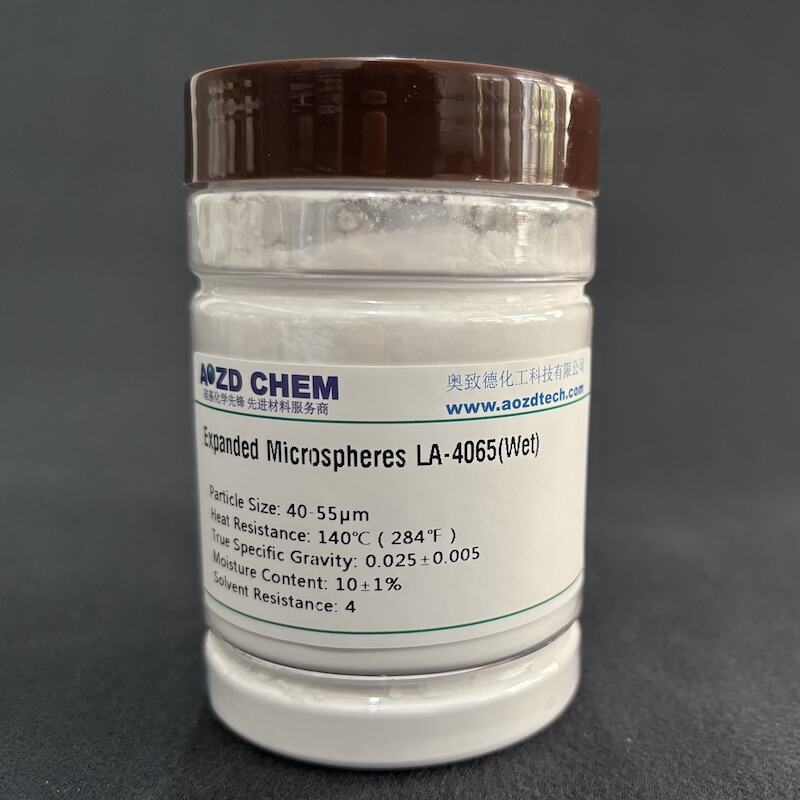

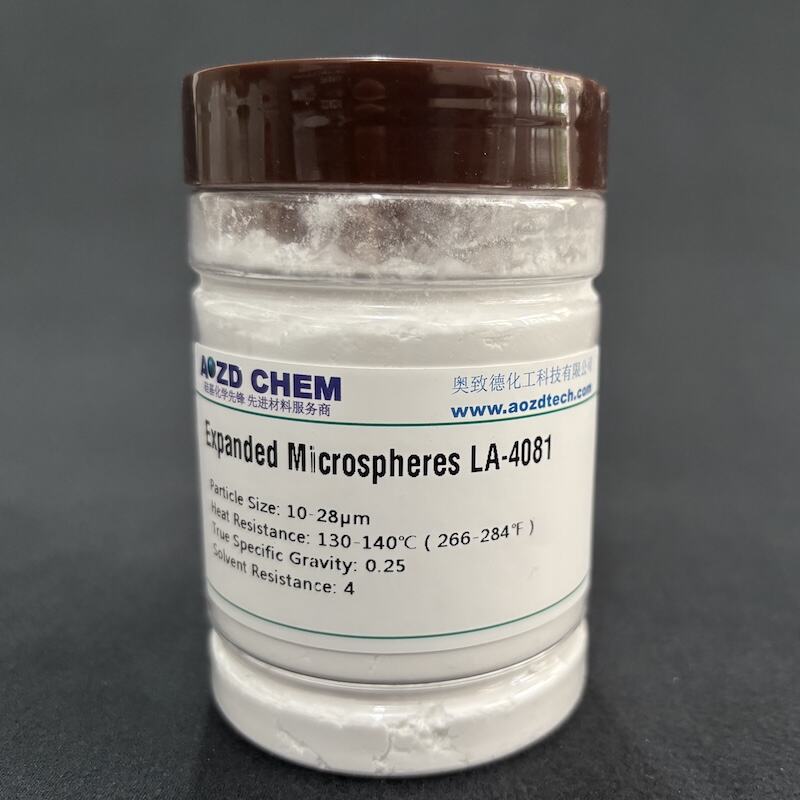

expanded microspheres factory

The expanded microspheres factory represents a cutting-edge manufacturing facility dedicated to producing high-quality expandable polymer microspheres. This state-of-the-art facility combines advanced production technology with precision control systems to create uniform, lightweight spherical particles. The factory utilizes specialized expansion chambers where thermoplastic shells containing hydrocarbon blowing agents are heated to precise temperatures, causing controlled expansion of the microspheres. The production line features automated quality control systems that monitor size distribution, expansion ratios, and particle integrity throughout the manufacturing process. With multiple production lines operating simultaneously, the facility can accommodate various product specifications, from ultra-low density variants to specialized pressure-resistant grades. The factory incorporates environmentally conscious manufacturing practices, including closed-loop cooling systems and efficient material recovery processes. Advanced sorting and classification equipment ensures precise particle size distribution, while sophisticated coating systems enable surface modification for specific applications. The facility's capabilities extend to producing microspheres for various industries, including automotive, construction, packaging, and specialty materials. Quality control laboratories equipped with advanced analytical instruments ensure consistent product quality and compliance with international standards.