Თერმუსამართლებისა და თერმომართვა

Თერმუსამართლები მაღალი ტემპერატურის გარემოში

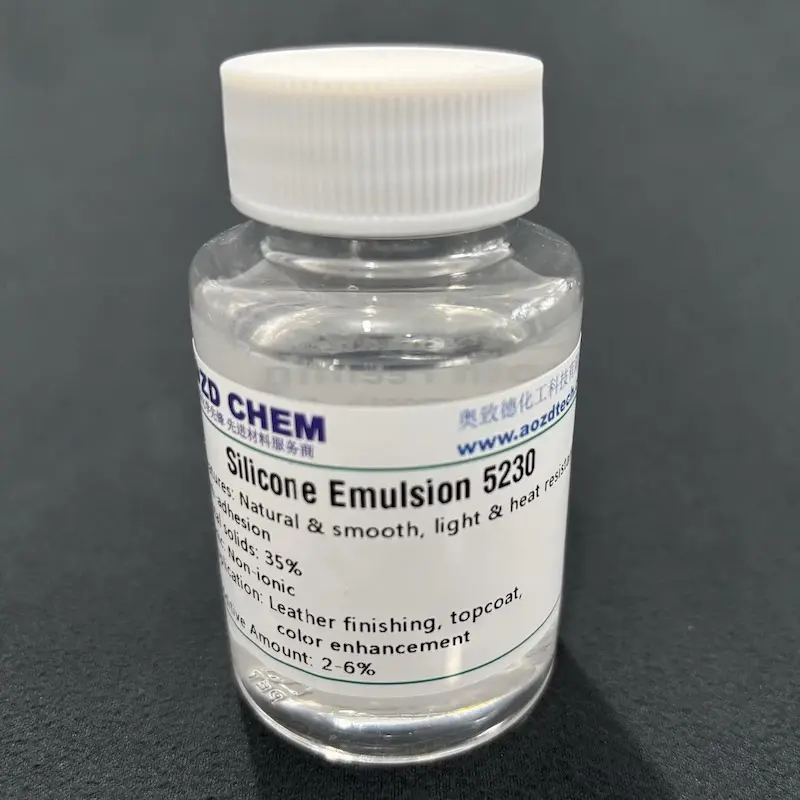

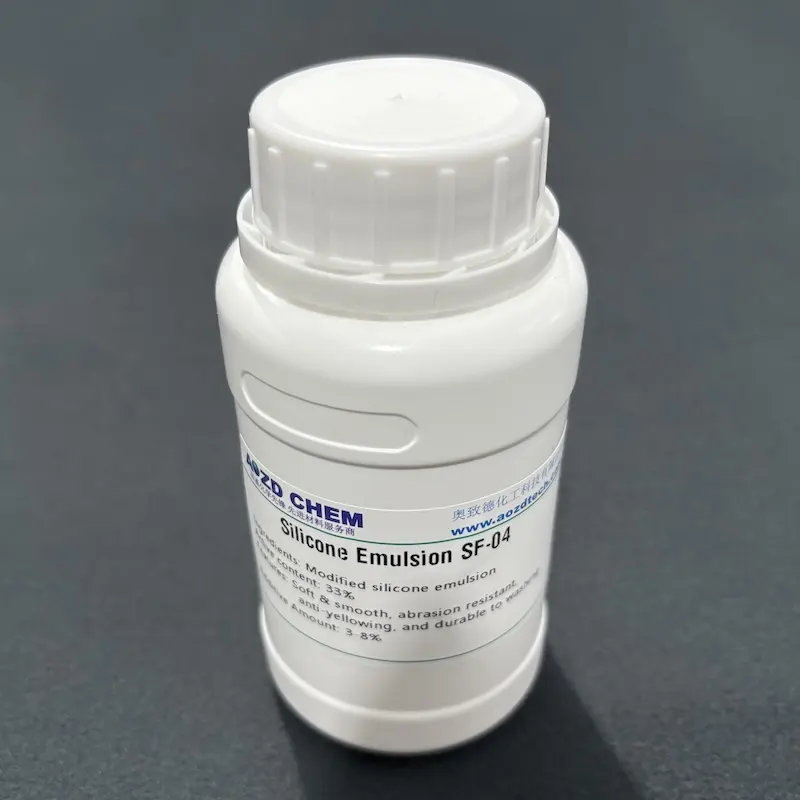

Სილიკონის ემულსიები ცნობილია, რომ ისინი უზრუნველყოფენ განსაკუთრებულ თერმულ სტაბილურობას, ანუ წინააღმდეგობას თბოგამძლეობას, რაც უზრუნველყოფს იმას, რომ ემულსიები არ დაშლიან ან მნიშვნელოვნად არ დაშლიან მაღალი ტემპერატურის პირობებში. სწორედ ეს თვისებები ხდის მათ განსაკუთრებულად მნიშვნელოვან რესურსად, განსაკუთრებით ავიაკოსმოსურ და ავტომობილების სამრეწველო შემთხვევებში, სადაც მასალები ხშირად გამოიწვევა 200°C-ზე მაღალ ტემპერატურას, ხოლო კვლევებმა აჩვენა, რომ სილიკონები შეძლებენ შეინარჩუნონ თავიანთი სტრუქტურა და თვისებები ასეთ მაღალ ტემპერატურაზე, რაც უზრუნველყოფს ამ მასალების საიმედოობას და უსაფრთხოებას. ასეთ შემთხვევებში სილიკონის ემულსიები უზრუნველყოფს საიმედო, მდგრად დამუშავებას და ნაწილების სიცოცხლის ხანგრძლივობას სიცხის ექსტრემალურ პირობებში.

Სილიკონის ემულსიების სითბოს გადაცემის მექანიზმის გაგება მნიშვნელოვანია უკეთესი გაგრილების მოწყობილობების შესაქმნელად. ისინი იყენებენ სილიკონის ემულსიების სპეციალურ თვისებებს სითბოს გადაცემის ჩასახშობად და შესაბამისად, უფრო მეტად გააუმჯობინონ უსაფრთხოება სწრაფი და მაღალი ტემპერატურის მქონე