiant. Quod evenit est ut hi materiae expandantur cum calefiunt, quod eos valde leves reddit. Hoc est cur bene operantur in variis locis ubi pondera momenti sunt. Ad eas fabricandas, manufactores saepe methodis utuntur velut polymerizatio in suspensione vel solventia simpliciter evanescunt. Mirabile sane in his processibus est - multum emendari et adaptari possunt. Itaque microsphaerae ad mensuram factae sunt pro necessitatibus praecipuis, sive de materia isolatoria ad aedificia sive de componentibus in partibus automotiveis agitur. Adaptabilitas porro possibilitates aperit in variis sectoribus a constructione ad aerospatialem scientiam.

Parva Densitas et Alta Elasticitas Proprietates

Microsphaerae expansae densitatem valde infimam habent, ideoque in pluribus industriae populares fiunt, ubi pondera productorum minuenda sunt, tamen stabilitas sufficientis retinetur. In exemplis, in automotive et generibus domesticis: componentes leves meliorem aedentiae oeconomicae et meliorem perficientiam generalem significare possunt. Curiosum tamen est quomodo haec minuta sphaerae post compressionem revertuntur. Etiam ictus bene absorbebant cum pressione continua per tempus applicata. Haec sunt quae eas in locis ut tabularia automobilorum vel in munitis involucris utilis facit, ubi res ictus sustinere sed simul flexibilis manere debet. Fabricatores incipiunt sentire quam versatiles hi materiae in creandis productis quae et vim et aliquam flexibilitatem requirunt esse possint.

Capacitates Isolationis Thermicae et Acusticae

Microsphaerae spongiosae valde optime functionant pro caeli conservatorii ratione, quod multum inclusae aeris intra minutas sphaeras continent. Aedificatores arctissime eas in parietibus et tectis utuntur, quod domos tepidiores manere in hyeme dum censurae calefaciendi minuuntur. Artifex carrorum recente in his materiae in tabulatis et pannelis ianuam adiunctis, quod pondus salvat sine commodo detrimento. Aliud mirabile de his microsphaeris est quomodo undas sonicas absorbent. Cum ad materiae compositae adduntur, significantur sonos itineris in vehiculis minui. Homines qui in vehiculis hac technologia usi sunt silentium loculi notant prae modelis antiquioribus. Cum utraque ratione temperaturae et reductionis soni in una materia coniuncta sint, mirum non est quare tam multi artes usi microsphaeris spongiosis aedificationibus ad manufacturam instrumentorum industrialium.

Innovatio Design Automotivum: A Interioribus ad Performantiam

Leves Tabeleae Internae et Solutiones Ornatus

Additio microsphaerarum ad interna automobilorum permittit notabiliter minuere pondus vehiculi, quod efficit ut automobilia compertum habeant meliora. Materia haec levis est, sed tamen satis robusta ad fabricandos tabularum internarum partes sine damno qualitatis aut integritatis structurae. Curiosum est quoque quomodo microsphaerae hae creare possunt quasdam elegantes optiones ornatuum ad emendationem designi cabinorum, dum tamen installationem simplicem retinent. Ante omnia, ornatuum integritas bene resistit cotidiano usu et abusu, et manet firma etiam cum ad diversa temperata et humiditatis gradus in vehiculis exposita sint. Hae conjunctio decori et utilitatis praebet quod nunc fabricantibus opus est.

Strumenta Reducens Sonos Utiendo Microsphaeras Fomatas

Fabricatores automobilorum nunc coepisse sunt uti tectis mixtis cum microsphaeris spongis ad riducendam strepitum viarum, ita ut interiores automobilorum multo silentiores sint quam ante. Effectus insulandi sonis valde importat apud conductores qui pacem cupiunt dum it per vias, quia strepitum magnae viae et alia externa impedimenta intercludit. Quod mirum est, eadem tecta etiam mirabiliter adiuvant temperaturam in vehiculis regere, servans eas frigidiores aestate sine systematis aeris condicionis exaggerata operatione. Quamquam aliqui dubitare possunt num haec omnia necessariam rem extruere, multi tamen automobilorum fabricatores utilitatem in auditu minuendo coniuncto cum climatis moderando videre, quod ultimum profectum qualitatem itineris meliorem efficit simulque in futuro potest vim acquirere.

