leather hand feel

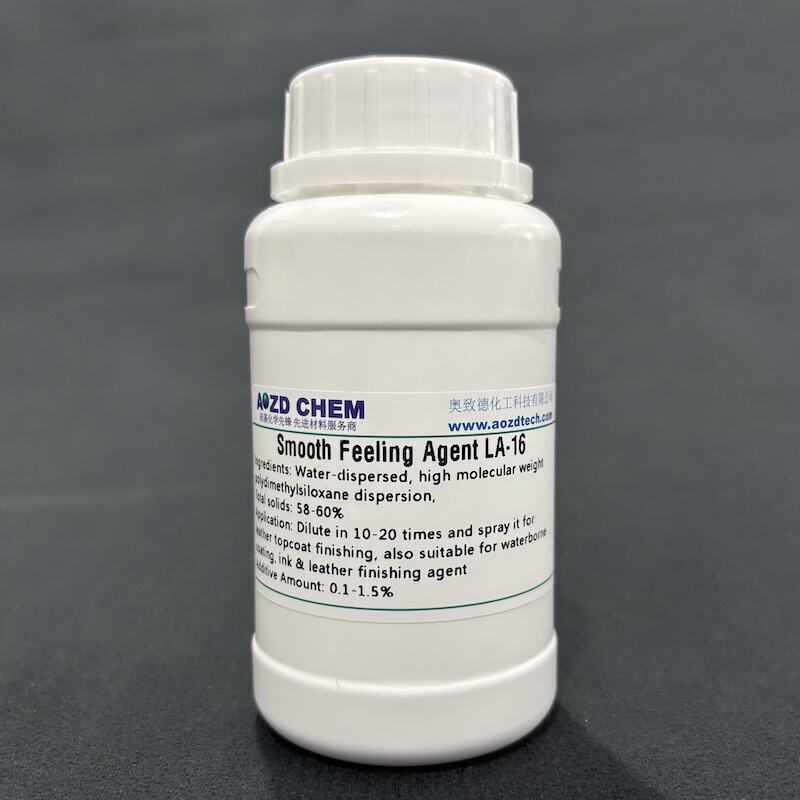

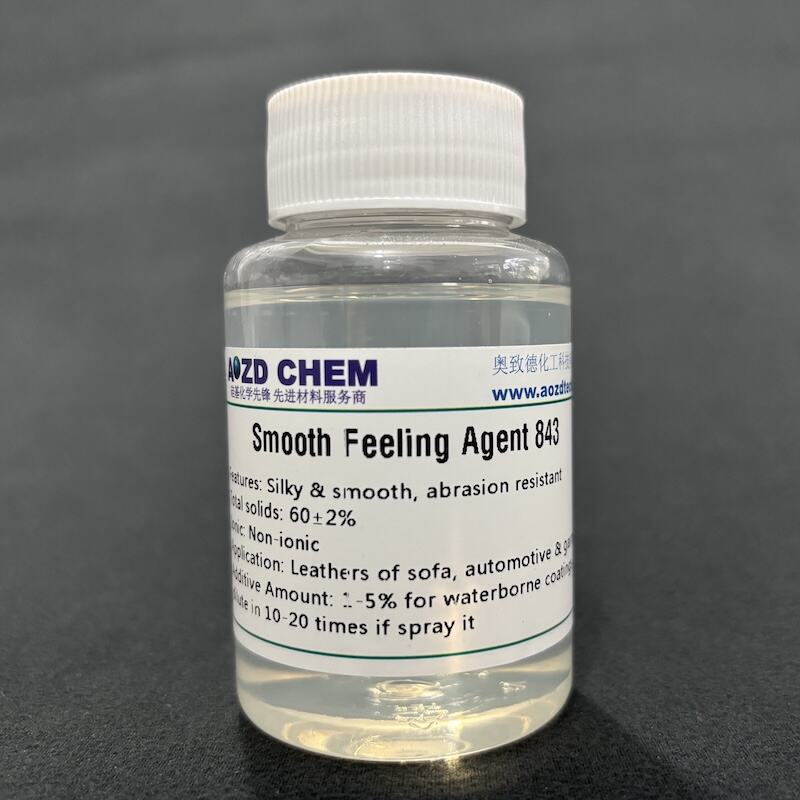

Leather hand feel technology represents a revolutionary advancement in material surface treatment, offering a sophisticated solution for creating premium tactile experiences across various products. This innovative process combines specialized coating techniques with advanced polymer science to replicate the luxurious sensation of genuine leather. The technology encompasses multiple layers of treatment, including a base coating that provides durability, a middle layer that creates the characteristic leather grain texture, and a top coating that delivers the final tactile sensation. The process utilizes environmentally conscious materials while maintaining high-performance standards, ensuring both sustainability and quality. The technology can be applied to various substrates, including plastics, synthetics, and composite materials, making it versatile for multiple industries. The resulting surface exhibits remarkable durability, resistance to wear, and maintains its leather-like properties throughout extended use. This technology finds applications in automotive interiors, consumer electronics, fashion accessories, and furniture manufacturing, where it provides an economical alternative to genuine leather while maintaining premium feel and appearance.