პირობებში. სილიკონის ემულსიების გამოყენებით, ინჟინრებს შეუძლიათ შექმნან ისეთი პროდუქტები, რომლებიც უფრო იოლად აკონტროლებენ სითბოს მოცილებას პროდუქტიდან, რათა უზრუნველყონ გრძელვადიანი სიცოცხლისუნარიანობა მიუხედავად ექსტრემალური პირობებისა. ეს განსაკუთრებით მნიშვნელოვანია აეროკოსმოსური და ავტომობილების შემდეგი თაობის განვითარებისთვის, სადაც სითბური რეჟიმის უპირატესობა მთავარ შესრულების ფაქტორს წარმოადგენს.

Კომპონენტების გამოწვევის პრევენცია

Ერთ-ერთი ყველაზე მნიშვნელოვანი რამ, რაც უნდა გააკეთოთ იმისთვის, რომ თქვენი მოწყობილობა გრძელ ხანს იმუშაოს, გაგრილდეს და დაცული იყოს (გადახურებისგან): *მოწყობილობის მოვლა: ტემპერატურის გაგრილების შენარჩუნება უზრუნველყოფს თქვენი კომპიუტერების და სხვა ელექტრონული პროდუქტების ეფექტურობას, ამიტომ ჩვენ გვაქვს ამის თავიდან ასაცილებლად სილიკონის ემულსიების გამოყენების ამონახსნი. ეს ემულსიები მოქმედებს როგორც საშუალება სითბოს ეფექტური გასაგრილებლად და მნიშვნელოვნად ამცირებს გადახურების შემთხვევებს სითბოს უკეთესი გამოსხივების შედეგად. სილიკონის ემულსიები გამოიყენება როგორც საფარი ან სპრეი ელექტრონული კომპონენტების ზედაპირის თვისებების გასაუმჯობესებლად, რათა უკეთესად გავრცელდეს ჭარბი სითბო. ეს არა მხოლოდ აცავს ამ კომპონენტებს ზიანისგან, არამედ ამაღლებს მათ სამუშაო ეფექტურობას.

