Selecting High-End Leather Feel Modifier for Superior Luxury Finishes

Choosing the right High-End Leather Feel Modifier is essential for manufacturers who want to deliver premium texture, long-lasting performance, and a luxurious hand-feel to their finished products. A High-End Leather Feel Modifier directly influences how consumers perceive the quality of leather goods such as handbags, footwear, automotive interiors, and premium upholstery. Because the feel and surface refinement of luxury materials play such a critical role in brand positioning, selecting a suitable High-End Leather Feel Modifier becomes a strategic decision that impacts both product performance and market appeal. In the luxury industry, everything from smoothness to softness and naturalness matters, and this specialized modifier helps manufacturers achieve a refined finish aligned with high-end expectations. With increasing global demand for elevated tactile experiences, mastering the selection and application of the right High-End Leather Feel Modifier is now more important than ever.

Understanding High-End Leather Feel Modifier

Definition of High-End Leather Feel Modifier

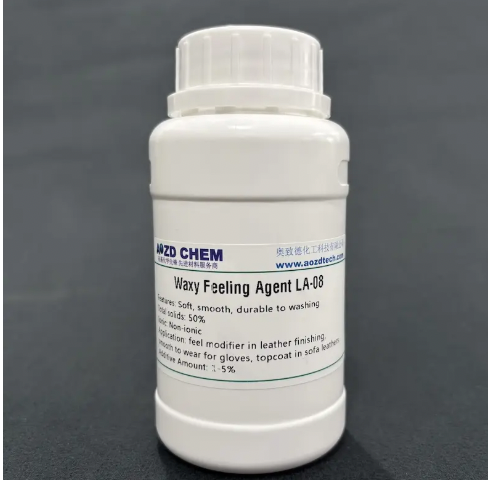

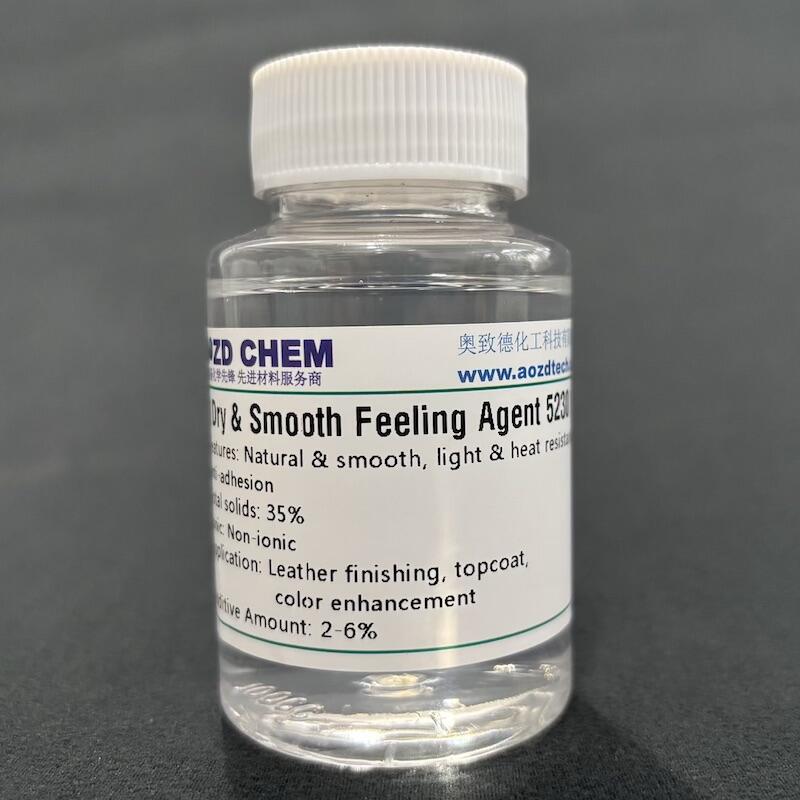

A High-End Leather Feel Modifier is a specialized formulation designed to enhance the tactile sensation, appearance, and overall premium feel of leather and synthetic materials. This product is widely used in industries that rely on sensory quality to define luxury value. Manufacturers apply a High-End Leather Feel Modifier to create consistent softness, smoothness, or elasticity depending on the design goals. By understanding the fundamental purpose of this modifier, businesses can make better decisions during product development and finishing stages.

Role of High-End Leather Feel Modifier in Luxury Manufacturing

In luxury goods manufacturing, a High-End Leather Feel Modifier helps control the final surface texture of leather without compromising durability. The modifier influences key properties such as suppleness, matte or glossy finish, resistance to abrasion, and natural touch. The product supports brands aiming to strengthen their craftsmanship identity and deliver materials that stand out in competitive markets.

Key Factors for Choosing a High-End Leather Feel Modifier

Importance of Material Compatibility

When selecting a High-End Leather Feel Modifier, material compatibility becomes a primary factor. Different leather types, coatings, and PU or PVC substrates require modifiers that interact smoothly with their chemical composition. A well-matched High-End Leather Feel Modifier ensures uniform results without issues such as uneven coating, stickiness, or reduced breathability. Testing compatibility ensures that the modifier enhances rather than hinders the material’s performance.

Performance Expectations for High-End Leather Feel Modifier

Manufacturers must also evaluate performance characteristics such as tactile quality, durability, heat resistance, and aging behavior. A reliable High-End Leather Feel Modifier should maintain softness and texture even under frequent use. Performance expectations include maintaining color stability, resisting wear, and offering a long-lasting premium feel that aligns with luxury standards.

