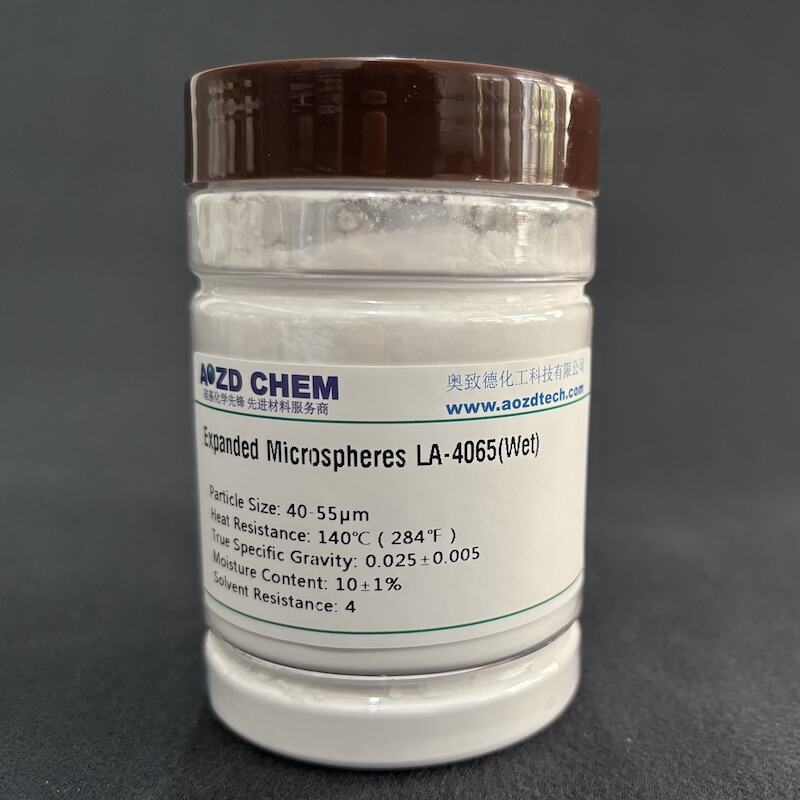

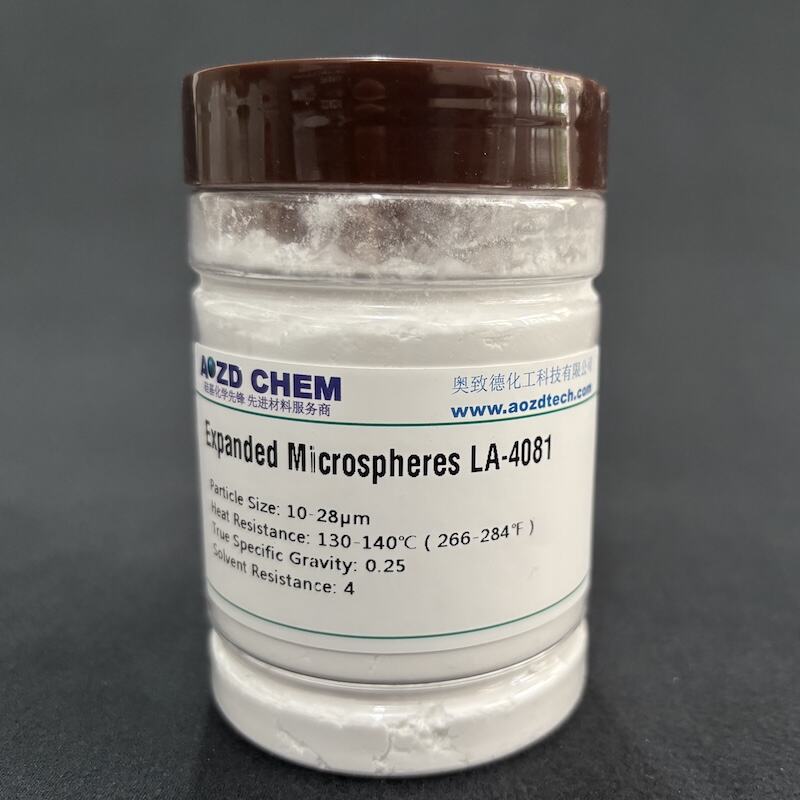

expanded microspheres for plastics

Expanded microspheres for plastics represent a groundbreaking innovation in polymer technology, offering exceptional lightweight properties and versatile functionality. These microscopic hollow spheres, typically composed of a thermoplastic shell encapsulating a gas, expand when exposed to heat during the manufacturing process. The technology behind these microspheres enables manufacturers to achieve significant weight reduction in plastic products while maintaining or even improving structural integrity. When incorporated into plastic matrices, these microspheres create a uniform cellular structure that enhances insulation properties and reduces material density by up to 65%. The spheres' expansion process is precisely controlled, allowing for customization of final product characteristics such as density, compression strength, and thermal conductivity. Applications span across numerous industries, including automotive parts manufacturing, building materials, marine products, and consumer goods. The microspheres' ability to distribute evenly throughout the polymer matrix ensures consistent product quality and performance. Furthermore, their closed-cell structure prevents moisture absorption and maintains long-term stability, making them ideal for demanding applications where weight reduction and insulation properties are crucial. The technology also contributes to cost efficiency by reducing material usage and improving processing characteristics.