expancel microspheres made in china

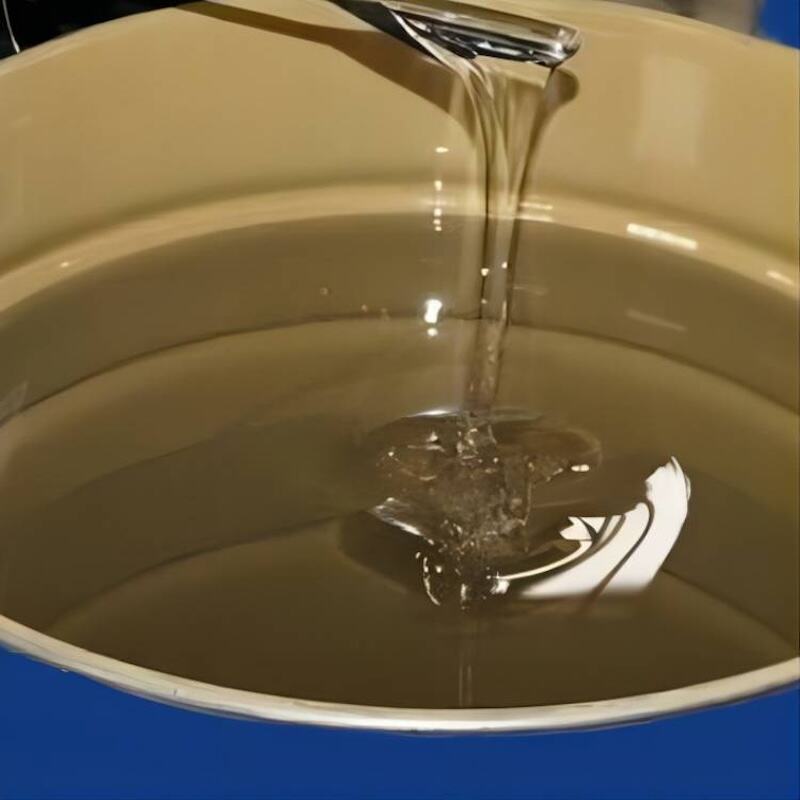

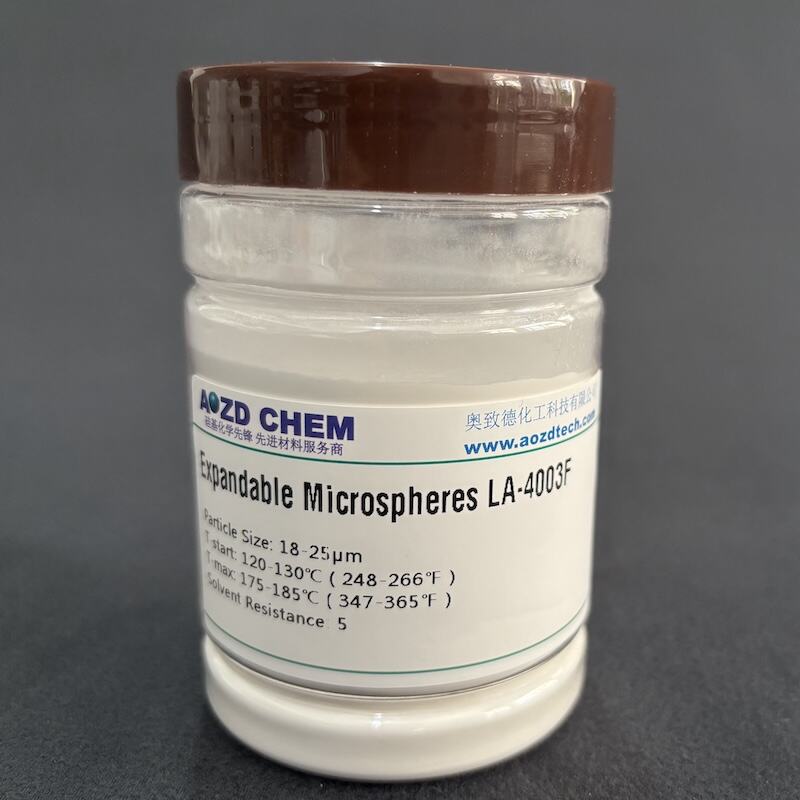

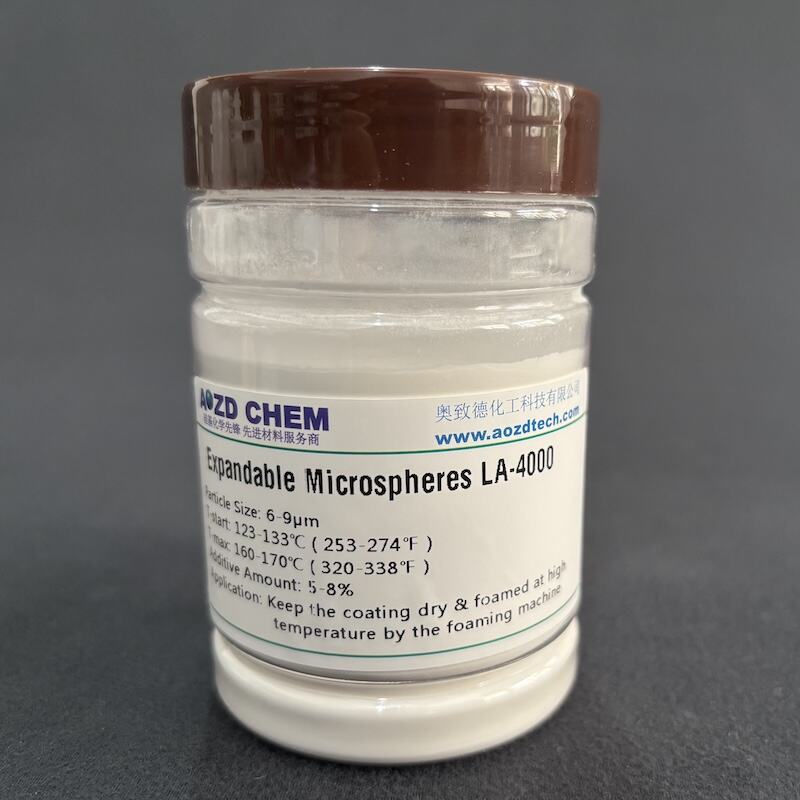

Expancel microspheres made in China represent a groundbreaking advancement in polymer technology, offering exceptional versatility and performance across various industrial applications. These microspheres are tiny plastic spheres containing hydrocarbon gas, engineered to expand dramatically when heated. Manufactured using state-of-the-art production facilities in China, these microspheres typically range from 10 to 40 microns in their unexpanded state and can expand up to 60 times their original volume when activated. The production process involves sophisticated emulsion polymerization techniques, ensuring consistent quality and reliable performance. These microspheres serve multiple functions, including weight reduction in compounds, thermal insulation enhancement, and density control in various materials. They are particularly valuable in industries such as automotive, construction, and packaging, where they contribute to product lightweighting and improved thermal properties. The Chinese manufacturing process emphasizes quality control while maintaining cost-effectiveness, making these microspheres an attractive option for global markets. The material composition typically includes a thermoplastic polymer shell containing a blowing agent, which enables the characteristic expansion when exposed to heat.