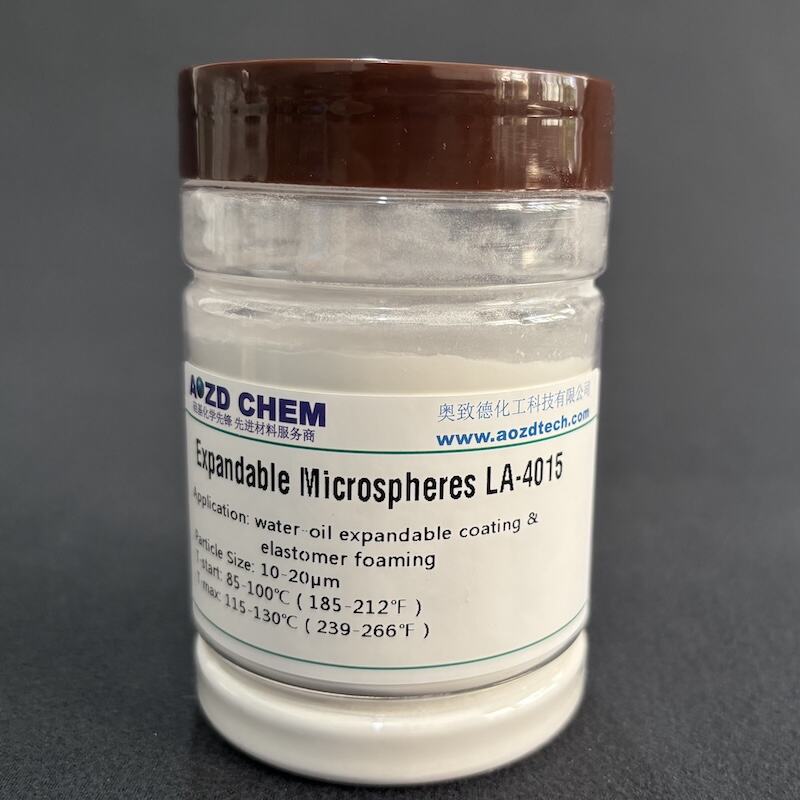

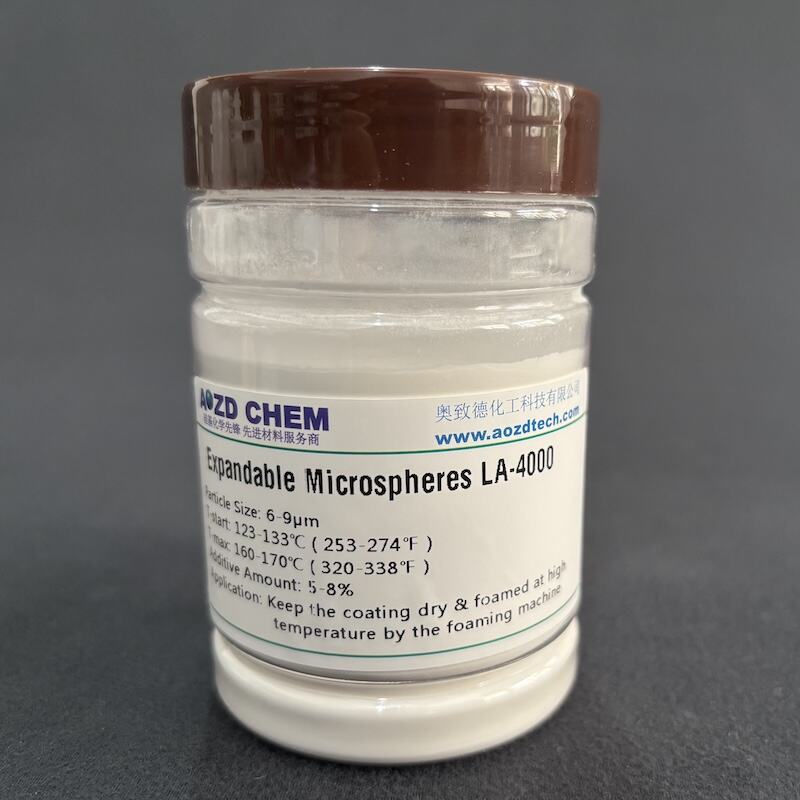

the expancel microspheres

Expancel microspheres represent a groundbreaking advancement in polymer technology, consisting of tiny thermoplastic spheres encapsulating hydrocarbon gas. When exposed to heat, these microspheres undergo a remarkable expansion process, increasing in size by up to 40 times their original volume while maintaining extremely low density. These expandable microspheres are engineered with a thermoplastic shell that softens as temperature rises, allowing the encapsulated hydrocarbon to expand the sphere without breaking it. Available in various grades and sizes, Expancel microspheres can be customized for specific temperature ranges and applications. They serve as exceptional lightweight fillers in numerous industries, including automotive, construction, and packaging. The microspheres contribute to significant weight reduction in end products while maintaining or enhancing mechanical properties. In coating applications, they create unique textures and improve insulation properties. Their controlled expansion characteristics make them invaluable in sealants, where they can fill gaps and create reliable seals. The technology behind Expancel microspheres allows for precise control over density reduction, making them ideal for applications requiring specific weight-to-volume ratios. Their closed-cell structure ensures consistent performance and prevents moisture absorption, contributing to the longevity of the final products.