Სილიკონის ემულსიების თბოგამტარობის უნარი შეიძლება გაიზარდოს რამდენიმე მეთოდის გამოყენებით, მაგალითად, სპრეის ან საფარის დამუშავებით. ეს მეთოდები ადგილობრივ დამუშავებას უზრუნველყოფს, რაც ეფექტურ თერმულ მართვას უზრუნველყოფს მიუწვდომელ ადგილებშიც კი. ასევე, მონაცემები აჩვენებს, რომ მოწყობილობებს, რომლებიც იყენებენ სილიკონის ემულსიებზე დაფუძნებულ თერმულ მართვას, ნაკლები ხარვეზის მაჩვენებელი აქვთ ტრადიციული მეთოდების გამოყენების შემთხვევაში. მაგალითად, ელექტრონიკას, რომელიც იყენებს სილიკონზე დაფუძნებულ თერმულ ამონახსნებს, 20%-ით ნაკლები ხარვეზის მაჩვენებელი აქვს და სილიკონის ემულსიები საკმაოდ ეფექტურია ელექტრონიკის გადახურებისა და შემდგომი გაუმართაობისგან დასაცავად.

Სითხის და გარემოს დაცულობა

Ელექტრონიკის დაცული გამოსაღები ტელი

Სილიკონის ემულსია მნიშვნელოვან დამცველ საშუალებას წარმოადგენს ელექტრონიკისთვის, სინამდვილეში სათბო პირობებშიც. ასევე გამოვლინდა, რომ სილიკონის ემულსიით დაფარულ ელექტრონულ მოწყობილობებზე სითბოს შთანთქმის მაჩვენებელი მნიშვნელოვნად შემცირდა, რის შედეგადაც ელექტრონული მოწყობილობების სასარგებლო ვადა მკვეთრად გაიზარდა. სითბოს შემცირებული შთანთქმა განსაკუთრებით მნიშვნელოვანია ღია ადგილების ელექტრონიკის შემთხვევაში, სადაც სითბოს მიმართ მდგრადობა პროდუქის სიცოცხლისთვის გადამწყვეტია. მაგალითად, იმის გამო, რომ სილიკონი წყალგამძლე სივრცეს ქმნის, ეს უზრუნველყოფს მუდმივ შესრულებას ცვალებადი ამინდის პირობებში და იცავს ღირებულ ელექტრონიკულ მოწყობილობებს სითბოს ზიანისგან.

Დაცვა კოროზიისა და გამოქვევის წინ

Სილიკონის ემულსიების როლზე კვლევა მნიშვნელოვანია მეტალის ნაწილებისთვის, რომლებიც გამოიყენება მრეწველობის პროცესში და რომლებიც უზრუნველყოფს უამრავ უპირატესობას. სილიკონის ემულსიები ქმნიან დამცავ საფარს, რომელიც აიოლებს აგრესიულ გარემოს, რომელიც შეიძლება გამოიწვიოს კოროზია. სილიკონი წარმოადგენს სტაბილურ სტრუქტურას, რის გამოც იგი მდგრადია აქტიური ქიმიკატების მიმართ, ხოლო სილიკონის ემულსიები უფრო ნაკლებად იკოროზიებს დროთა განმავლობაში. არსებობს მრავალი მაგალითი მრეწველობის სფეროებში, როგორიცაა მშენებლობა, ავიაკოსმოსი და სხვ., რომლებიც ადასტურებს სილიკონის ემულსიების გამოყენების სარგებელს მეტალის ნაწილების სიცოცხლის ხანგრძლივობის გაზრდის მიზნით ტრადიციული დამცავი საფარების შედარებით. ეს გაზრდილი მდგრადობა ხელს უწყობს გარემოს დაცვას ამ სფეროებში და ამით სილიკონის ემულსიები ხდება მნიშვნელოვანი მრეწველობისთვის ეკოლოგიური ტექნოლოგიების განვითარებაში.

