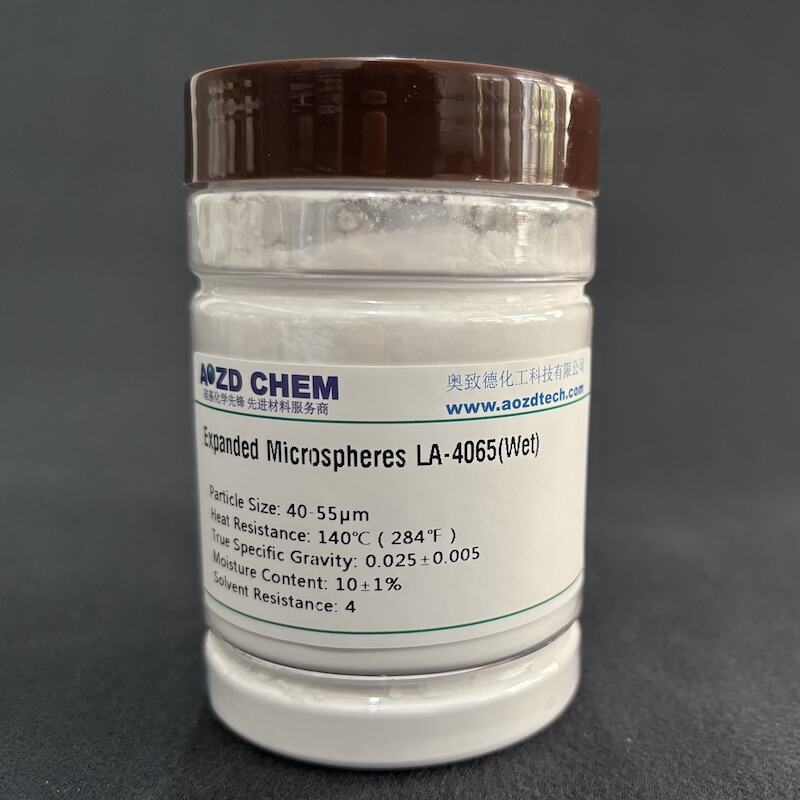

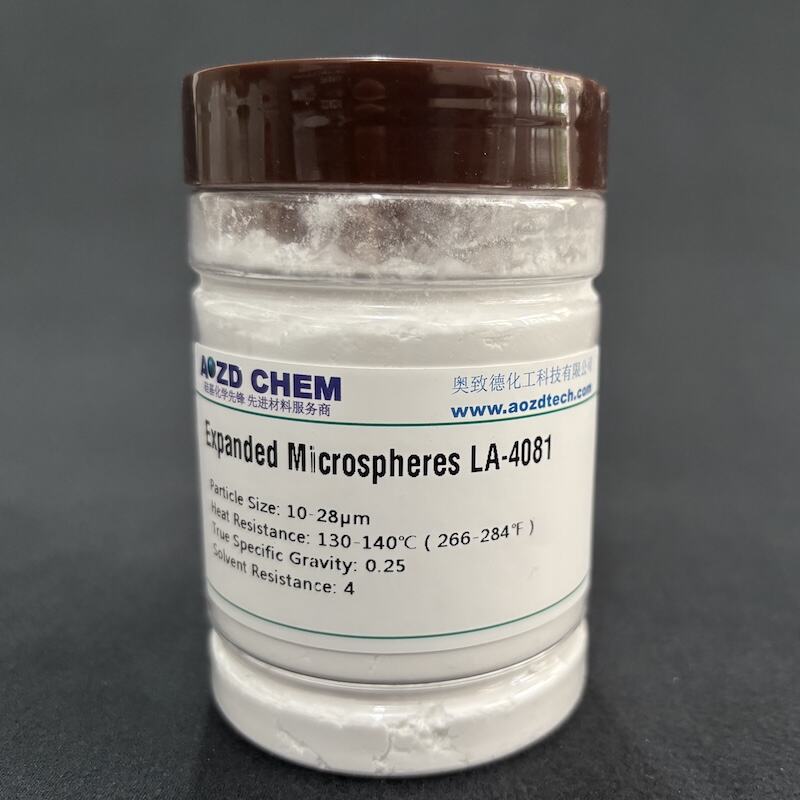

expanded microspheres for coatings

Expanded microspheres for coatings represent a groundbreaking innovation in the coating industry, offering exceptional performance characteristics and versatility. These lightweight, hollow spherical particles consist of a thermoplastic shell encapsulating a gas, providing unique properties that enhance coating formulations. When exposed to heat during processing, these microspheres expand significantly, creating a low-density material with excellent insulating properties. The technology behind expanded microspheres enables manufacturers to achieve superior coating performance while reducing overall material density. These microspheres function as highly effective lightweight fillers, providing thermal insulation, sound dampening, and improved rheological properties in various coating applications. Their closed-cell structure ensures excellent moisture resistance and durability, making them ideal for both indoor and outdoor applications. In industrial settings, expanded microspheres dramatically improve the performance of protective coatings, architectural finishes, and specialty coatings. Their ability to reduce weight while maintaining structural integrity has made them particularly valuable in automotive, aerospace, and marine applications. The controlled expansion process allows for precise material properties, ensuring consistent quality and reliable performance across different coating formulations.