expanded microspheres made in china

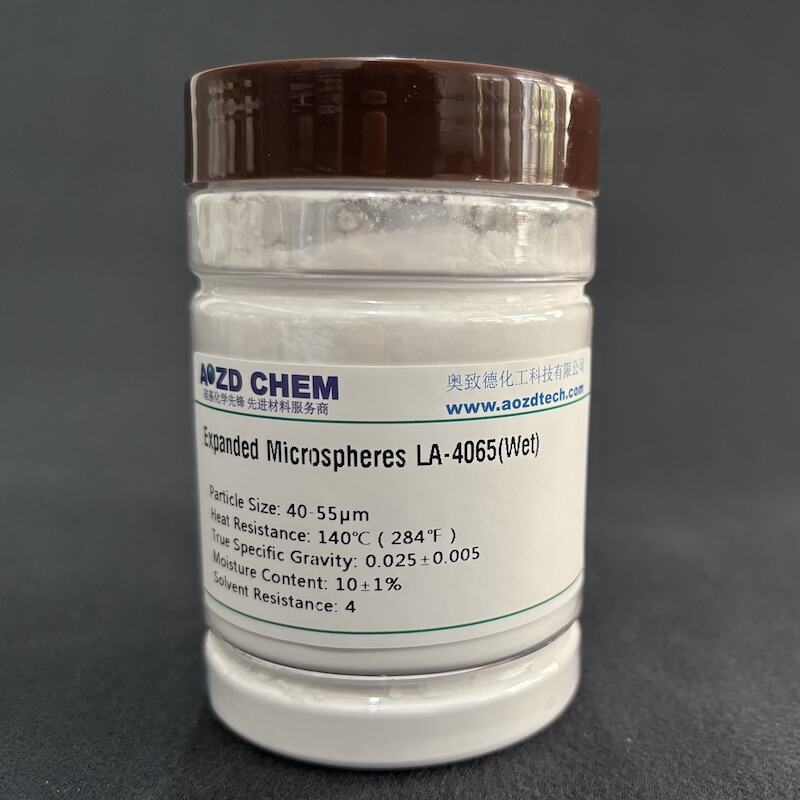

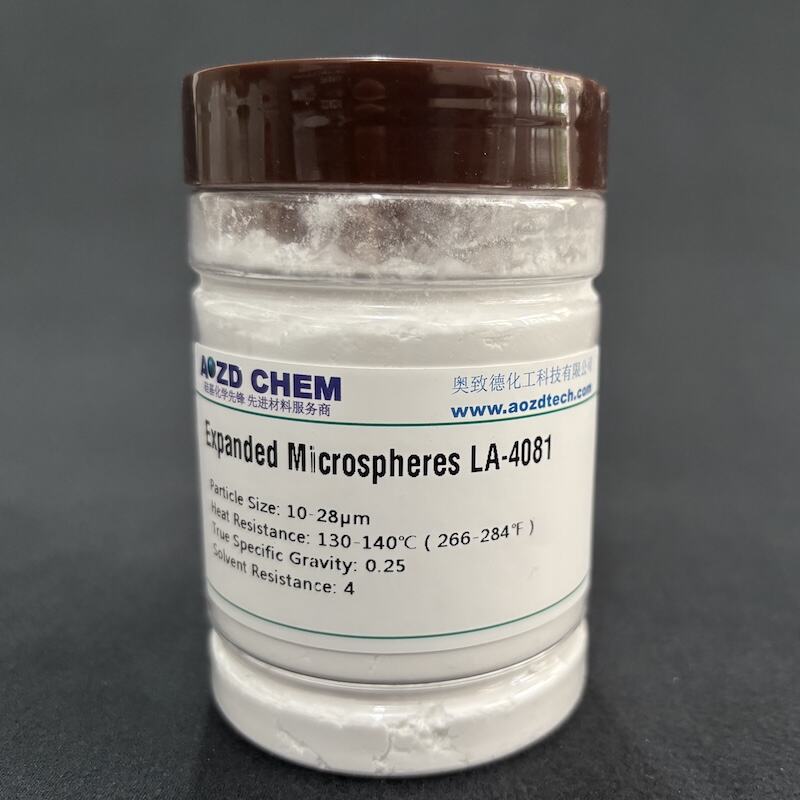

Expanded microspheres made in China represent a groundbreaking advancement in lightweight filler technology, featuring thermoplastic spherical particles filled with hydrocarbon gas. These microspheres undergo a sophisticated expansion process when exposed to heat, increasing their volume by up to 60 times while maintaining incredibly low density. The manufacturing process in China employs cutting-edge technology to ensure consistent quality and precise particle size distribution, typically ranging from 20 to 150 microns. These microspheres exhibit exceptional properties including excellent compressive strength, low thermal conductivity, and superior chemical resistance. Chinese manufacturers have optimized the production process to achieve a perfect balance between expansion ratio and structural integrity. The microspheres find extensive applications across various industries, including automotive parts, construction materials, coatings, and synthetic leather production. They significantly reduce the weight of end products while enhancing insulation properties and improving cost efficiency. The technology behind these microspheres continues to evolve, with Chinese manufacturers investing in research and development to enhance performance characteristics and expand application possibilities.