Adhesion-ის და ზედაპირ მუშაობის გაუმჯობესება

Durable Connections-ის დაკავების გაუმჯობესება

Სილიკონის ემულსიები მნიშვნელოვან როლს ასრულებენ ადგენზიის გაუმჯობესებაში და განსხვავებული მასალების შეერთებაში ელექტრონული აპლიკაციებისთვის გრძელვადიანი კავშირების უზრუნველყოფაში. რადგან ის შეუძლია ზედაპირული ენერგიის გაზრდა, სილიკონის ემულსია უზრუნველყოფს კარგ თანდაყოლას განსხვავებულ მასალებს შორის, რაც აუცილებელია ელექტრონული კომპონენტების საიმედოობისა და ეფექტურობისთვის. ეს განსაკუთრებით მნიშვნელოვანია ინდუსტრიებში, როგორიცაა ავტომობილების ელექტრონიკა და კონფორმული საფარი, სადაც კავშირის მთლიანობა კრიტიკულ მნიშვნელობას ასაკებს. წინა ხელოვნების პატენტებში გამოქვეყნებულია იმის შესახებ ინფორმაცია, რომ სილიკონის ემულსიები იყენებენ ზედაპირის დამუშავებაში საფარის ფილმების წარმოქმნისთვის, ხოლო ამ ავტორების კვლევებმა აჩვენა, რომ სილიკონის ემულსიები უფრო მაგრად და გრძელი ხანით შეუძლიათ ადგეზიური ბმების წარმოქმნა და ელექტრონული პროდუქტების გამართულების შემცირება, თუ იქნებიან გამოყენებული. მაგალითად, ანალიტიკური შეფასებები აღნიშნავს, რომ სილიკონის ემულსიები შეუძლიათ 30%-ით მეტი ხანგრძლივობა დაუმატონ კავშირებს, რაც სხვაგვარად ნიშნავს, რომ ის კარგად მუშაობს ყველაფერზე მდგრადი კავშირების წარმოსაქმნელად.

Ზედაპირის დამთავრების ოპტიმიზაცია ზუსტი კომპონენტებისთვის

Მნიშვნელოვანია როგორც მედიცინისთვის, ასევე ზუსტი ინჟინერიისთვის, რომ მიღებულ იქნას უწყვეტი ზედაპირები და სილიკონის ემულსიები ამ მიზნის მისაღწევად გადამწყვეტ ელემენტს წარმოადგენენ. სილიკონის ემულსიები ავსებს ზედაპირის მცირე ხარვეზებს, რათა მნიშვნელოვნად გაუმჯობინოს კრიტიკული ნაწილების გარეგნობა და შესრულების ხარისხი. ამ ემულსიების მიერ მიწოდებული უმჯობესი ზედაპირის დამუშავების ხარისხი განსაკუთრებით სასარგებლოა ავიაკოსმოსურ და ავტომობილების ელექტრონიკულ ინდუსტრიაში. პრაქტიკაში დაფიქსირდა, რომ არსებობს მკვეთრი განსხვავება სილიკონის ემულსიით დამუშავების მქონე და დამუშავების მომენტის შემდეგ პროდუქის ზედაპირის დამუშავებას შორის, სილიკონის ემულსიით დამუშავების შემდეგ კი პროდუქს აქვს უმეტესი ცვეთის მედეგობა. ავტომობილების სექტორში, სადაც მაღალი შესრულების სტანდარტებია, სილიკონის ემულსიები გამოიყენება დასამთავრებელი პროცესის ნაწილად იმ კომპონენტების დასამუშავებლად, რომლებიც უნდა აკმაყოფილებდნენ ძალიან ზუსტ სპეციფიკაციებს. ზედაპირის დამუშავების ხარისხის მაქსიმიზების ეს შესაძლებლობა ამ strengthening-ს სილიკონის ემულსიების სტატუსს მაღალი შესრულების მქონე, ზუსტად ინჟინერირებული ნაწილების შემუშავებაში.

