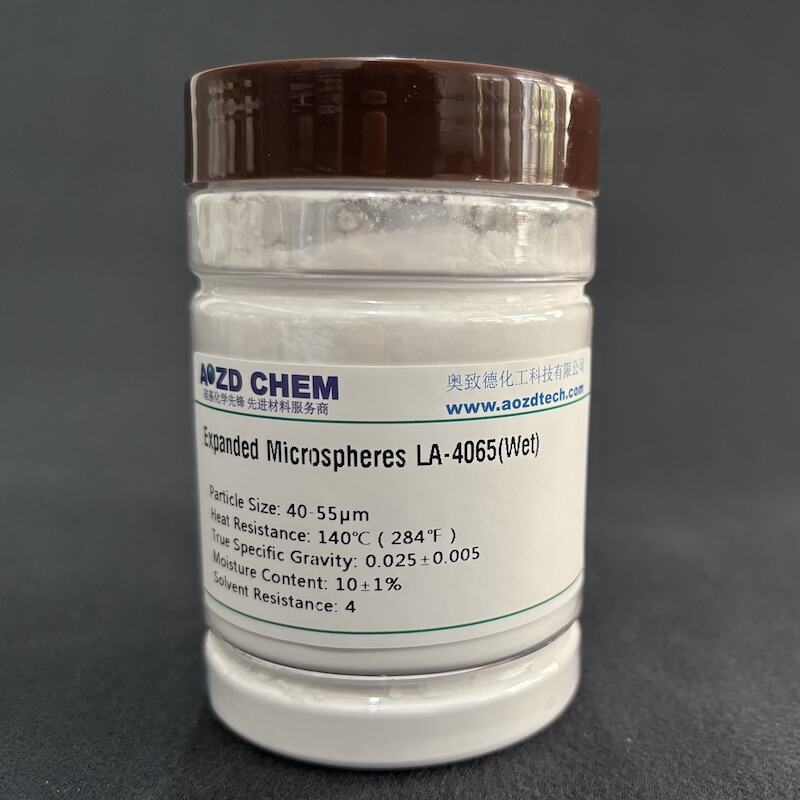

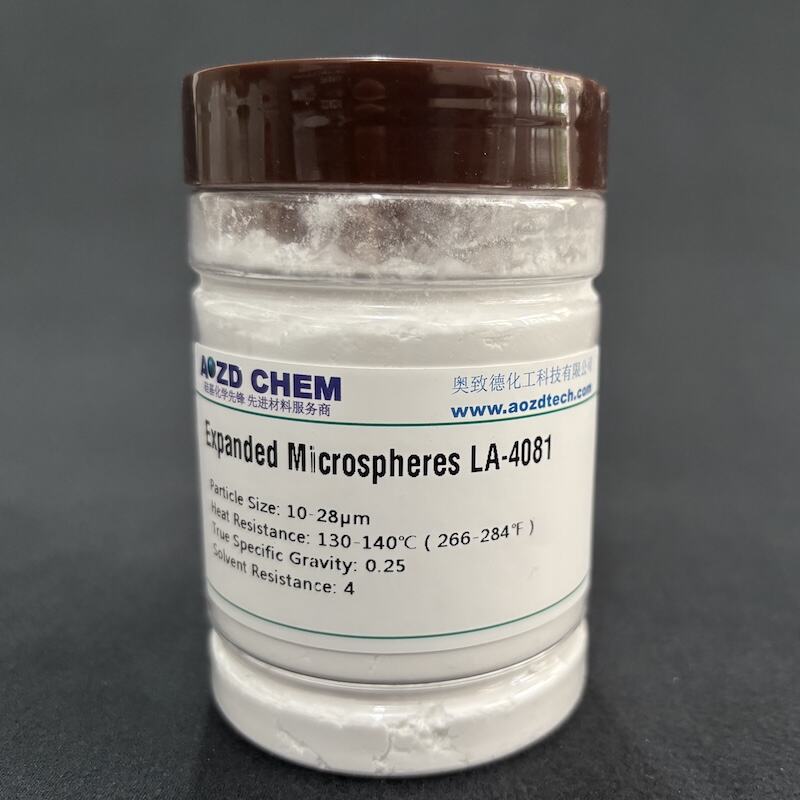

best expanded microspheres

Expanded microspheres represent a cutting-edge technological advancement in lightweight filler materials, characterized by their thermoplastic shells encapsulating hydrocarbon gas. When exposed to heat, these microscopic spheres expand dramatically, increasing up to 60 times their original size while maintaining incredibly low density. These remarkable particles typically range from 10 to 100 microns in diameter and feature excellent compressive strength, thermal insulation properties, and chemical resistance. Their unique structure combines hollow cores with robust outer shells, making them ideal for various industrial applications. The spheres demonstrate exceptional stability across a wide temperature range and maintain their expanded form indefinitely. In manufacturing processes, they significantly reduce material density without compromising structural integrity, offering substantial weight reduction in final products. Their closed-cell structure provides superior thermal insulation properties, making them essential in construction materials and automotive components. Additionally, their uniform particle size distribution ensures consistent performance across applications, from automotive parts to marine vessels, construction materials, and specialized coatings. The spheres' ability to withstand high pressures while maintaining their shape makes them particularly valuable in demanding industrial environments.