Componentes Structurales ad Auctandam Efficientiam Combustibilis

Additio microsphaerarum ad partes automobilis eas leviores reddit, dum tamen satis validas manere pro conditionibus quotidiano usui. Levitas minor significat automobilia minus gasolei consumere quia minus laborare debent ut moveantur, dum tamen conductores protectionem plenam obtinent quam ex collisionibus necessariam est. Aestimatio gasolei facta est magna cum difficultate nuper propter crescentes pretios gasolei et strictiores leges de emissionibus. Fabricatores automobiliorum valde creativi nunc de materialibus. Microsphaerae offerunt aliquid praecipui per foramina aerea intra materiam quae eas leviores et robustiores reddunt. Hoc permittit fabricatoribus aedificare vehiculos meliores pro ambiente sine qualitatis detrimento aut satisfactione conductoris, quod omnino quod consummatores nunc volunt dum cura pro ambiente crescit una cum amore pro machinis validis.

Transmutatio Technologiae Calceamentorum: Incrementum Midsole Praeceptricium

Systemata Cushioning Midsole cum Retorno Energiae

Additio microsphaerarum ad intersolas calceamentorum ludum mutat pro calceamentis sportivis, eos meliorem in cedulis et reactione praebens cum pedes ad terram feriunt. Hae minuti foramina aerea intra sphaeras vim contusionis longe melius absorbent quam materiae antiquae, ita pedes post longas cursiones vel exercitationes graves non tantum defatigantur. Compatibilitas etiam multum aucta est, hoc est homines diutius ferre possunt sine dolore. Nunc videmus manufactores cotidie formulas microsphaerarum mutare. Aliquae societates etiam cum formis et magnitudinibus variis experientur ad curandos pedis locos speciales. Haec innovatio non iam solum pro athletis professionalibus est, sed etiam homines vulgares qui horas in pedibus agunt differentiam in vestitu quotidiano sentiunt.

Supportio Customizabilis Per Ingenium Sphaerularum

Sphaerae expansae novas possibilitates aperuerunt ad creandas mediasolas quae congruunt cum singulis athletae necessitatibus. Adapatio ad variabiles necessitates facta est ad necessitatem fabricorum qui ad diversa exercitia et pedum formas in productis suis respondere volunt, quod natura basim clientium amplificat. Marcae quae huiusmodi materiales elaboratos utuntur calceos cum systematibus deprehensi offerre possunt quae secundum varias vires impactionis durante exercitatione accommodant, meliorem stabilitatem et operam generalem efficiens. Quod hanc technologiam praecipue notabilem reddit est modus quo comoditatem cum idoneis deprehenionis structuris aequat, quod athletae e variis regionibus postulant quotiens se physice urgeant die post diem.

Principales Vantagii Promovendo Adoptionem Trans-Industrialis

Reductio Ponderis Sine Compromissione Structurae

Additio microsphaerarum ad manufacturam societatibus re vera auxilio est, cum opus est remissione ponderis nec tamen firmitate producti finalis immutata. Cogita de automobilis et aeroplanis, ubi manufactores semper quaerunt modos remittendi pondus nec tamen vim aut durabilitatem minuendi. Vehicula leviora minus combustibile consumunt, quod adiuvat emissionem minuere et pecuniam super tempus conservare. Praeterea, pauciores res adhibere significat minus inutilis. Pro mercaturis, hoc efficit minores sumptus, quia pauciora prima elementa sunt ad eundem numerum mercium creandas. Saepius qui hanc technologiam sequuntur ante alios se inveniunt, quia hodie homines optant optiones viridiores et meliorem actuationem e mercimoniis suis.

