expancel microspheres for leather

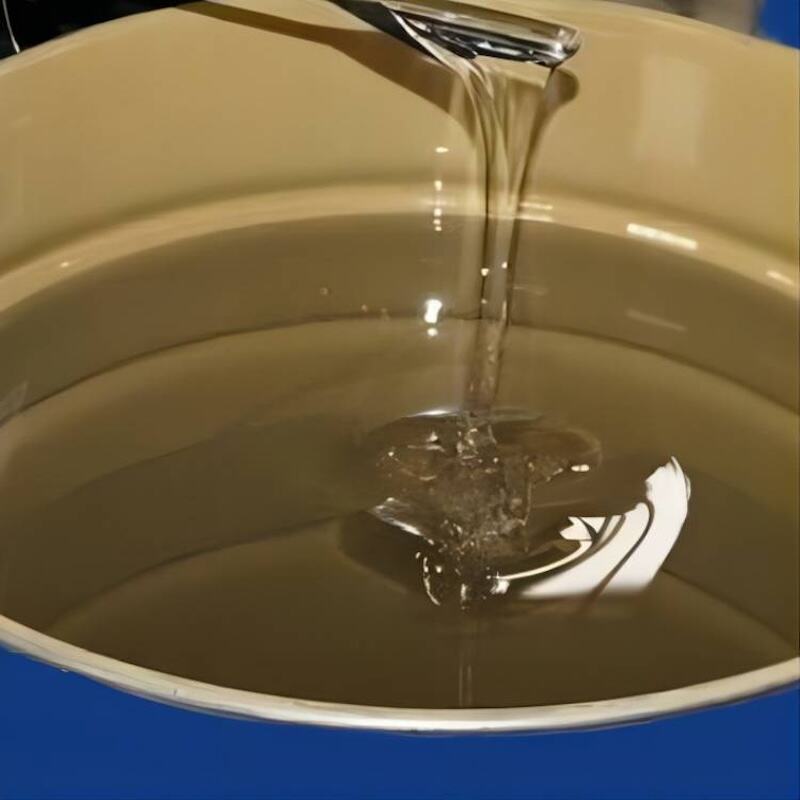

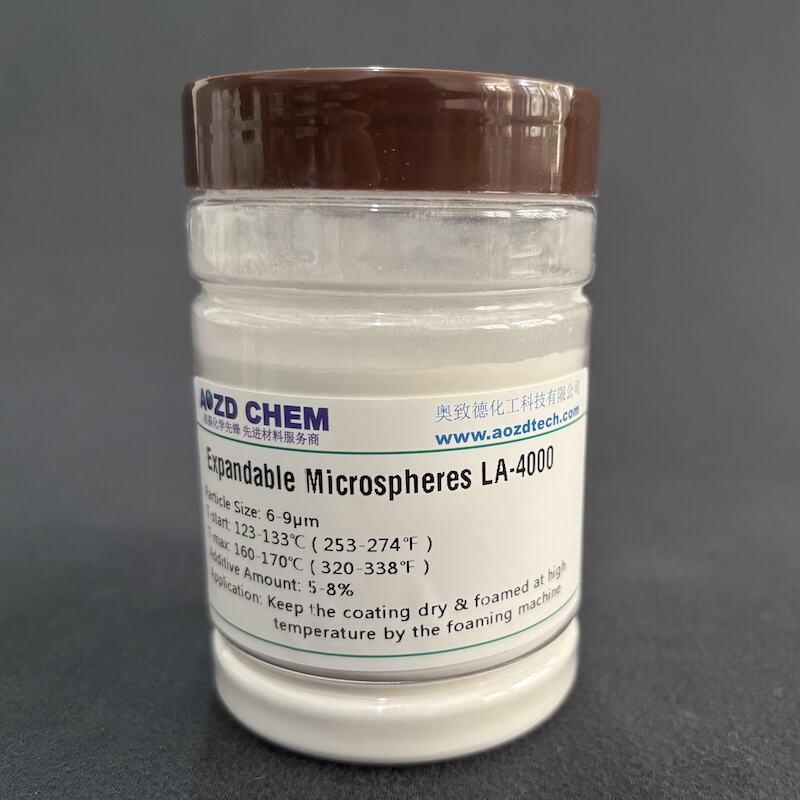

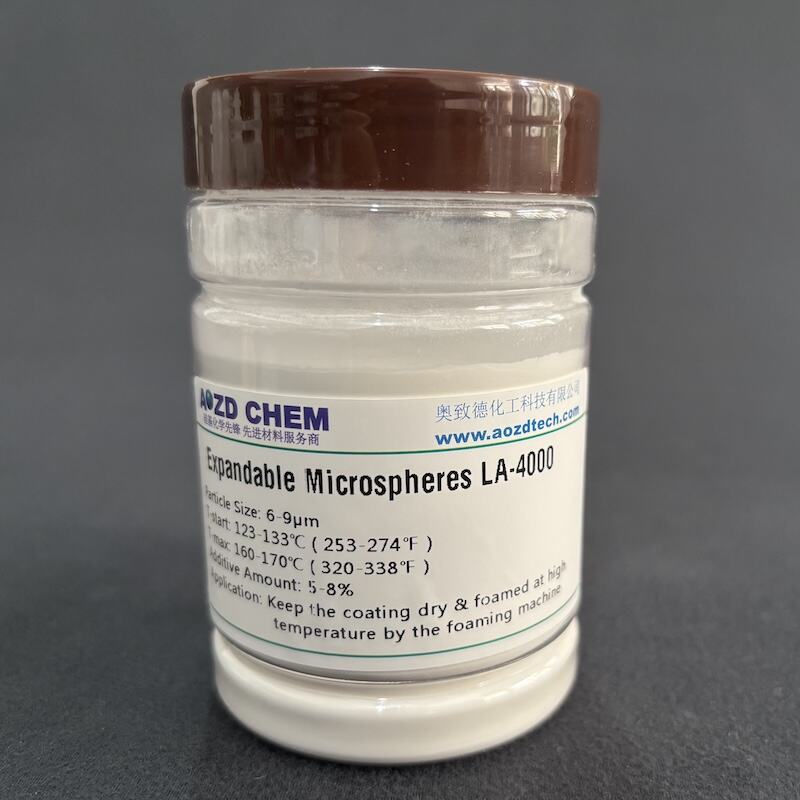

Expancel microspheres represent a groundbreaking innovation in leather manufacturing, offering unique properties that enhance both the production process and final product quality. These thermoplastic microspheres contain a hydrocarbon gas core encapsulated within a polymer shell, which expands when exposed to heat. In leather applications, these microspheres typically range from 10 to 40 microns in size before expansion and can increase up to 40 times their original volume when activated. The technology enables manufacturers to achieve consistent thickness and improved thermal insulation properties in leather products. When incorporated into leather processing, these microspheres create a uniform cellular structure that contributes to weight reduction while maintaining the material's durability and flexibility. The microspheres can be integrated at various stages of leather processing, including during coating or finishing operations, providing manufacturers with versatile application options. Their controlled expansion characteristics allow for precise control over the final leather properties, making them particularly valuable in producing high-quality leather goods that require specific performance attributes. The technology has proven especially beneficial in automotive leather, furniture upholstery, and premium leather goods manufacturing, where consistent quality and enhanced performance characteristics are essential.