Საშუალება გვაძლევს ლექსი და მოწყვეტილ ელექტრონიკის გამოყენებას

Გაღებადი ცირკუიტები და გამალენებელი კომპონენტები

Სილიკონის შემცველი ემულსიები ბოლო რამდენიმე წლის განმავლობაში სილიკონის შემცველი ემულსიები ახალ სტანდარტებს ამყარებენ მოქნილი ელექტრონიკის სტრუქტურის სფეროში, რაც საშუალებას აძლევს წრეს ყველა მიმართულებით გაწელვასა და დაღუნვას, რათა მიიღოს სხვადასხვა კონფიგურაცია. სხვა მოქნილ მასალებთან ერთად მათი გამოყენება რევოლუციურია ტარებადი ტექნოლოგიების სფეროში, რადგან ის იძლევა შესაძლებლობებს, რომლებიც ადრე შეუძლებელად ითვლებოდა. პოლიმერებთან და ტექსტილთან მისი თავსებადობის გამო, შესაძლებელი ხდება ელექტრონიკის შექმნა, რომელიც შეიძლება ტარდეს ან პირდაპირ ჩაიკიდოს ტანსაცმელში. მოქნილი ელექტრონიკის ბაზარი სწრაფად ვითარდება, როგორც აჩვენებს ინდუსტრიის ანგარიშები. მოლოდინია, რომ მოთხოვნა გაიზრდება, რადგან მომხმარებლების მიემატება ისეთი ელექტრონიკის მიმართ მოთხოვნა, რომელიც მსუბუქი, მოქნილი და მაღალი სიმძლავრისაა. ეს პროგრესი ხდის იმდენად მოქნილ და ფუნქციონალურ ტექნოლოგიას, რომ მისი მომავალი არა მხოლოდ ტარებადი იქნება, არამედ თითქმის უჩინარი.

Დამალებადობა დინამიურ აპლიკაციებში

Იმ გამოყენების სფეროში, სადაც მოქნილობა ძალიან მნიშვნელოვან პარამეტრს წარმოადგენს, სილიკონი თავისი ბუნებრივი ელასტიურობისა და ჭიმვის მდგრადობის წყალობით საუკეთესო მასალად იქცევა. სილიკონის ემულსიებით დამუშავებული ელექტრონული კომპონენტები დინამიურ და ცვალებად პირობებში განსაკუთრებულ მდგრადობას ამჟღავნებენ. გაფართოებულმა ტესტირებამ ყოველთვის დაადასტურა, რომ სილიკონის ნაწილები საკმაოდ მდგრადია დაძაბულობის გამო დაზიანების მიმართ, რაც დინამიური გამოყენების შემთხვევაში სერიოზულ პრობლემას წარმოადგენს. ჩაცმადი ტექნოლოგიები, როგორიცაა ფიტნეს-ტრეკერები და სმარტ-საათები, ამ თვისების გამოყენებას უკვე მოახდინეს, რაც ასევე ადასტურებს, თუ როგორ აღმოფხვრის სილიკონი მდგრადობის პრობლემებს. ამ წარმატებულმა გამოყენებებმა კიდევ უფრო გაამტკიცეს სილიკონის პოტენციალი, როგორც იმ პროდუქების სიცოცხლის ხანგრძლივობის გასაგრძელებლად და მათი საიმედოობის შესანარჩუნებლად, რომლებიც აქტიურ და მძიმე პირობებში გამოყენებაზეა განკუთვნილი.

