cheapest expanded microspheres

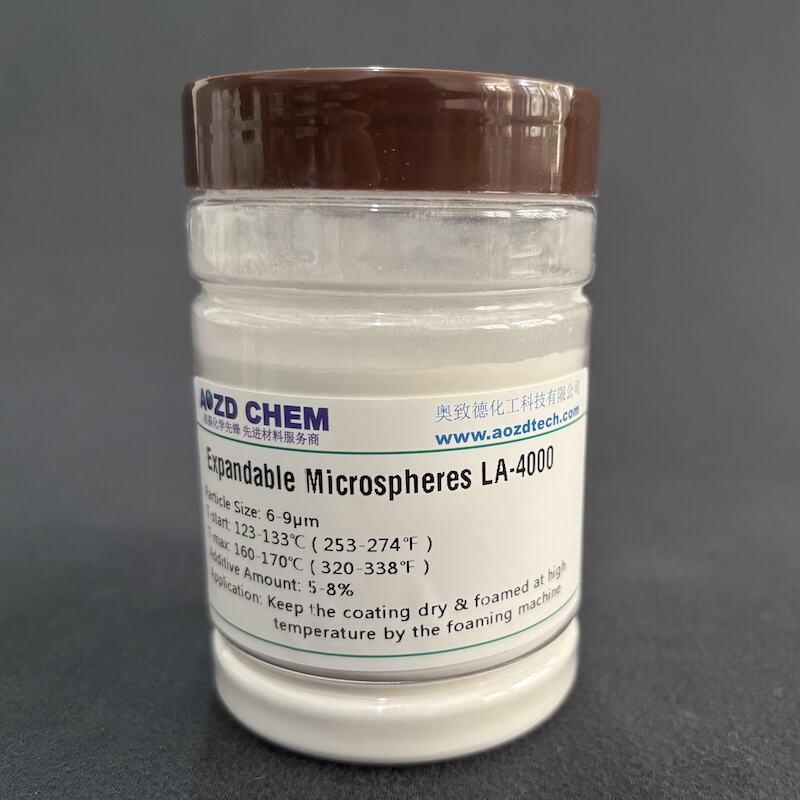

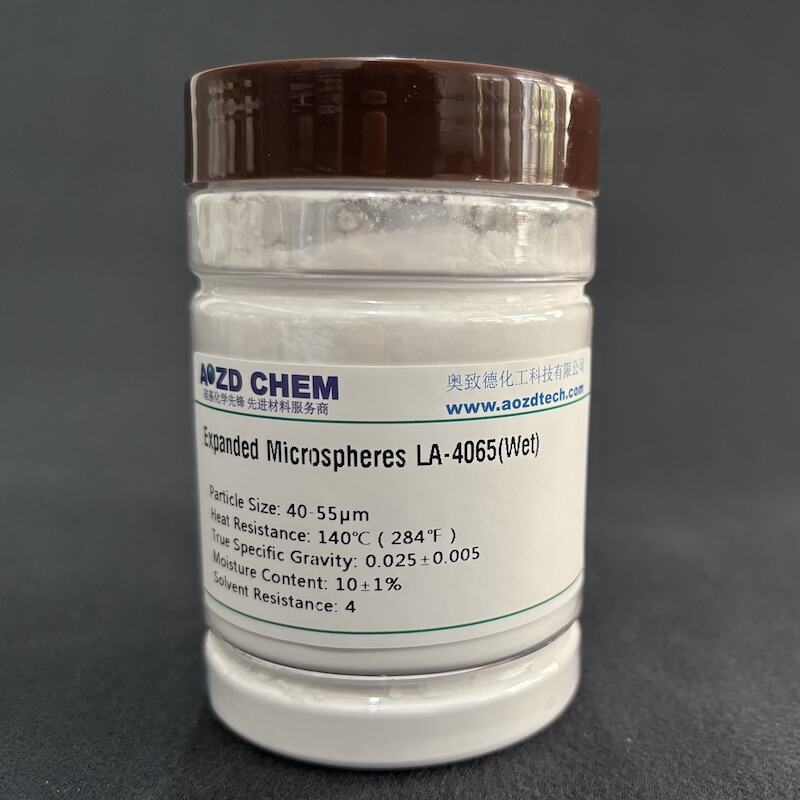

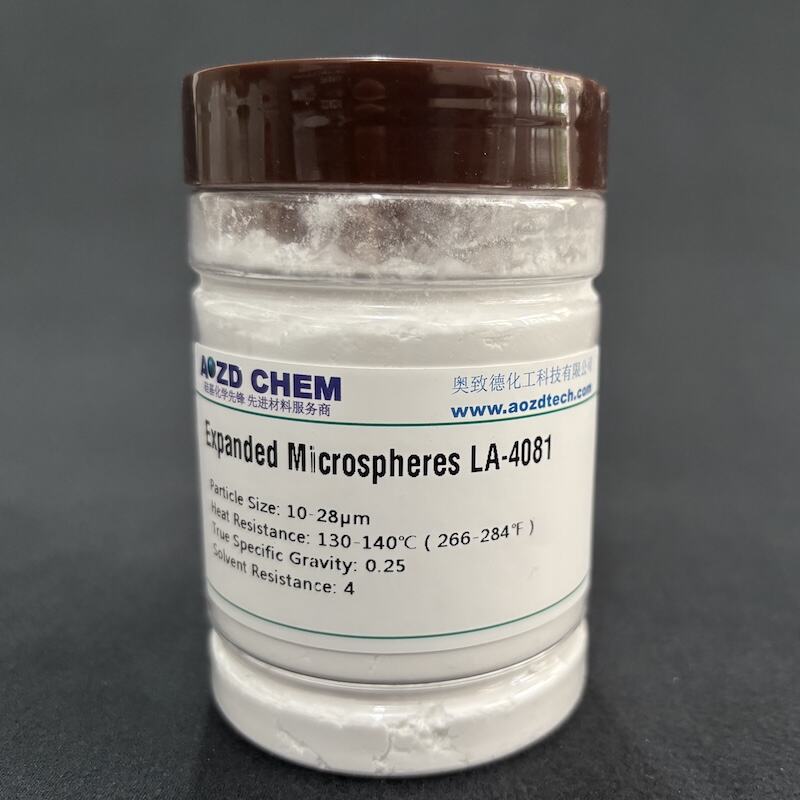

Expanded microspheres represent a cost-effective solution in various industrial applications, offering exceptional lightweight properties and versatile functionality. These hollow particles, typically composed of a thermoplastic shell encapsulating a hydrocarbon blowing agent, expand significantly when heated. The cheapest expanded microspheres available in the market maintain essential performance characteristics while providing economic advantages for manufacturers. These microspheres feature a particle size ranging from 10 to 100 microns and can expand up to 60 times their original volume when exposed to temperatures between 80°C and 190°C. Their low density, typically ranging from 0.02 to 0.13 g/cm3, makes them ideal for lightweight applications. The spheres demonstrate excellent compatibility with various materials, including adhesives, sealants, plastics, and coatings. In construction applications, they serve as effective lightweight fillers, reducing overall material density while maintaining structural integrity. The automotive industry utilizes these microspheres in underbody coatings and interior components to achieve weight reduction and improve fuel efficiency. Additionally, these cost-effective expanded microspheres find applications in printing inks, where they provide texture and dimensional stability to printed materials.