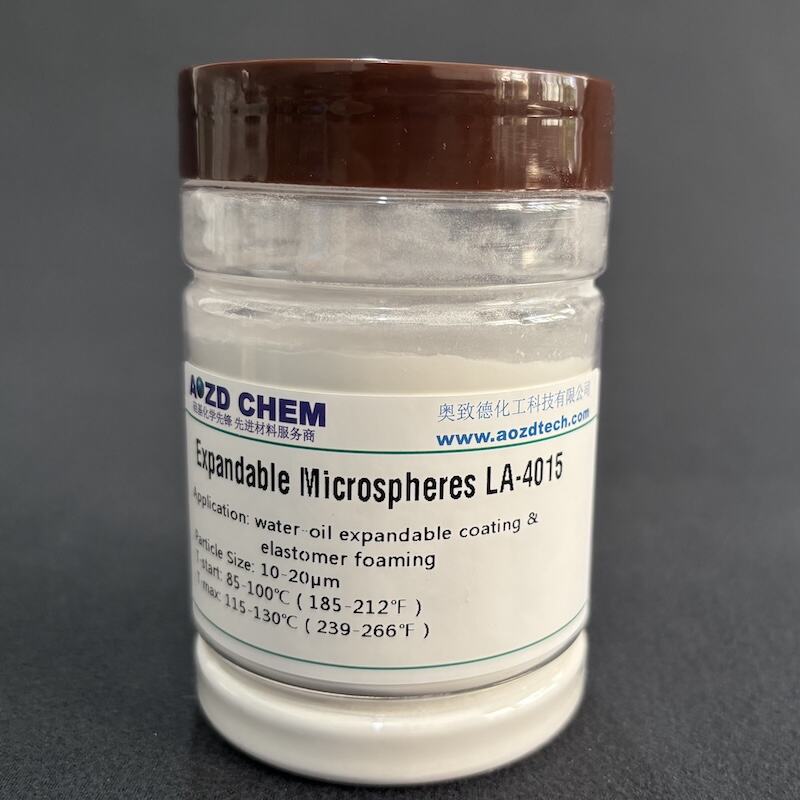

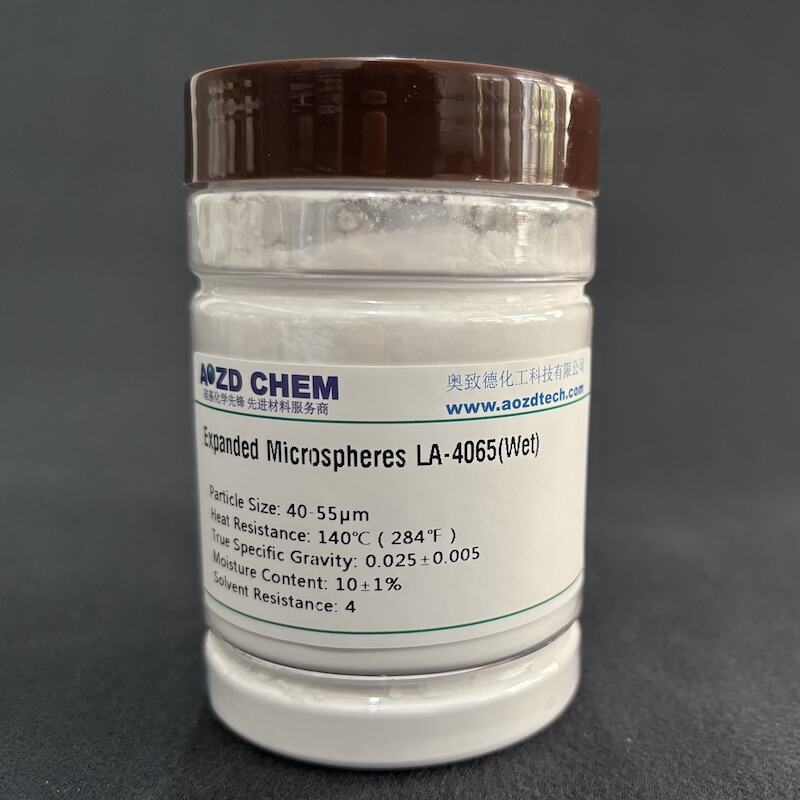

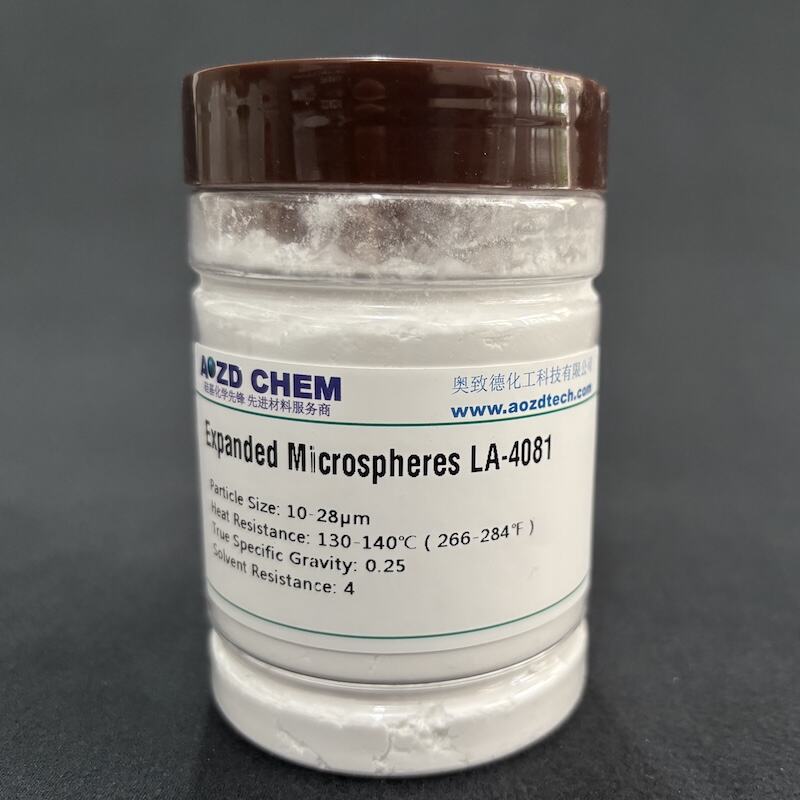

expanded microspheres supplier

An expanded microspheres supplier serves as a critical partner in providing specialized hollow thermoplastic spheres filled with hydrocarbon gas. These microspheres, typically ranging from 20 to 150 microns in diameter, undergo a unique expansion process when exposed to heat, increasing their volume by up to 60 times while maintaining minimal weight. The supplier ensures consistent quality control throughout the manufacturing process, utilizing advanced production technologies and stringent testing protocols. Their facilities incorporate state-of-the-art equipment for precise particle size distribution, density control, and thermal resistance optimization. These suppliers maintain extensive research and development capabilities, continuously improving product formulations to meet evolving industry demands. The microspheres find applications across diverse sectors, including automotive lightweight materials, construction insulation, synthetic wood manufacturing, and advanced coating systems. Suppliers often provide customized solutions, adjusting particle size distributions, expansion temperatures, and surface treatments to meet specific application requirements. They maintain robust supply chain networks to ensure reliable delivery and often offer technical support services to help customers optimize their manufacturing processes.