Დიელექტრიკური თვისებები და ელექტროსაფეხურის უსაფრთხოება

Მდგინარე იზოლაციის გარანტირება

Სილიკონის ემულსიები გადამწყვეტ როლს ასრულებს სტაბილური ელექტრული იზოლაციის უზრუნველყოფაში და გამტარობის რისკის შემცირებაში მგრძნობიარე გარემოში. სილიკონის ემულსიების დიელექტრიკული თავდახურვა ქმნის არაგამტარობის აუცილებელ ფენას დენის წინააღმდეგ, რაც იცავს როგორც მოწყობილობებს, ასევე ოპერატორებს. მაგალითად, დიელექტრიკული გატეხილობის ძაბვა არის მნიშვნელოვანი პარამეტრი ამ ემულსიების შესაბამისობის შესაფასებლად ელექტრულ გამოყენებებში. ზოგადად, სილიკონის ემულსიებს აქვთ შედარებით მაღალი დიელექტრიკული თავდახურვა, რაც ამცირებს ელექტრული გამშვებების წარმოქმნის ალბათობას.

Სილიკონის ემულსიების საიმედოობის დასადასტურებლად მნიშვნელოვანი გამოყენებისთვის, რამდენიმე სტანდარტი და ავტორიტეტული გამოცემა მხარს უჭერს მათ იზოლაციურ შესრულებას. ეს სპეციფიკაციები უზრუნველყოფს იმას, რომ სილიკონის ემულსიები უზრუნველყოფს საჭირო უსაფრთხოების მახასიათებლებს, რომლებიც შეესაბამება სამრეწველო სტანდარტის ელექტრულ იზოლაციას. ეს ნიშნავს, რომ ელექტრონიკა, განსაკუთრებით მნიშვნელოვან სფეროებში, როგორიცაა ჯანდაცვა და ავიაკოსმოსი, დაცულია нежელადობითი ელექტრული ჩარევისგან, რაც აუმჯობესებს როგორც შესრულებას, ასევე უსაფრთხოებას.

Რისკის შემცირება კოროტნების შემთხვევაში

Თავის მხრივ, სილიკონის ემულსიები შეიძლება გამოვლინდეს მოკლე ჩაქცევის რისკის მნიშვნელოვან შემცირებაში, რადგან გამტარ მასალებს შორის წარმოიქმნება მყარი იზოლაცია. ელექტრული ნაწილების პირდაპირი კონტაქტის თავიდან აცილებით, სილიკონის ემულსიები უზრუნველყოფს სისტემების საიმედოობასა და უსაფრთხოებას, ეფექტურად ასრულებს საპრევენციო ზომას წრედის გამართულების წინააღმდეგ. ამ ემულსიების სტაბილურობა რეალურ ელექტრო სისტემებში ადასტურებს მათ უმიზეზო მუშაობის მინიმალური პირობების შესაძლებლობას, ხოლო ამ მასალების მიერ მიწოდებული იზოლაცია საშუალებას აძლევს სისტემებს მუდმივი ექსპლუატაციის შენარჩუნებას.

Სილიკონის იზოლაციის შესახებ ტესტები და ისტორიული მონაცემები აჩვენებს მის უნარს, შეამციროს მოწყობილობების გამართულები მოკლე ჩართვების გამო. რამდენიმე კვლევა აღნიშნავს ბუშინგის გამართულების შემცირებას სისტემებში, სადაც გამოიყენება სილიკონის იზოლატორები, რაც ადასტურებს მათ მნიშვნელობას სისტემის საიმედოობის უზრუნველყოფაში. ამ უნარმა, რისკის ასეთ ზომაში შემცირება, შეიძლება რამდენიმე წლით გააგრძელოს თქვენი მოწყობილობების სამსახურის ვადა და გაზარდოს ოპერაციული უსაფრთხოება, რაც სილიკონის ემულსიებს უსაფრთხო და ხარვეზების გარეშე ელექტრო სისტემების აუცილებელ ინგრედიენტად აქცევს.

