expancel microspheres manufacturer

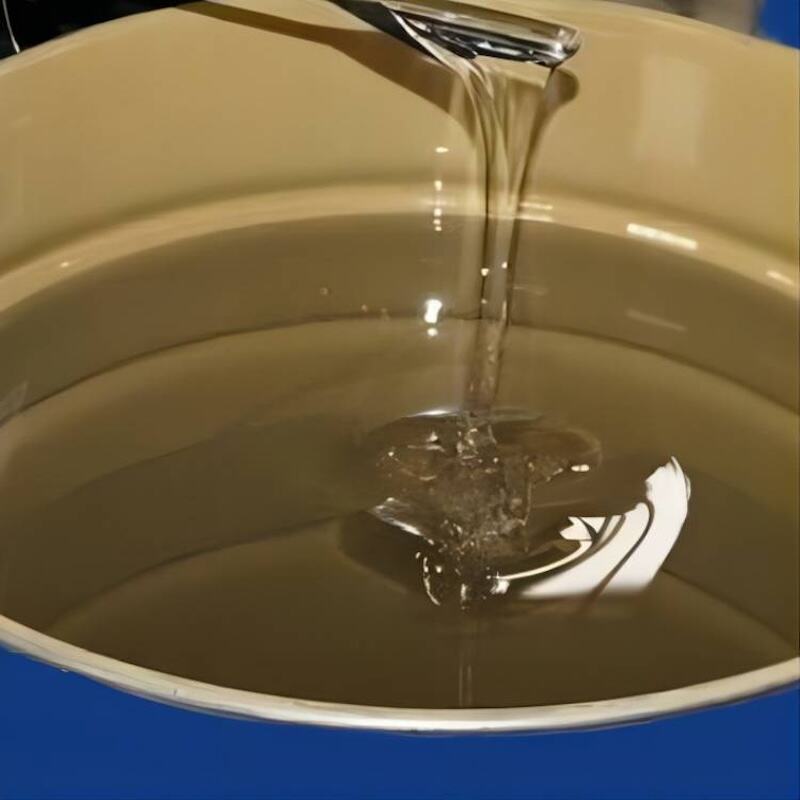

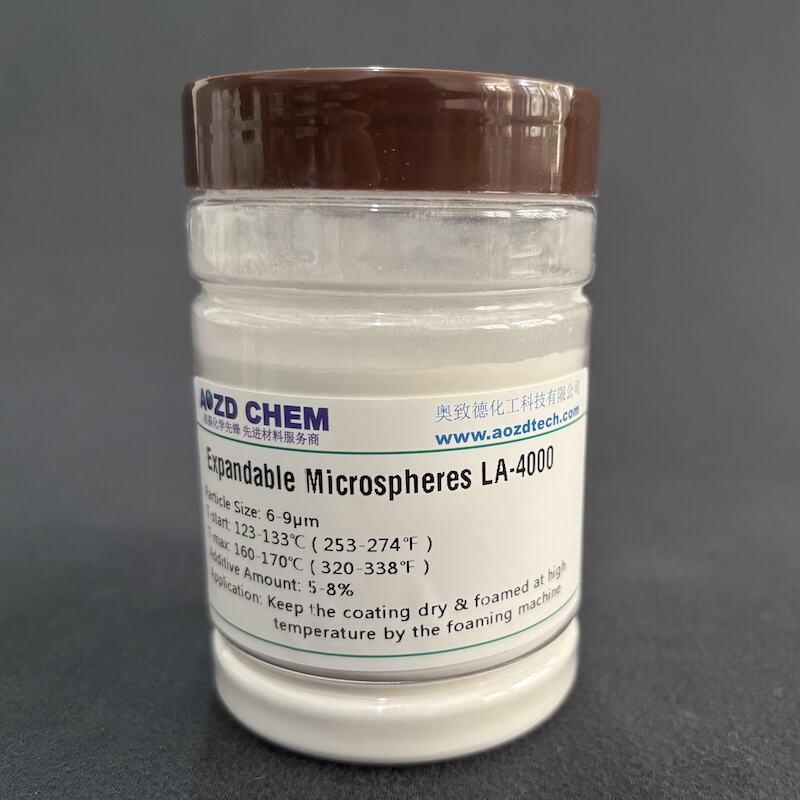

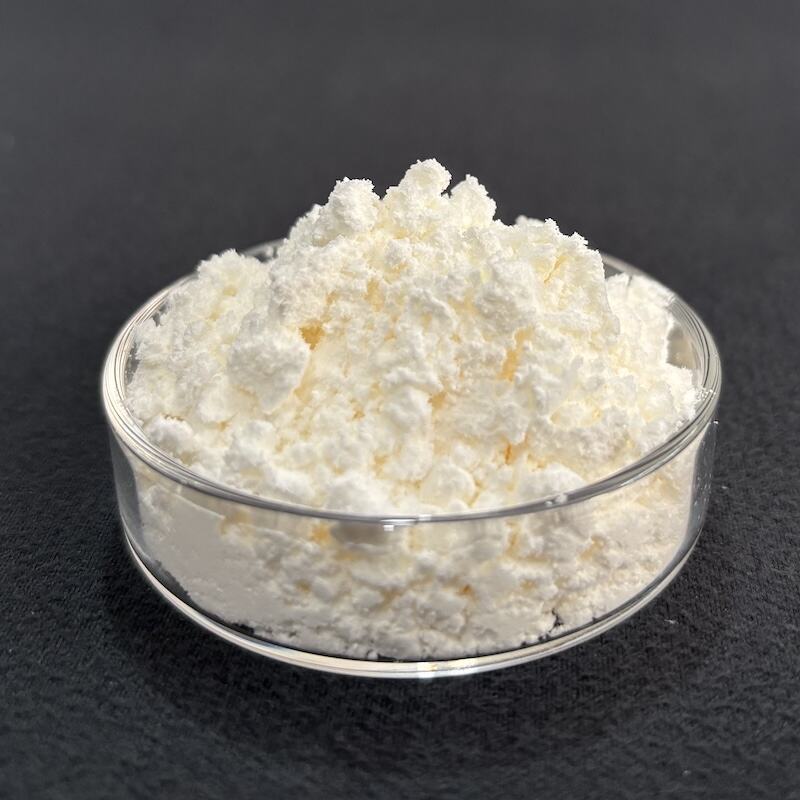

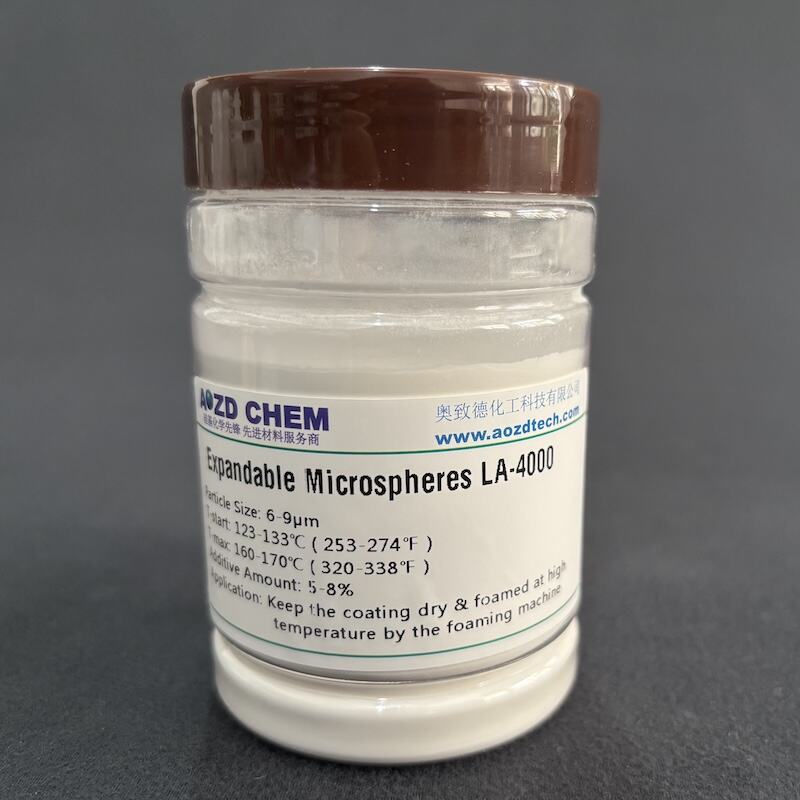

An expancel microspheres manufacturer specializes in producing advanced thermoplastic microspheres that revolutionize various industrial applications. These microspheres consist of a thermoplastic polymer shell encapsulating a hydrocarbon gas, engineered to expand significantly when heated. The manufacturing process involves sophisticated polymer technology and precise control systems to ensure consistent product quality. These facilities employ state-of-the-art equipment for polymerization, size classification, and quality control, enabling the production of microspheres with specific characteristics such as expansion temperature, particle size distribution, and density. The manufacturer maintains strict quality control measures throughout the production process, from raw material selection to final product testing. Their production capabilities typically include both unexpanded and pre-expanded microspheres, available in various grades to meet different application requirements. The manufacturing facility incorporates automated systems for material handling, process control, and packaging, ensuring product consistency and minimizing contamination risks. Advanced research and development laboratories within the facility continue to innovate and improve product performance, working closely with customers to develop customized solutions for specific applications in industries ranging from automotive to construction.