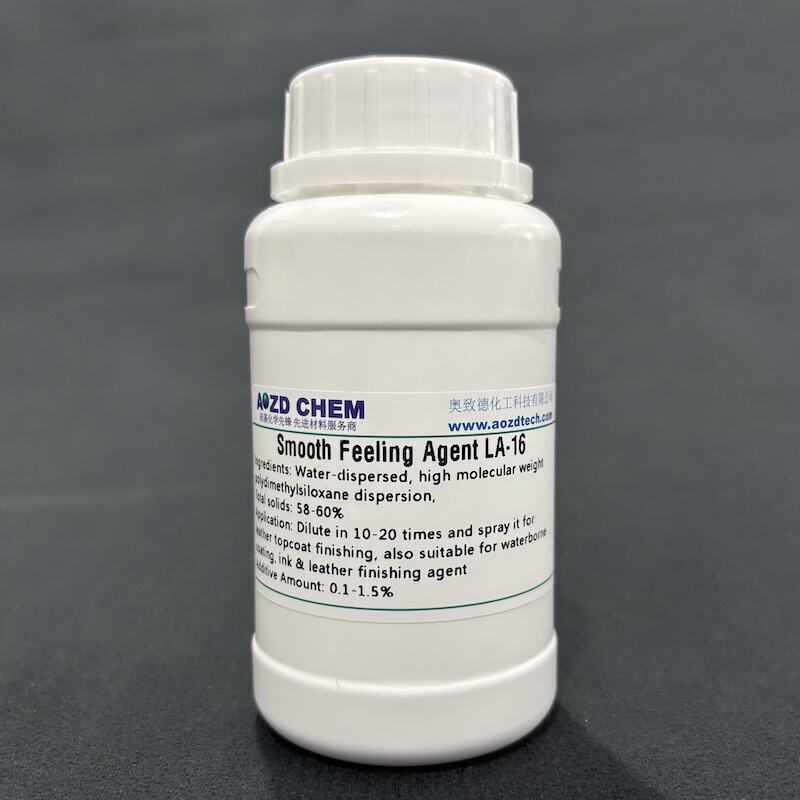

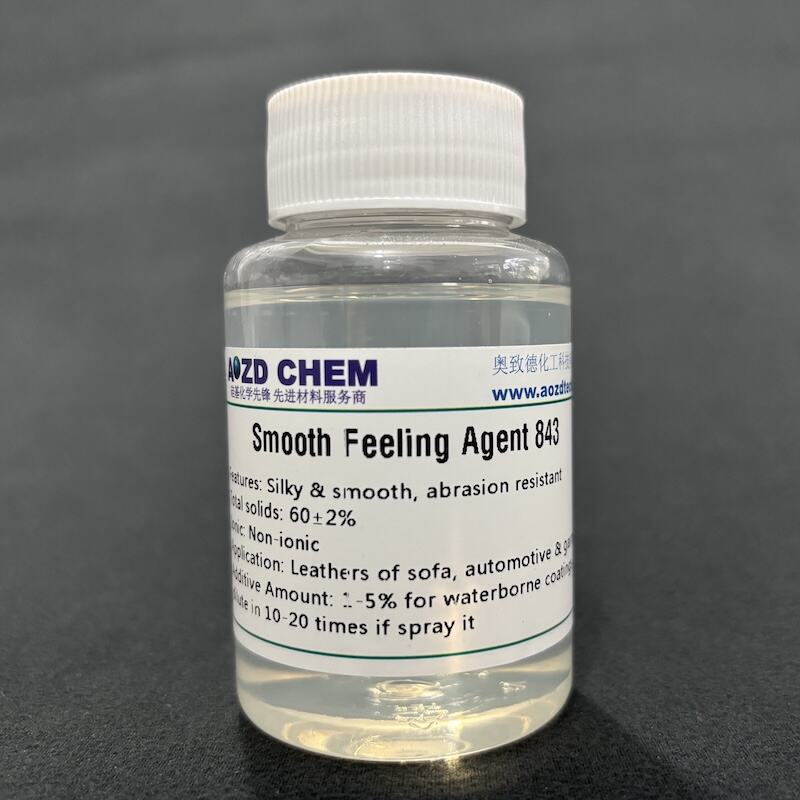

soft hand feel additives

Soft hand feel additives are specialized chemical compounds designed to enhance the tactile properties of various materials, particularly textiles and synthetic fabrics. These innovative additives work by modifying the surface characteristics of fibers, creating a luxuriously smooth and comfortable touch sensation that mimics natural materials. The technology behind these additives involves advanced polymer science, where microscopic particles are engineered to create a uniform coating that reduces surface friction and increases material flexibility. These additives are particularly valuable in the textile industry, where they transform synthetic fabrics from rigid and artificial-feeling materials into soft, pleasant-to-touch surfaces that rival natural fibers. They function by forming a microscopic layer that modifies the coefficient of friction between the fabric and skin, while simultaneously maintaining the material's essential properties such as durability and wash resistance. The applications span across various sectors, including apparel manufacturing, home textiles, automotive fabrics, and technical textiles. What makes these additives particularly remarkable is their ability to maintain their effectiveness through multiple washing cycles, ensuring long-lasting performance and consumer satisfaction.