leather finishing additives

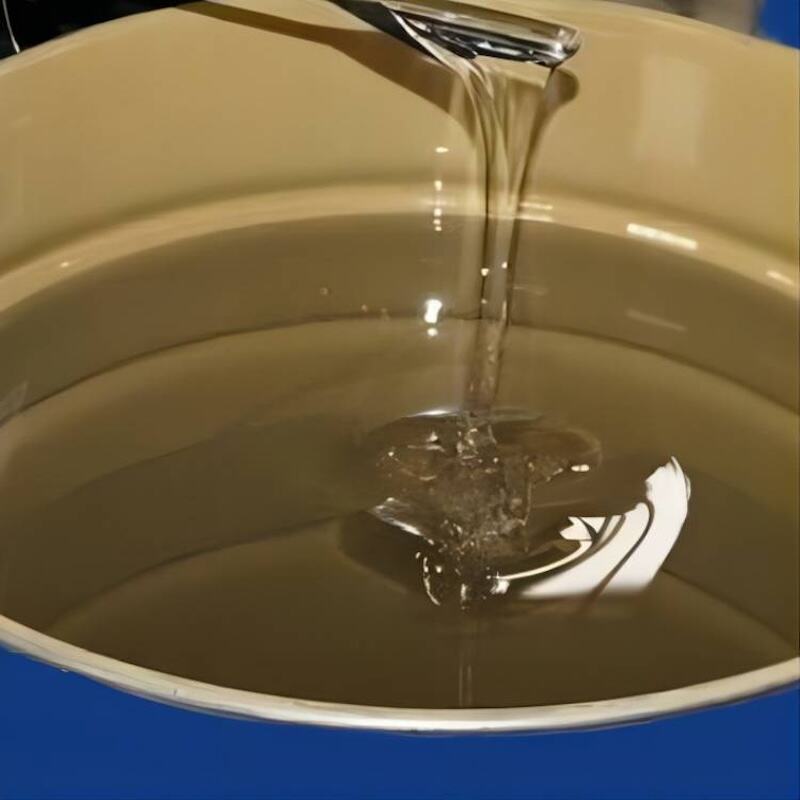

Leather finishing additives are specialized chemical compounds designed to enhance the quality, durability, and aesthetic appeal of leather products. These essential components play a crucial role in the final stages of leather processing, providing surface protection, color enhancement, and specific performance characteristics. The additives encompass a wide range of products including resins, waxes, pigments, and performance enhancers that work together to create desired leather properties. They are formulated to improve various aspects such as water resistance, scratch resistance, UV protection, and overall durability of the leather surface. These additives also contribute to the leather's feel and appearance, helping achieve specific textures, glossiness levels, and tactile properties. In industrial applications, leather finishing additives are carefully selected based on the intended end-use of the leather, whether it's for automotive upholstery, furniture, fashion accessories, or footwear. Modern leather finishing additives are developed with environmental considerations in mind, incorporating eco-friendly components and sustainable processing methods. The technology behind these additives continues to evolve, offering improved performance characteristics while meeting stringent environmental regulations and industry standards.