Ხელიკრული

Რა არის სილიკონის ემულსიების ძირითადი გამოყენებები მაღალი ტემპერატურის გარემოებში?

Სილიკონის ემულსიები ძირითადად გამოიყენება ჰაეროსფერი და ავტომობილურ ინდუსტრიებში მათი თერმალური стабილურობის გამო, რაც ადევნებს მათ მოქმედებას გარემოებში, სადაც ტემპერატურები აღემატებენ 200°C.

Როგორ აvertებენ სილიკონის ემულსიები კომპონენტების გათბობას ელექტრონიკაში?

Მათი გამოყენების შედეგად, როგორც ჩაფლებები ან სპრეიები, ისინი გაუმჯობებენ გრძნობის გამოტანას, ელექტრონული კომპონენტების ზღვარის თვისებების გაუმჯობებით, რათა შესახელოს გამოწვევა და გაუზრავონ მოწყობილობის გაცხვრება.

Რა საფრთხე აძლევენ სილიკონის ემულსიები ტენისა და ტენის წყლის წინ?

Ისინი ფორმირებენ წყლისგან გართიელ ბარიერს ელექტრონიკაზე, საკმარისად დაბალ წყლის შესაჭერი სიჩქარეებით და დაცვით ტენისგან გამოწვევისგან.

Როგორ გაუმჯობებენ სილიკონის ემულსიები ჩართვასა და ზღვარის დასრულებას?

Ისინი ზრდიან ზღვარის ენერგიას სამსახურების უკეთ ჩართვისთვის და შევსებენ ნებისმიერ ნებადი ნაწილებს, რათა გაუმჯობებინ ზღვარის დასრულებას ავტომობილურ და ჰაერონავტიკურ ელექტრონიკაში.

Არის თუ არა სილიკონის ემულსიები სასარგებლო და მოწევადი ელექტრონიკისთვის?

Კი, ისინი შესაძლებლობას ძლევენ გამრუდებადი ცირკუიტებისა და გამოყენებისთვის, რათა ელექტრონიკა შესაბამისი გახდეს სასარგებლო მასალებთან, გაუზრავონ ელექტრონიკის მოწევადობა და ადაპტაცია.

Რა მოქმედება აქვს სილიკონის ემულსიებს ელექტროსაფრთხეზე?

Ისინი გაუზარდებენ მხოლოდ მაღალ დიელექტრული სიკარგადობით, რაც შემცირებს ელექტროწინააღმდეგობის და მოკლე წირების რისკებს სენსიტიურ გარემოში, დაცვილიყოფა ჩარჩოებსა და მომხმარებლებს.

Შინაარსის ცხრილი

- Თერმუსამართლებისა და თერმომართვა

- Სითხის და გარემოს დაცულობა

- Adhesion-ის და ზედაპირ მუშაობის გაუმჯობესება

- Საშუალება გვაძლევს ლექსი და მოწყვეტილ ელექტრონიკის გამოყენებას

- Დიელექტრიკური თვისებები და ელექტროსაფეხურის უსაფრთხოება

-

Ხელიკრული

- Რა არის სილიკონის ემულსიების ძირითადი გამოყენებები მაღალი ტემპერატურის გარემოებში?

- Როგორ აvertებენ სილიკონის ემულსიები კომპონენტების გათბობას ელექტრონიკაში?

- Რა საფრთხე აძლევენ სილიკონის ემულსიები ტენისა და ტენის წყლის წინ?

- Როგორ გაუმჯობებენ სილიკონის ემულსიები ჩართვასა და ზღვარის დასრულებას?

- Არის თუ არა სილიკონის ემულსიები სასარგებლო და მოწევადი ელექტრონიკისთვის?

- Რა მოქმედება აქვს სილიკონის ემულსიებს ელექტროსაფრთხეზე?