cheapest expancel microspheres

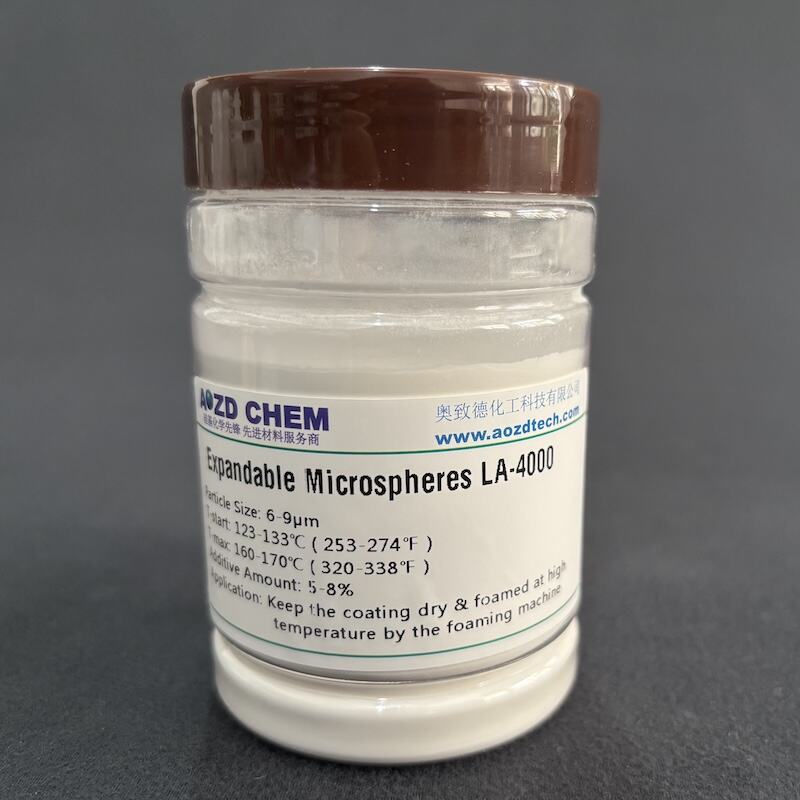

Expancel microspheres represent a cost-effective solution in the world of expandable thermoplastic materials. These lightweight, hollow spherical particles consist of a polymer shell encapsulating a hydrocarbon gas. When exposed to heat, these microspheres expand dramatically, increasing in volume up to 40 times their original size while maintaining minimal weight. The cheapest expancel microspheres offer an economical alternative without compromising essential performance characteristics. They typically range in size from 10 to 40 microns before expansion and can reach sizes of up to 120 microns post-expansion. These microspheres find extensive applications in various industries, including automotive, construction, and packaging. They serve as effective lightweight fillers, providing thermal insulation, density reduction, and improved material properties. The manufacturing process involves suspension polymerization, creating a thermoplastic shell that softens at specific temperatures, allowing the encapsulated hydrocarbon to expand the sphere. Despite their budget-friendly nature, these microspheres maintain reliable expansion ratios and thermal stability, making them ideal for cost-sensitive applications where weight reduction and insulation properties are crucial.