expancel microspheres factory

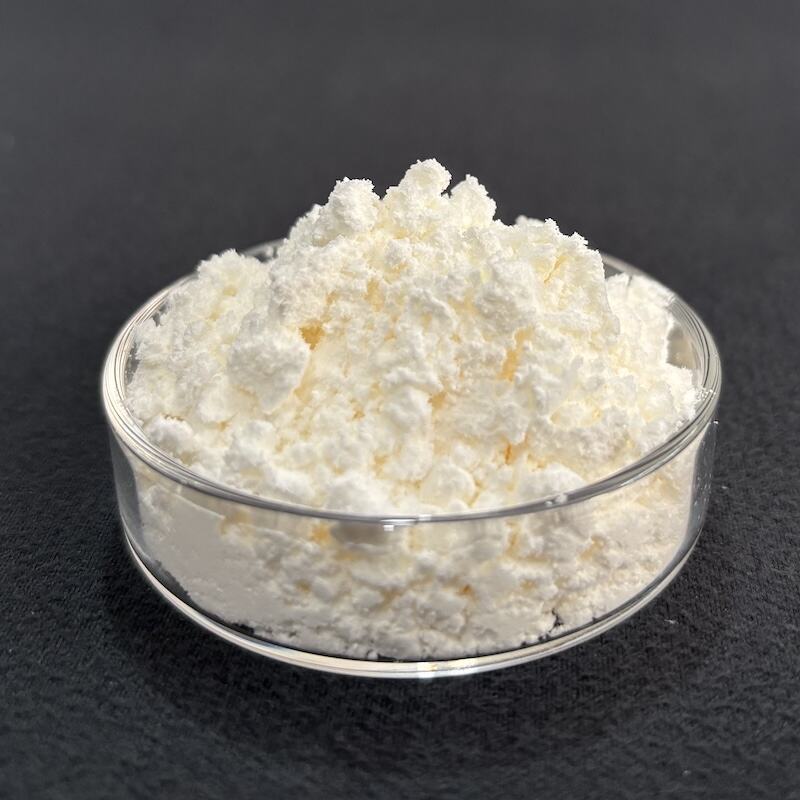

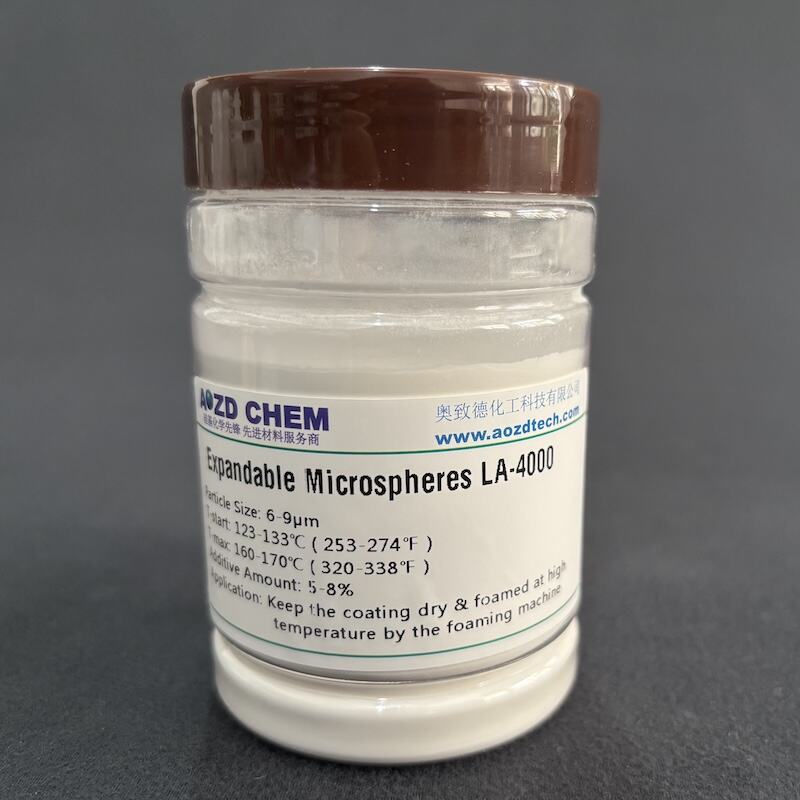

The expancel microspheres factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality thermoplastic microspheres with exceptional expansion capabilities. This cutting-edge facility employs advanced production technology to create microspheres that consist of a thermoplastic shell encapsulating a hydrocarbon gas. When heated, these microspheres expand dramatically, increasing in volume up to 40 times their original size while maintaining minimal weight. The factory integrates automated production lines with precise control systems to ensure consistent quality and uniform particle size distribution. The facility features specialized polymer processing equipment, temperature-controlled reaction vessels, and advanced separation systems that enable the production of microspheres with varying expansion temperatures and particle sizes. Quality control laboratories equipped with sophisticated analytical instruments continuously monitor product specifications and performance characteristics. The factory implements sustainable manufacturing practices, including efficient energy management systems and waste reduction protocols. With its comprehensive production capabilities, the facility serves diverse industries including automotive, construction, packaging, and specialty materials, providing customized solutions for specific application requirements.