best expancel microspheres

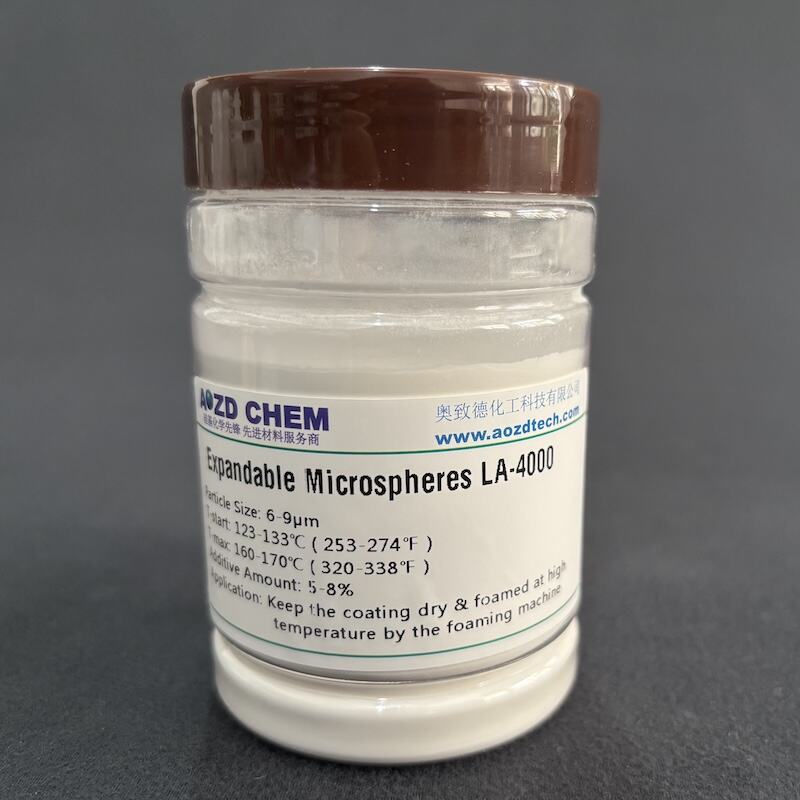

Expancel microspheres represent a breakthrough in advanced polymer technology, offering exceptional versatility and performance across various applications. These sophisticated thermoplastic spheres contain a hydrocarbon gas encapsulated within a specialized polymer shell, enabling them to expand dramatically when exposed to heat. The best expancel microspheres demonstrate remarkable expansion capabilities, increasing up to 50 times their original size while maintaining structural integrity. Their unique composition allows for precise control over density reduction, thermal insulation, and material enhancement. These microspheres are available in different grades, each optimized for specific temperature ranges and expansion ratios, making them suitable for diverse manufacturing processes. When incorporated into various materials, they significantly improve product characteristics such as weight reduction, thermal insulation, and acoustic properties. The technology behind these microspheres ensures consistent performance across applications ranging from automotive components to construction materials, packaging solutions, and specialty coatings. Their controlled expansion process and uniform particle size distribution contribute to reliable and reproducible results in manufacturing processes, while their closed-cell structure provides excellent stability and durability in final products.