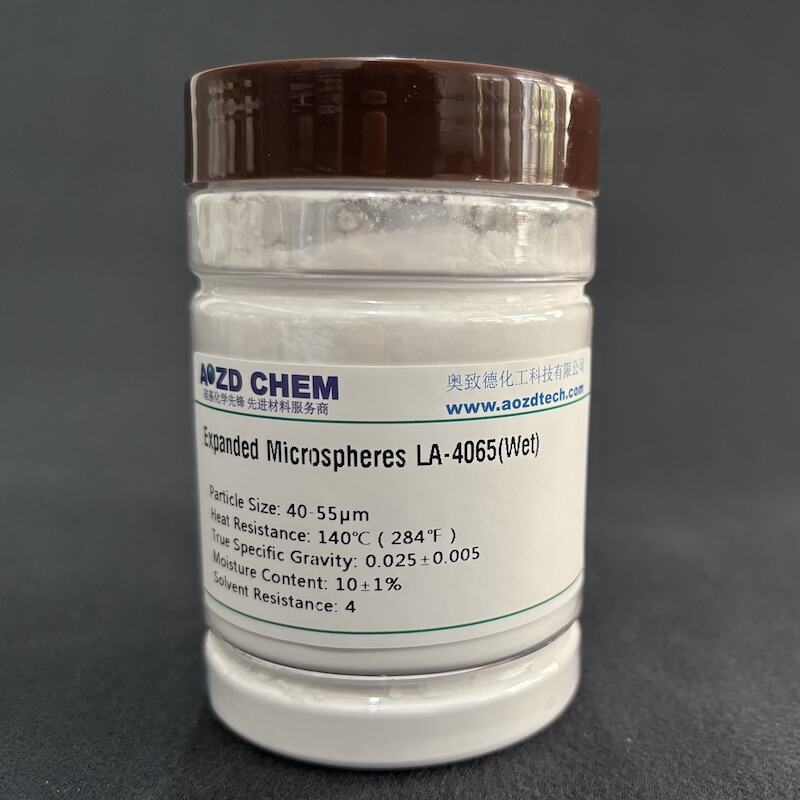

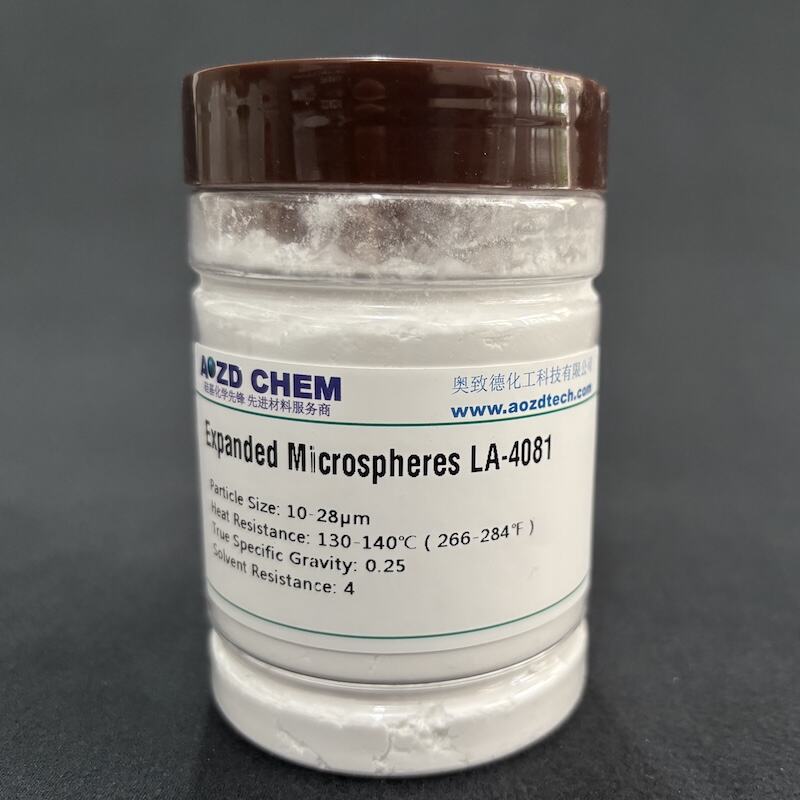

the expanded microspheres

Expanded microspheres represent a groundbreaking advancement in material science technology, consisting of tiny thermoplastic spheres filled with hydrocarbon gas. When exposed to heat, these microspheres expand dramatically, increasing up to 40 times their original volume while maintaining minimal weight. This unique characteristic makes them invaluable across various industrial applications. The spheres feature a thermoplastic shell that softens upon heating, allowing the encapsulated gas to expand and create a larger, low-density particle. These expanded microspheres typically range from 20 to 150 microns in diameter and possess exceptional properties including low thermal conductivity, high compressive strength, and excellent chemical resistance. They serve as crucial components in numerous applications, from lightweight fillers in plastics and coatings to thermal insulation materials. Their ability to reduce density while maintaining structural integrity makes them particularly valuable in automotive parts, construction materials, and specialty coatings. Additionally, their closed-cell structure ensures consistent performance and prevents moisture absorption, contributing to long-term product stability and reliability.