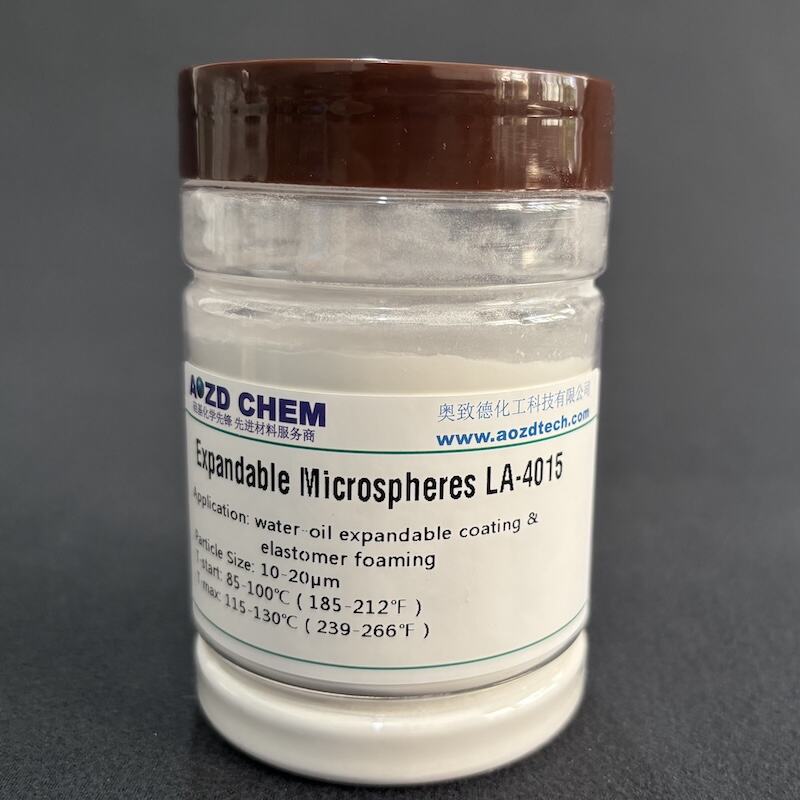

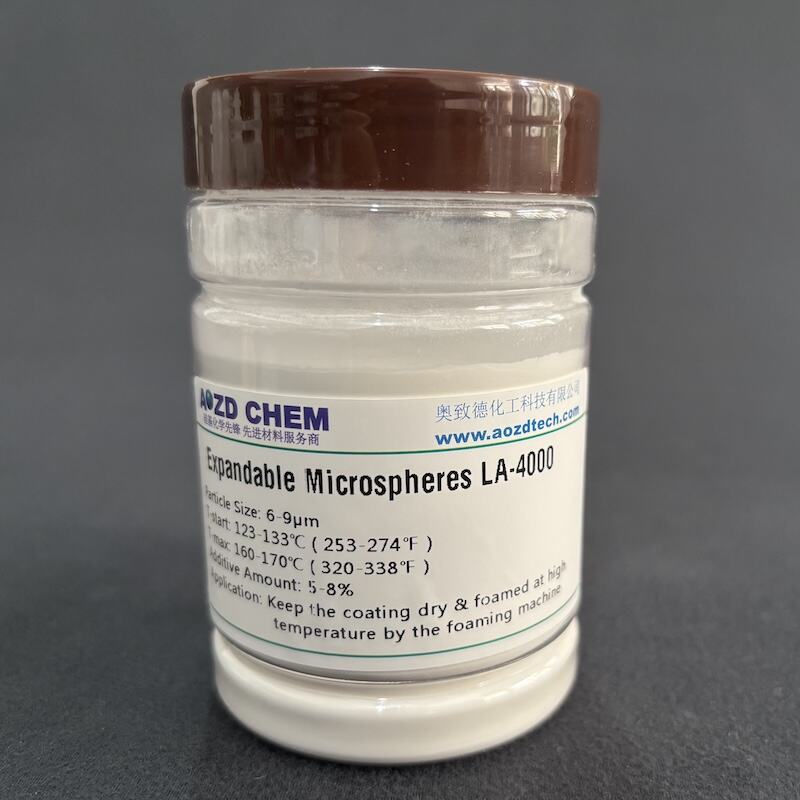

expancel microspheres

Expancel microspheres represent a groundbreaking innovation in polymer technology, consisting of tiny spherical particles with a thermoplastic shell encapsulating a hydrocarbon gas. When exposed to heat, these microspheres undergo a remarkable transformation, expanding up to 40 times their original volume while maintaining their lightweight properties. This unique characteristic makes them invaluable in various industrial applications. The microspheres are engineered with precise control over their expansion temperature range, typically between 80°C and 190°C, allowing for optimal performance in different manufacturing processes. The technology behind these microspheres involves sophisticated polymer chemistry, resulting in products that offer consistent quality and reliable performance. These versatile particles can be incorporated into various materials, including plastics, coatings, sealants, and adhesives, where they contribute to weight reduction, thermal insulation, and enhanced material properties. Their closed-cell structure ensures stability and durability in final applications, while their uniform particle size distribution enables predictable and controlled expansion behavior.