expanded microspheres manufacturer

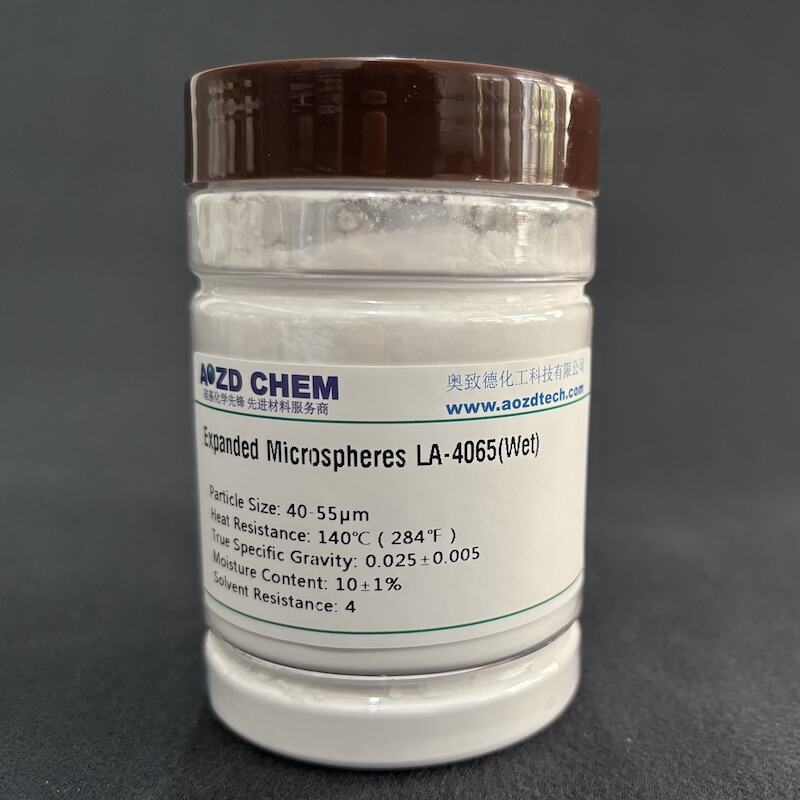

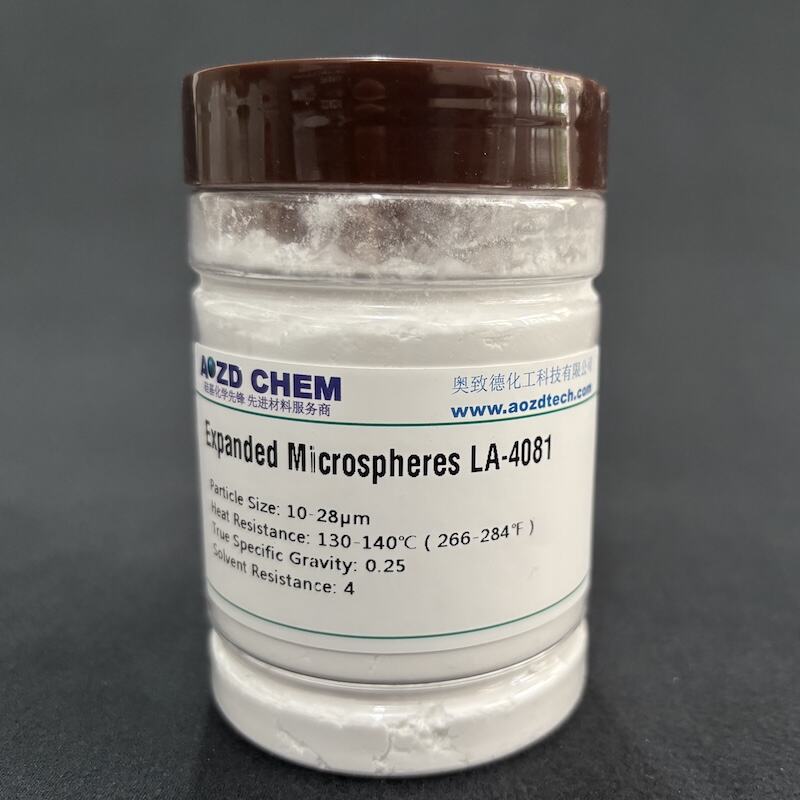

An expanded microspheres manufacturer specializes in producing lightweight, hollow particles that revolutionize various industrial applications. These sophisticated facilities employ cutting-edge technology to create thermoplastic microspheres filled with hydrocarbon gas. When exposed to heat, these particles expand dramatically, increasing in size while maintaining minimal density. The manufacturing process involves precise temperature control, advanced polymer science, and stringent quality assurance protocols to ensure consistent product quality. These facilities utilize state-of-the-art equipment for polymerization, expansion, and classification of microspheres, enabling the production of particles with specific size distributions and expansion ratios. The manufacturing plants incorporate automated systems for material handling, process control, and product testing, ensuring efficient production and consistent quality. Modern expanded microspheres manufacturers also emphasize sustainability, implementing energy-efficient processes and waste reduction measures. Their production capabilities typically include various grades of microspheres, from standard to specialty products, catering to diverse industrial needs such as construction materials, automotive components, packaging, and specialty coatings. The facilities maintain advanced research and development departments to continuously improve product performance and develop new applications.