Texture Enhancement with High-End Leather Feel Modifier

Achieving Softness and Smoothness

Softness and smoothness are among the most desirable traits in premium leather goods. A High-End Leather Feel Modifier helps enhance these characteristics by creating a refined, luxurious texture. With the right formulation, brands can achieve a velvety, delicate touch that appeals to high-end consumers. Consistent softness across large production batches is essential for maintaining brand reputation and product uniformity.

Creating Natural and Authentic Hand-Feel

The natural feel of leather is one of its most valuable attributes. A High-End Leather Feel Modifier enables manufacturers to refine this natural sensation while maintaining the authenticity of the material. Whether aiming for buttery softness or a firmer luxury texture, the modifier provides the flexibility needed to fine-tune sensory impact. This contributes to a more sophisticated end product.

Application Techniques for Better Results

Proper Mixing and Preparation

Effective use of a High-End Leather Feel Modifier begins with proper mixing. Correct dispersion ensures even distribution throughout the finishing formulation. Manufacturers should follow preparation guidelines to prevent separation or uneven texture. Adequate preparation enhances the modifier’s ability to deliver a premium tactile experience that meets luxury standards.

Optimizing Coating Process

The coating process greatly affects the final outcome. When applied efficiently, a High-End Leather Feel Modifier integrates seamlessly into the finishing layer, improving surface uniformity and resilience. Adjusting coating thickness, drying conditions, and curing parameters ensures the modifier performs optimally and provides the expected luxurious hand-feel.

Custom Requirements in Luxury Product Development

Tailoring Texture for Specific Market Segments

Different luxury markets require unique tactile characteristics. A High-End Leather Feel Modifier allows brands to customize textures to satisfy diverse consumer preferences, from ultra-soft luxury handbags to more structured automotive interiors. Tailoring texture enhances product differentiation and supports stronger market competitiveness.

Developing Signature Finishes

Many luxury brands aim to create signature finishes that reflect their design identity. A High-End Leather Feel Modifier plays a vital role in crafting these exclusive textures. By customizing modifiers, manufacturers can develop unique tactile impressions that distinguish their products in the high-end marketplace, helping the brand establish a recognizable sensory identity.

Performance Testing for High-End Leather Feel Modifier

Evaluating Durability

Before selecting a High-End Leather Feel Modifier, performance testing ensures the modifier meets durability expectations. Testing includes evaluating abrasion resistance, long-term flexibility, and the ability to withstand stress without losing tactile quality. A durable modifier contributes to the longevity and premium perception of the finished goods.

Assessing Environmental Resistance

Luxury goods often face environmental exposure such as humidity, UV light, body oils, and temperature changes. A High-End Leather Feel Modifier must maintain stability under varying conditions. Environmental resistance testing ensures the final product retains its softness, smoothness, and overall luxurious feel despite constant use.

Benefits of High-End Leather Feel Modifier in Manufacturing

Enhancing Product Perception

A High-End Leather Feel Modifier directly improves how consumers perceive leather goods. When a product feels luxurious to the touch, it reinforces brand image and enhances the overall value proposition. The modifier supports manufacturers in delivering products that meet buyer expectations for premium quality.

Increasing Market Competitiveness

Brands benefit from improved competitiveness when using a reliable High-End Leather Feel Modifier. Superior tactile performance sets products apart from competitors and strengthens the brand’s luxury positioning. Consistent refinement within the manufacturing process further improves customer trust and market presence.

Sustainability Considerations

Eco-Friendly Formulation Options

With growing environmental awareness, many manufacturers seek eco-friendly alternatives. Some High-End Leather Feel Modifier products now feature water-based or low-VOC formulations. These sustainable options reduce ecological impact while still providing exceptional tactile performance, allowing manufacturers to meet regulatory standards and consumer expectations.

Resource Efficiency in Production

Choosing the right High-End Leather Feel Modifier can also enhance resource efficiency. High-quality modifiers reduce the need for repeated applications, lower waste, and improve production consistency. Efficiency supports cost management while maintaining high luxury standards.

Conclusion

Selecting the best High-End Leather Feel Modifier is an essential step for brands aiming to deliver premium-quality leather goods. By focusing on compatibility, performance, texture customization, application techniques, and sustainability, manufacturers can ensure their products stand out in highly competitive luxury markets. A high-performing modifier elevates tactile sensation, strengthens market positioning, and enhances long-term consumer satisfaction.

FAQ

What is the purpose of using a High-End Leather Feel Modifier

A High-End Leather Feel Modifier enhances the tactile quality, smoothness, and premium feel of leather materials used in luxury goods manufacturing. It improves both the sensory appeal and performance of the final product.

How often should a High-End Leather Feel Modifier be tested

Regular testing is recommended whenever materials or production processes change. Testing ensures consistent tactile results and verifies that performance standards are maintained across all product batches.

What industries benefit the most from High-End Leather Feel Modifier

Industries such as luxury fashion, premium footwear, automotive upholstery, and high-end furniture benefit significantly from using a High-End Leather Feel Modifier due to their high emphasis on tactile quality.

Can a High-End Leather Feel Modifier improve product durability

A High-End Leather Feel Modifier can improve durability by enhancing surface resilience, maintaining softness, and resisting wear and environmental exposure.

Table of Contents

- Selecting High-End Leather Feel Modifier for Superior Luxury Finishes

- Understanding High-End Leather Feel Modifier

- Key Factors for Choosing a High-End Leather Feel Modifier

- Texture Enhancement with High-End Leather Feel Modifier

- Application Techniques for Better Results

- Custom Requirements in Luxury Product Development

- Performance Testing for High-End Leather Feel Modifier

- Benefits of High-End Leather Feel Modifier in Manufacturing

- Sustainability Considerations

- Conclusion

- FAQ