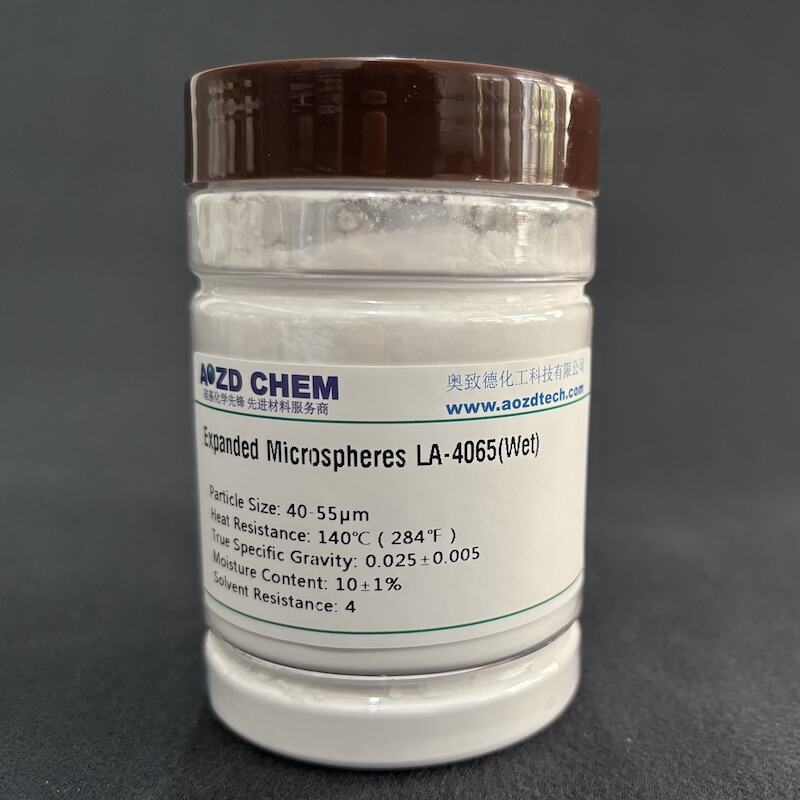

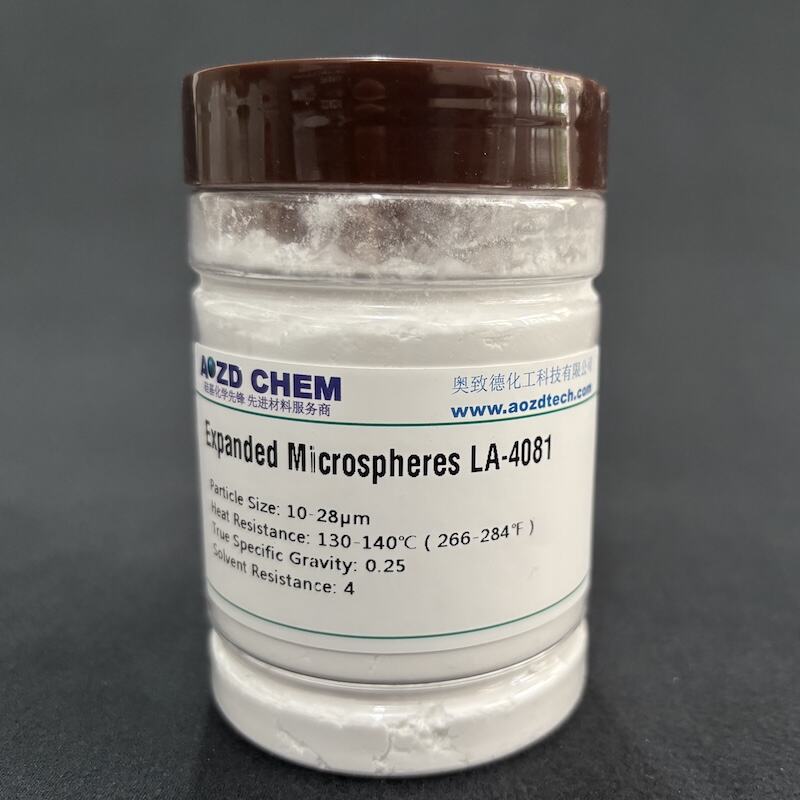

expanded microspheres foaming agent

Expanded microspheres foaming agent represents a cutting-edge solution in the field of polymer modification and lightweight material production. This innovative agent consists of thermoplastic microspheres containing encapsulated hydrocarbons that expand significantly when exposed to heat. When activated at specific temperatures, these microspheres can expand up to 50 times their original volume, creating a unique cellular structure within the host material. The technology behind expanded microspheres allows for precise control over density reduction and thermal insulation properties, making it invaluable across various industrial applications. These agents are particularly effective in producing lightweight composites, reducing material density while maintaining structural integrity. The microspheres remain stable after expansion, providing lasting performance benefits in end products. Their closed-cell structure ensures excellent moisture resistance and consistent thermal insulation properties. The agent's versatility allows for integration into various manufacturing processes, including injection molding, extrusion, and coating applications. Notable features include uniform cell distribution, controlled expansion rates, and compatibility with numerous polymer matrices.