Flexibilitas in Applicationibus Scientiae Materialium

Microsphaerae spumatae in scientia materialium bene prospere sunt, quia optime in omnibus rebus adhibentur, quas homines antea non cogitaverant. Nunc ubique conspiciuntur, a materia isolatoria aedificiorum usque ad fabricam ultimae generationis electronicae. Quae facit ut haec minuta sphaerae sint speciales, est flexibilitas eorum. Fabricatores proprietates eas mutare possunt, ut exacte ad res diversarum artium aptentur. Exempli gratia, additio eorum ad parietes aedificiorum augmentat retentionem caloris, dum in partes automobilorum incorporatae tutelam a collisionibus meliorem. Haec minuta bullae inveniuntur in omnibus, a proiectis domi instituendis usque ad apparatus medicinales subtilissimos. Hac de causa multi ingenarii eas putant fundamenta necessaria ad aedificanda nova technologia in variis campis hodie.

Fabricationes Oeconomicae

Microsphaerae spongatae remitteunt curas manufacturae, praebendo negotiis praeclarum beneficium ad pecuniam conservandam. Cum manufactores rationem productionis harum exiguarum sphaerarum mutant, minorem materiam primam et energiam consumunt, qua ex causa minores expensae mensae incumbunt sine qualitatis detrimento. Praeterea, cum manufactura viridis iam in omnibus artibus florere incipit, etiam hi globuli minuti adiuvant ad remissionem inutilis materiae et carbonis footprints. Negotia ea propter amant, quod simul productionem pecuniose moderatam et in libris de sustentatione bonam speciem obtinent. Eventus, quod negotiis iam fieri viridem sine inpendio magno explicat cur tam multi fabricae hanc technologiam nuper adsumpserint.

Conclusio: Futurum Latus Technologiae Microsphaerarum

Porro prospectante, microsphaerae in technologia habent futurum splendidum, praesertim quia microsphaerae expansae interdum magis important in novis rebus materialibus. Industriae semper quaerunt materiae leviorem sed tamen solidiorem, et haec postulatio celeriter crescit in aedificiis, aerospacii, etiam in mercatis productorum ad consumptorem. Corpora desiderant res quae bene operentur absque rerum amissione, itaque microsphaerae expansae apte in hoc schemate insident. Haec parva sphaerae accommodari possunt ad multas finalitates, quae eos valde utiles reddit ad solutiones sustinendas creandas. Ab insolatione materiae ad composita structurae, eorum facultas ad satisfaciendum variis industriae postulationibus dum tamen impetus ambientalis minuitur, significat corpora in variis campis eos amplius sequuturum esse dum progredimur.

Sectio FAQ

Quid sunt sphaerae foamatae?

Sphaerae foamatae sunt leves, expandibiles sphaerae polymericae usae in variis industriis pro applicationibus requirentibus pondus redactum et durabilitatem auctam.

Quomodo sphaerae foamatae augeunt design automotorium?

Ad contribuendum ad diminutionem ponderis in panelibus interioribus et ad praebenda facultates soundproofing et regulationis temperatura, meliorem efficientiam vehiculi praebentes.

Possunt sphaerae micrae foemata utilia esse in technologia calceamentorum?

Ita, easdem midsoles meliores faciunt propter maius molliorem, restitutionem energiae et supportum personalizatum, meliorem performance calceamentorum athleticorum praebentes.

Index Rerum

- Crescens Petition pro Materialibus Levis et Durabilibus

- Intellegentia de Foamed Microsphaeras: Structura et Principales Beneficia

- Innovatio Design Automotivum: A Interioribus ad Performantiam

- Transmutatio Technologiae Calceamentorum: Incrementum Midsole Praeceptricium

- Principales Vantagii Promovendo Adoptionem Trans-Industrialis

- Conclusio: Futurum Latus Technologiae Microsphaerarum

- Sectio FAQ